A self-expanding anti-seepage seal for oil extraction equipment

A technology for oil extraction and self-expansion, applied in mechanical equipment, engine sealing, engine components, etc., can solve the problems of huge manpower and material resources, high cost, and reduced performance of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

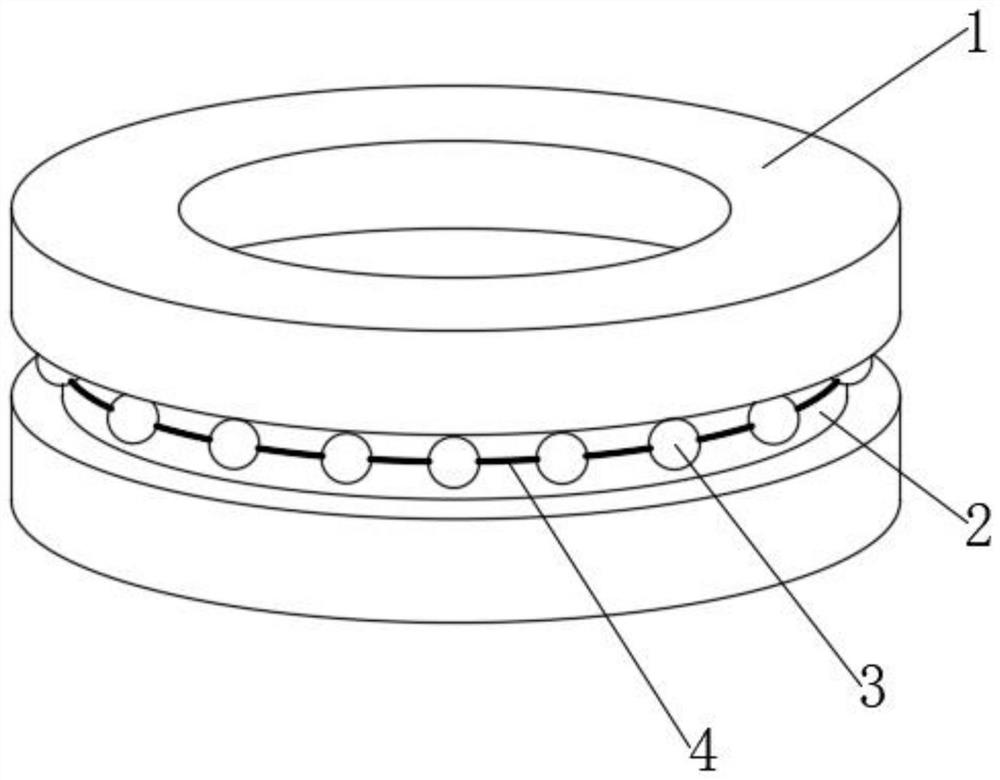

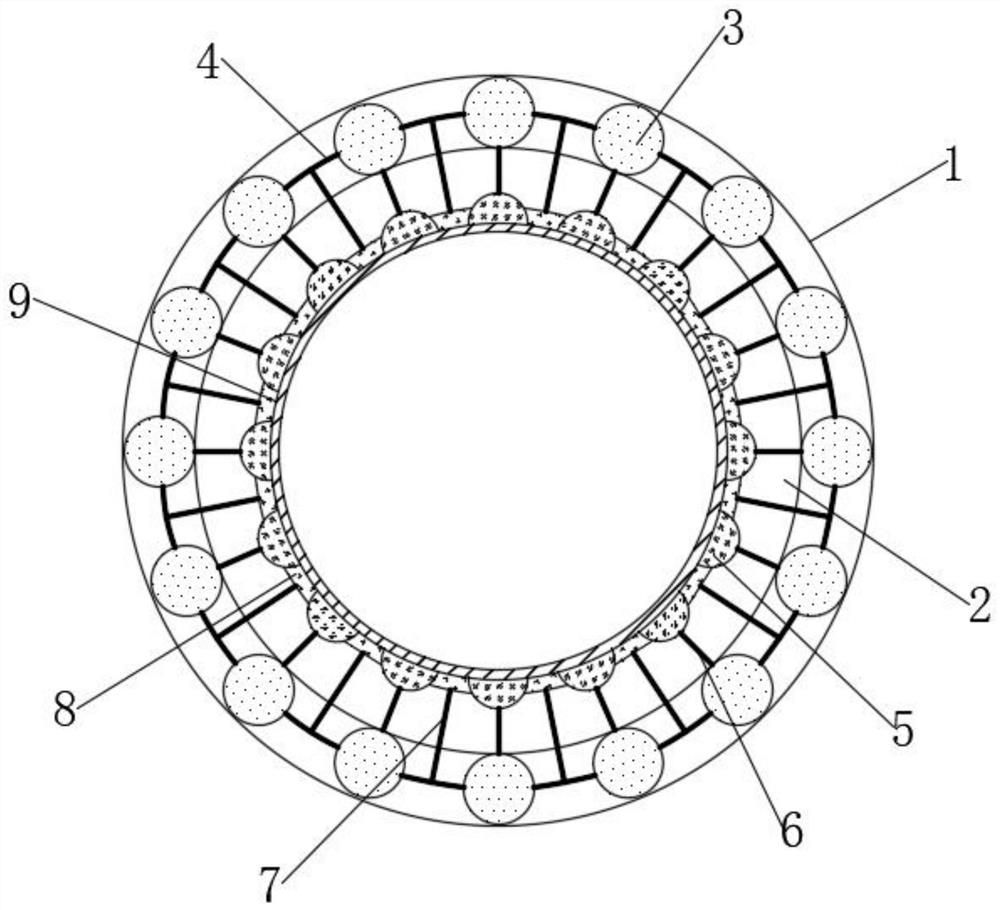

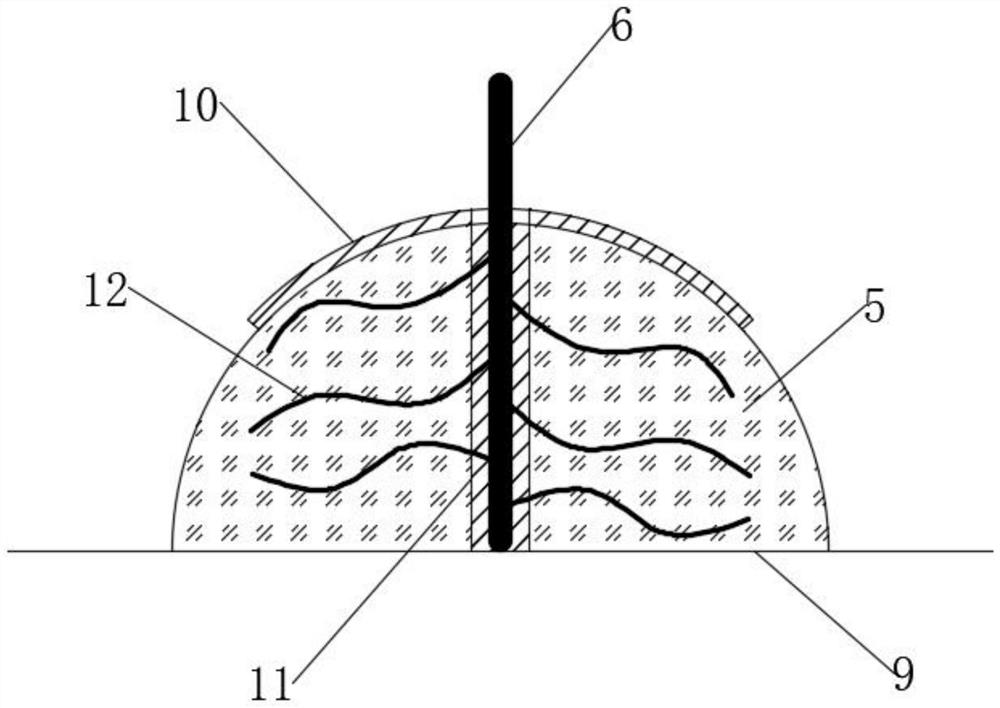

[0040] see Figure 1-2 , a self-expanding anti-seepage seal for oil extraction equipment, including a pair of edge sealing rings 1 and embedded sealing rings 2, the edge sealing ring 1 and the embedded sealing ring 2 are made of oil-resistant rubber, and the embedded sealing ring 2 is embedded between a pair of edge sealing rings 1, and the pair of edge sealing rings 1 and the embedded sealing ring 2 are integrally formed, and the outer surface of the embedded sealing ring 2 is fixedly connected with a plurality of permeable oil-absorbing balls 3 distributed in an annular array, The inner surface of the embedded sealing ring 2 is fixedly connected with the shaped fixed ring 9, which is made of hard material, and plays a role of supporting and shaping the embedded sealing ring 2 and the expansion limiting piece 10, and the shaped fixed ring 9 is close to the embedded One end of the middle sealing ring 2 is fixedly connected with a plurality of oil expansion trigger hemispheres ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com