A self-sensing and repairing ball guide shoe for elevators

A self-sensing, ball-bearing technology, applied in the elevator field, can solve the problems of a lot of manpower and material costs, affecting the normal use of the elevator, and reducing the guiding accuracy, achieving the effect of long maintenance cycle, avoiding large-area shedding, and reducing friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

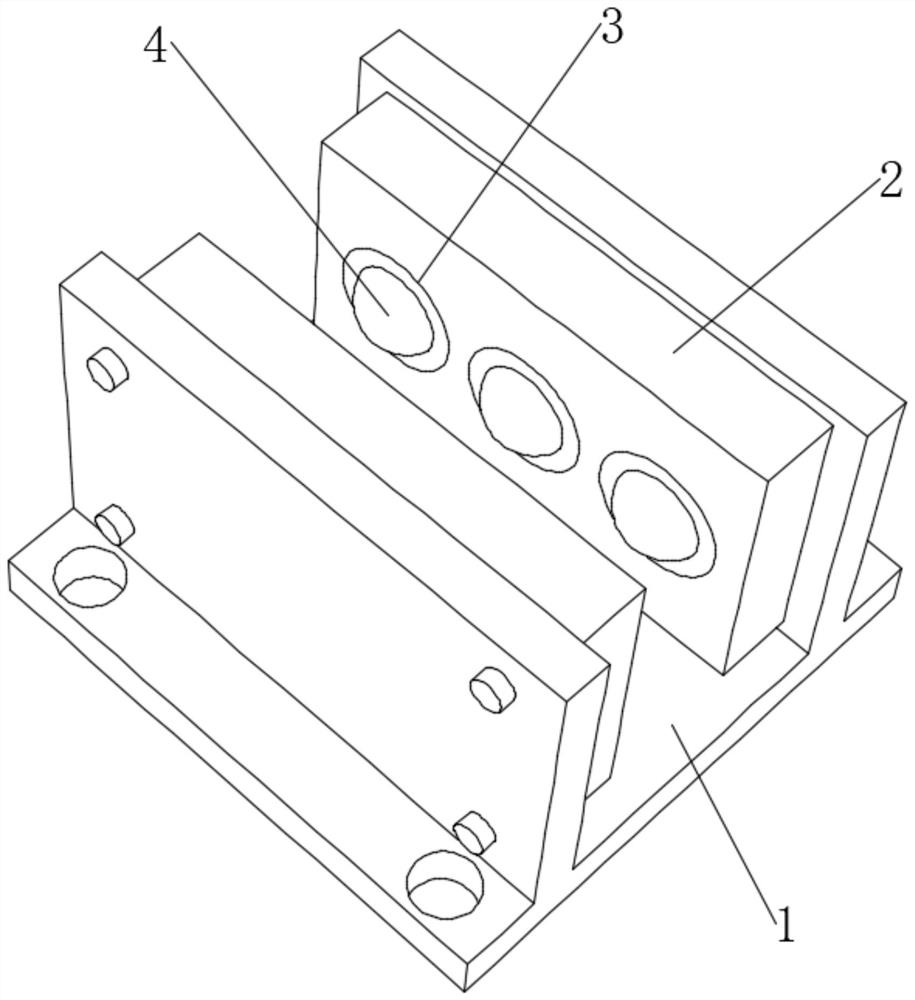

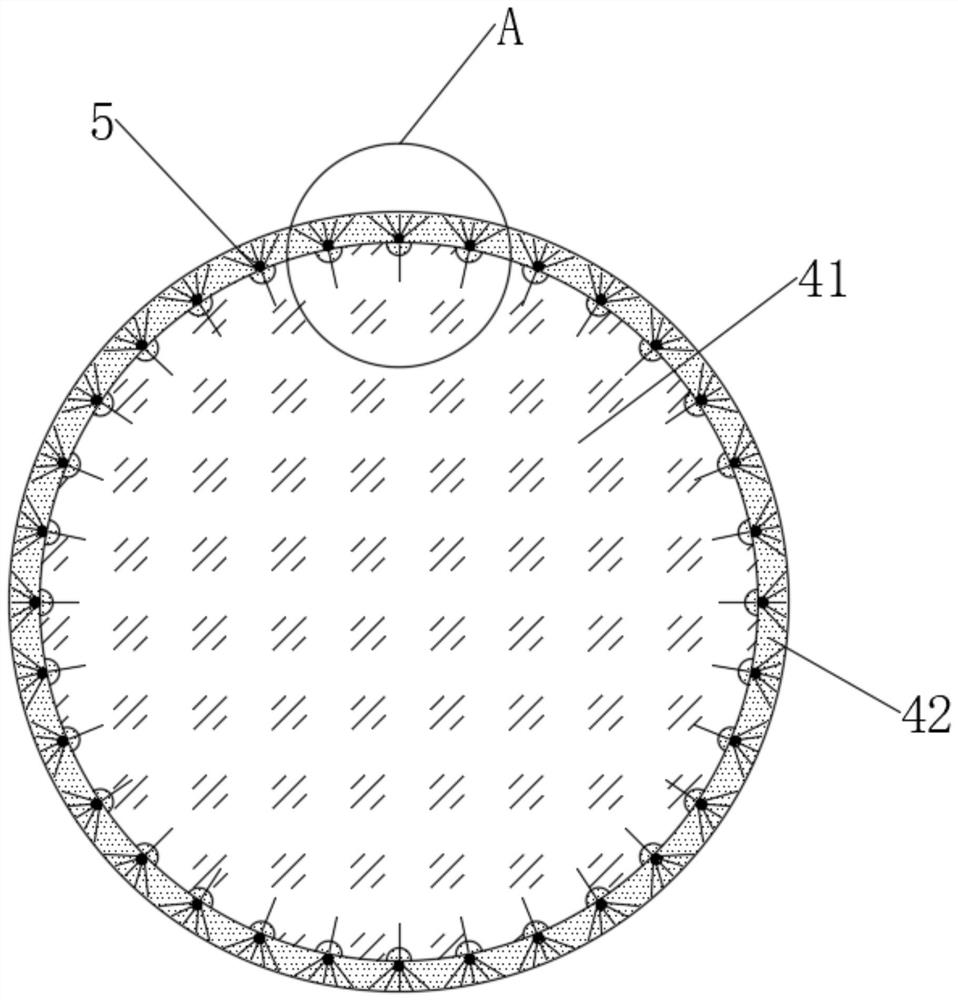

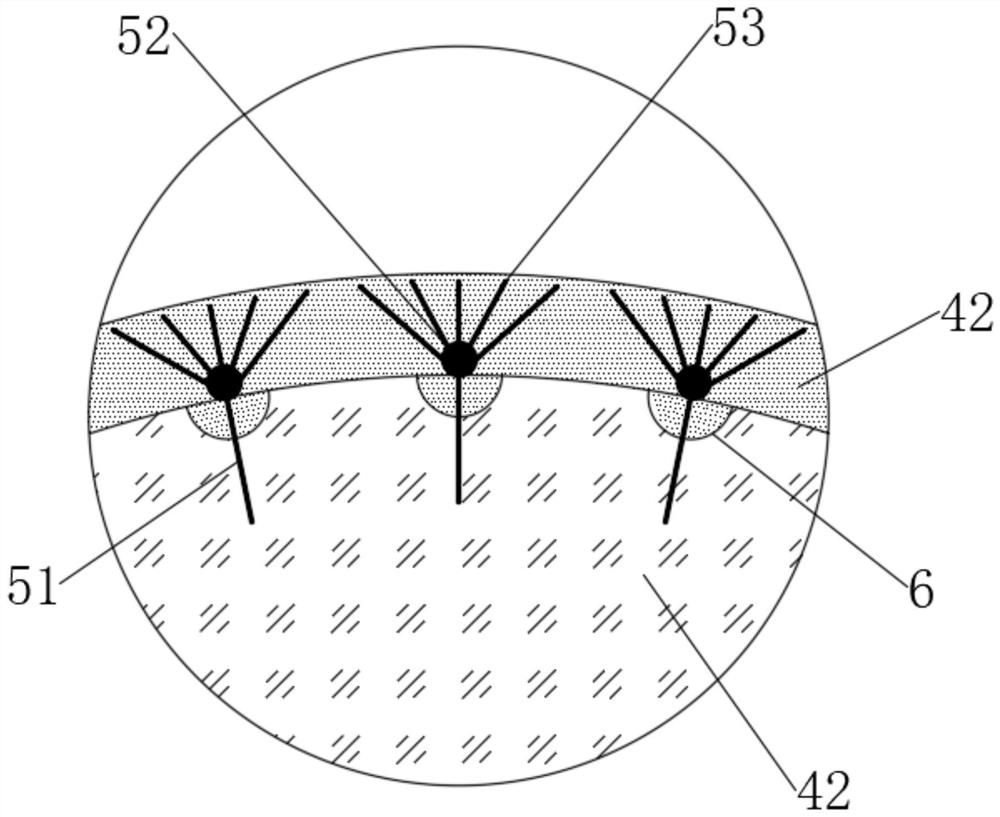

[0043] see Figure 1-2 , a self-sensing repair type ball guide shoe for elevators, including a guide shoe seat 1, a pair of guide wing blocks 2 are fixedly installed on the guide shoe seat 1, and a pair of guide wing blocks 2 are inlaid and connected with a plurality of evenly distributed The repaired ball seat 3, the matching composite high wear-resistant ball 4 is installed in the repaired ball seat 3, please refer to figure 2 , the composite high wear-resistant ball 4 includes a solid steel ball 41 and a self-sensing wear-resistant layer 42 covering the outer surface of the solid steel ball 41 .

[0044] see Figure 4-5 , the repair ball seat 3 includes a ball seat base 31 that matches the composite high wear-resistant ball 4, the ball seat base 31 is inlaid with a hemispherical repair inlay 32, and the hemispherical repair inlay 32 is inlaid and connected with a plurality of evenly distributed repairs Rod 33, the repair rod 33 includes a feeding pipe 331 and a spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com