Bacterial strain for producing biological flocculant and biological flocculant produced by using bacterial strain

A technology of biological flocculants and strains, which is applied in the field of oily sewage treatment, can solve the problems of residual toxicity of secondary pollution, etc., and achieve the effects of residual toxicity, diameter reduction, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

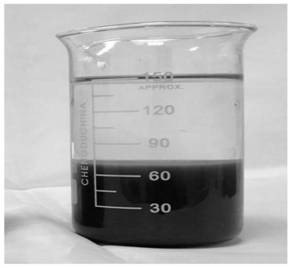

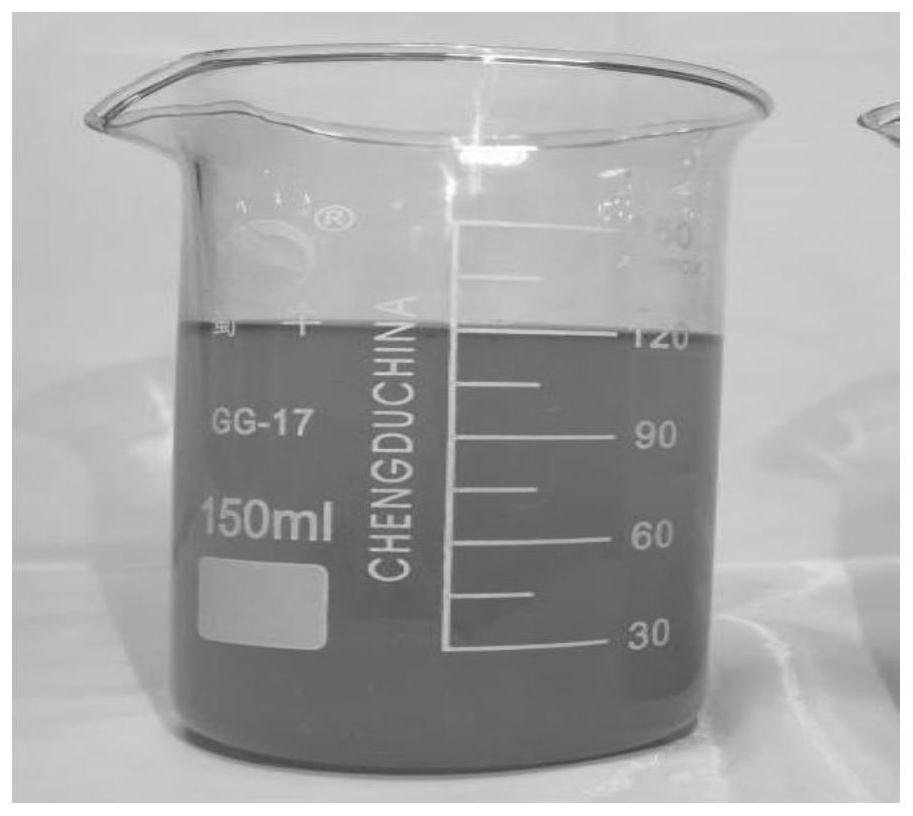

[0036] Such as figure 1 and figure 2 Shown, a kind of method that utilizes biological flocculant as above to treat oily sewage, comprises the following steps:

[0037] S1, such as figure 1 Get 120mL of oily sewage to be treated and add it to the beaker, adjust the pH of the oily sewage to be treated to 6, and obtain the pretreated oily sewage;

[0038] S2, add 15g / L described biological flocculant to the oily sewage after the pretreatment in step S1, then mix uniformly and let stand for 2min, obtain such as figure 2 For the treated oily sewage shown, the mass ratio of the pretreated oily sludge to the biological flocculant is 100:1.

[0039] The oily sewage before and after treatment is detected in the following table 1:

[0040] Table 1 Comparison table before and after treatment of oily sewage with biological flocculants

[0041] index before processing after treatment Drainage water quality standard Suspended solid content, mg / L 207 15.3 ≤30.0...

Embodiment 2

[0045] The difference from Example 1 is that, as image 3 As shown, take 135mL of oily waste water to be treated and add it to the beaker. The oily waste water is scraped on the surface of the drilling trial repair waste liquid to remove oil slicks, and the remaining drilling trial repair waste liquid is oily waste water to be treated. get as Figure 4 The treated oily wastewater is shown.

[0046] The oily sewage before and after treatment is detected in the following table 2:

[0047] Table 2 Comparison table before and after treatment of oily sewage with biological flocculants

[0048] index before processing after treatment Drainage water quality standard Suspended solid content, mg / L 152 10.2 ≤30.0 Median particle diameter of suspended solids, μm 21.3 3.5 ≤5.0 Oil content, mg / L 214 35.4 ≤50.0

[0049] From the above, using the biological flocculant of the present invention to treat oily wastewater according to the method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com