Multilayer electrode, preparation method of multilayer electrode and lithium ion battery

A lithium-ion battery and multi-layer electrode technology, which is applied in the direction of electrode manufacturing, electrode collector coating, electrode carrier/collector, etc., can solve the problems of lithium analysis and other performance attenuation, large expansion effect of conductive layer, etc., and achieve reduction Expansion effect, high energy density and charging rate, effect of increasing charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

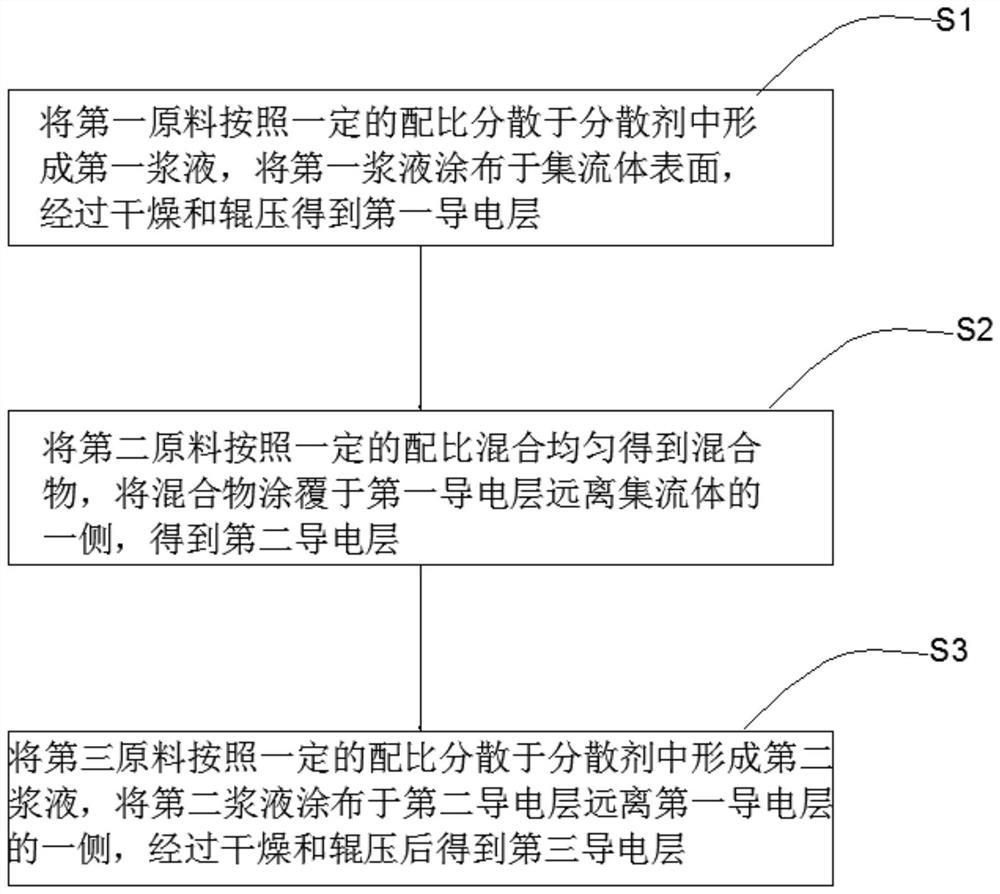

[0056] The embodiment of the application of the present invention also provides a method for preparing a multilayer electrode, such as figure 2 shown, including the following steps:

[0057] S1. Dispersing the first raw material in the first dispersant to form the first slurry, coating the first slurry on the surface of the current collector 1, drying and rolling to obtain the first conductive layer;

[0058] S2. Mix the second raw materials uniformly to obtain a mixture, and apply the mixture on the side of the first conductive layer away from the current collector 1 to obtain a second conductive layer.

[0059] The first raw material includes: a first active material, a first conductive agent and a first binder; the first dispersant is selected from one of water or nitrogen methyl pyrrolidone.

[0060] The second raw material includes: a second active material, a second conductive agent and a second binder.

[0061] Further, the mass percentage of the first active materia...

Embodiment 1

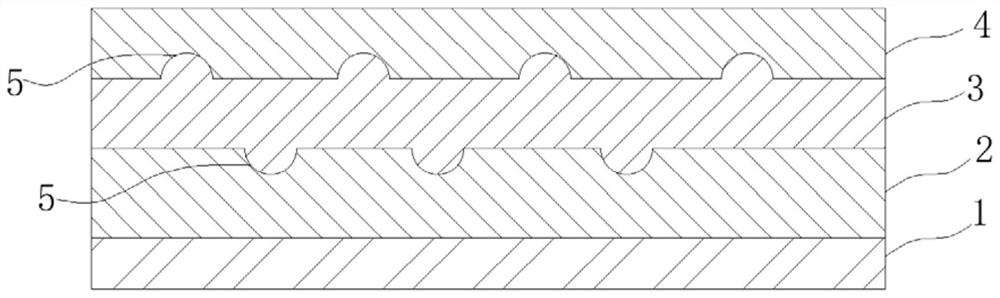

[0076] The current collector is nickel foil, and one surface of the current collector is coated with the first conductive layer, the second conductive layer and the third conductive layer in sequence. At this time, the first conductive layer and the third conductive layer are made by wet process, and the second The conductive layer is made by dry process. A riveted structure is formed between the first conductive layer and the second conductive layer, and a riveted structure is formed between the second conductive layer and the third conductive layer. The riveted structure is: because the first conductive layer and the third conductive layer are prepared by a wet process , the structure is relatively fluffy, when forming a multi-layer electrode with the second conductive layer, the second conductive layer will be partially embedded in the first conductive layer and the third conductive layer.

[0077] Preliminarily mixing graphite as the first active material, carbon black as ...

Embodiment 2

[0082] The current collector is copper foil, and one surface of the current collector is coated with the first conductive layer, the second conductive layer and the third conductive layer in sequence. At this time, the first conductive layer and the third conductive layer are made by wet process, and the second conductive layer The layers are made by dry process. A riveting structure is formed between the first conductive layer and the second conductive layer, and a riveting structure is formed between the second conductive layer and the third conductive layer.

[0083] Preliminarily mixing graphite as the first active material, carbon black as the first conductive agent, and polyacrylic acid as the first binder to obtain a mixture, adding water to the mixture as the first dispersant; stirring evenly to form a mixed slurry; The obtained slurry is coated on the current collector, and dried and rolled to obtain the first conductive layer. The thickness of the first conductive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com