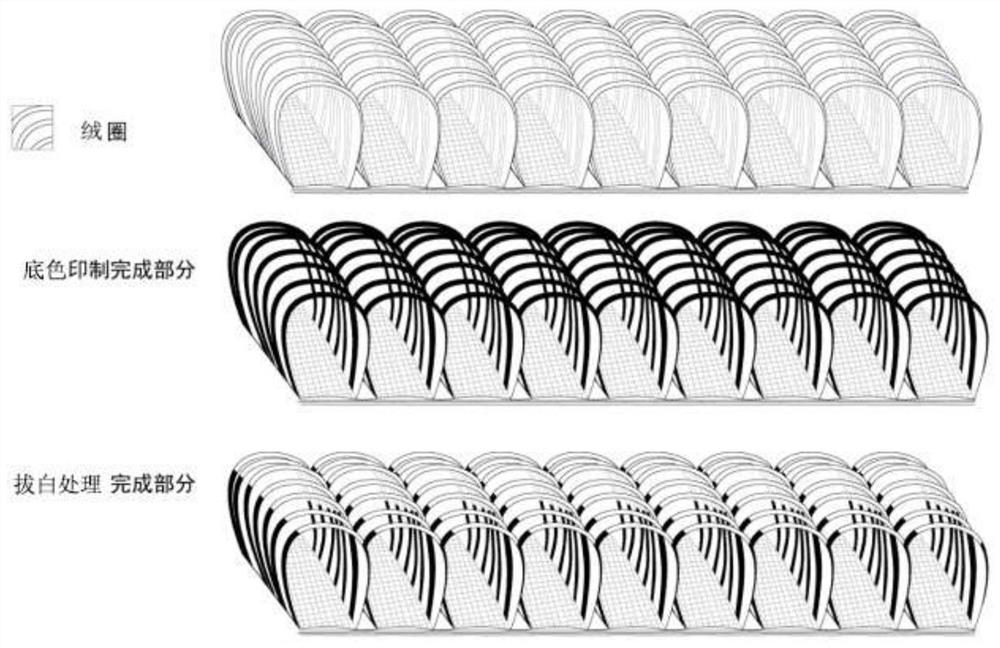

Production method of invisible printed towel

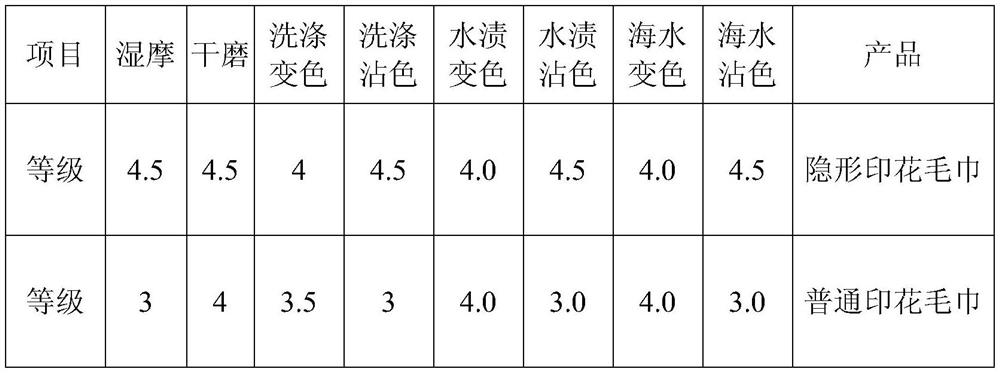

A production method and invisible printing technology, applied in the direction of dyeing, textile and papermaking, household appliances, etc., can solve the problems of monotonous effect, no change, color fastness and white background staining, etc., and achieve a variety of patterns. , comfort experience, washing and rubbing fastness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of production method of stealth printing towel, concrete technological process is as follows:

[0036] Blank towel specification: 76*132.08cm-491.4g pile loop height 10mm;

[0037] Pretreatment of blank towels (scouring and bleaching): the known technology of pure cotton oxygen bleaching, the dynamic water absorption of blank towels can reach 10cm;

[0038] Flower design (can be designed according to different market preferences): large flower type;

[0039] Prepare the screen plate required for background color printing: pattern plate of normal printing color, 60 mesh screen;

[0040] Prepare the screen plate required for white printing: use 120-mesh mesh and design a blanking point with a density of 11%;

[0041] Preparation of base color paste: select reactive dyes as ethylene maple dye orange and monochloro-s-triazine yellow;

[0042] Preparation of whitening pulp: according to mass percentage, raw materials include, solid powder seaweed paste 6%, soda ash...

Embodiment 2

[0047] A kind of production method of stealth printing towel, concrete technological process is as follows:

[0048] Blank towel specification: 34*80cm-90g pile loop height 8mm;

[0049] Pre-treatment (desizing) of blank towels: the known technology of oxygen bleaching of pure cotton, the capillary effect is 10cm;

[0050] Flower pattern design (design according to different market preferences): animal animation pattern pattern;

[0051] Prepare the screen plate required for background color printing: pattern plate of normal printing color, 80 mesh screen;

[0052] Prepare the screen plate required for white printing: use 120-mesh mesh and design a blanking point with a density of 8%;

[0053] Preparation of base color paste: select reactive dyes as phosphonate army blue, bright red, vinyl maple orange;

[0054] Preparation of white pulp: according to mass percentage, raw materials include, solid powder seaweed paste 6%, soda ash 6%, fluorescent whitening agent 1%, insolubl...

Embodiment 3

[0058] A kind of production method of stealth printing towel, concrete technological process is as follows:

[0059] Blank towel specification: 34*35cm-40g pile loop height 8mm;

[0060] Pre-treatment (desizing) of blank towels: the known technology of oxygen bleaching of pure cotton, the capillary effect is 10cm;

[0061]Flower pattern design (design according to different market preferences): animal animation pattern pattern;

[0062] Prepare the screen plate required for background color printing: pattern plate of normal printing color, 80 mesh screen;

[0063] Prepare the screen plate required for white printing: use 200-mesh mesh and design a blanking point with a density of 20%;

[0064] Preparation of base color paste: select reactive dyes as monochloro-s-triazine and vinyl sulfone compound red;

[0065] Preparation of whitening pulp system: according to mass percentage, raw materials include, solid powder seaweed paste 5%, soda ash 6%, fluorescent whitening agent 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com