Automobile front wall inner sound insulation pad and preparation method and application thereof

A technology for sound insulation pads and automobiles, which is applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve the problems of poor sound insulation effect, single structure of front wall sound insulation pads, degumming, etc., and achieve the effect of improving sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

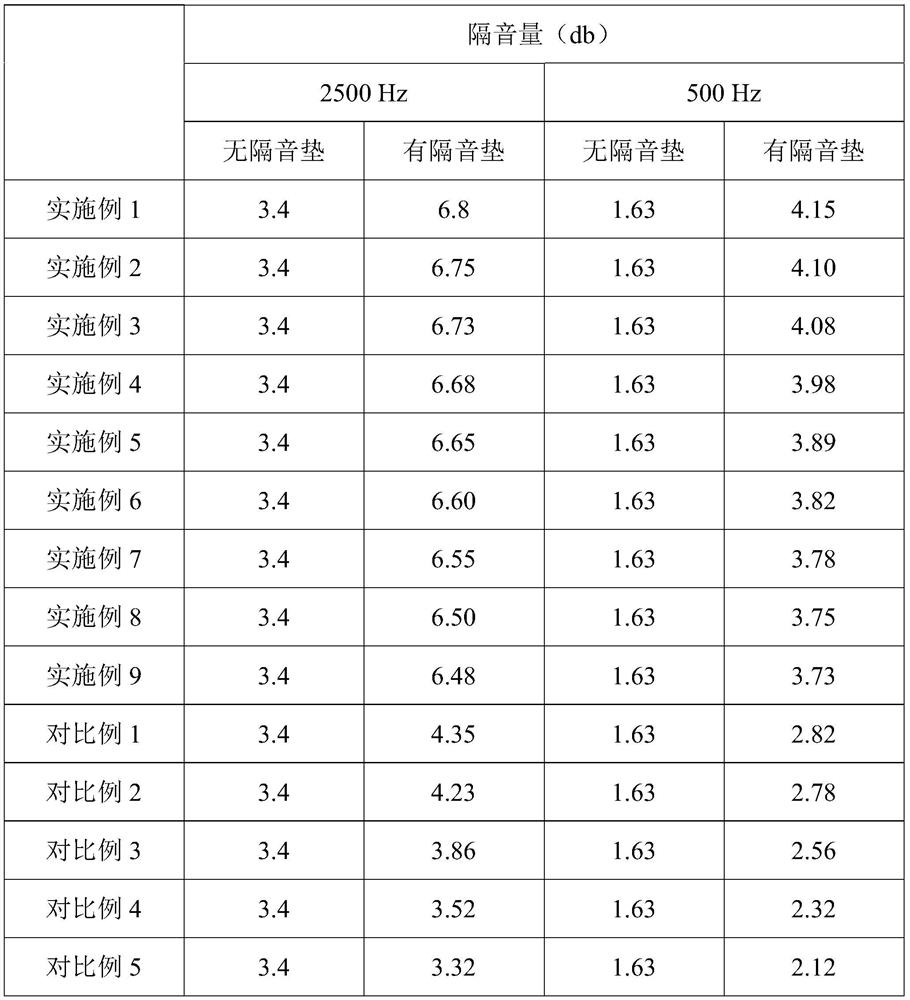

Examples

Embodiment 1

[0104] This embodiment provides a sound-insulating pad in the front wall of an automobile, which includes a sound-insulating cotton layer, a heavy coating layer, a foot pad and a PU foam layer that are stacked in sequence, wherein the material of the sound-insulating cotton layer is thermoplastic back-spun cotton, and the heavy-duty The coating material is EPDM, and the foot pads are EPP foot pads. The parameters of each layer are as follows:

[0105] composition parameter Thermoplastic back spun cotton layer Thickness 13mm EPDM layer Thickness 1.3mm EPP foot pad Thickness 13cm; Density 27kg / m 3

PU foam layer Thickness 17cm

[0106] The preparation method of the sound insulation pad in the front wall of the automobile is as follows:

[0107] (1) Thermoplastic back-spun cotton is placed on the net chain;

[0108] (2) Based on step (1), send the thermoplastic back-spun cotton into the oven for drying; the temperature of the upper o...

Embodiment 2

[0118] This embodiment provides a sound-insulating pad in the front wall of an automobile, which includes a sound-insulating cotton layer, a heavy coating layer, a foot pad and a PU foam layer that are stacked in sequence, wherein the material of the sound-insulating cotton layer is thermoplastic back-spun cotton, and the heavy-duty The coating material is EPDM, and the foot pads are EPP foot pads. The parameters of each layer are as follows:

[0119] composition parameter Thermoplastic back spun cotton layer Thickness 10mm EPDM layer Thickness 1mm EPP foot pad Thickness 10cm; Density 25kg / m 3

PU foam layer Thickness 15cm

[0120] The preparation method of the sound insulation pad in the front wall of the automobile is as follows:

[0121] (1) Thermoplastic back-spun cotton is placed on the net chain;

[0122] (2) Based on step (1), send the thermoplastic back-spun cotton into the oven for drying; the temperature of the upper ove...

Embodiment 3

[0132] This embodiment provides a kind of sound-insulating pad in the front wall of an automobile, comprising a sound-insulating cotton layer, a heavy coating layer, a foot pad and a PU foam layer which are stacked in sequence, wherein the material of the sound-insulating cotton layer is felt, and the heavy-coated layer is made of felt. The material is EVA, and the foot pads are EPP foot pads. The parameters of each layer are as follows:

[0133] composition parameter felt layer Thickness 15mm EVA layer Thickness 1.5mm EPP foot pad Thickness 15cm; Density 30kg / m 3

PU foam layer Thickness 20cm

[0134] The preparation method of the sound insulation pad in the front wall of the automobile is as follows:

[0135] (1) Place the felt on the net chain;

[0136] (2) Based on step (1), send the felt into the oven for drying; the temperature of the upper oven is set at 350°C, the temperature of the lower oven is set at 350°C, and the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com