Toner cartridge gear and transmission structure thereof

A technology of gear transmission and toner cartridge, applied in the field of toner cartridge gear and its transmission structure, can solve the problems of disengagement of the twisting head, high output cost, high precision of processing and assembly, and achieve smooth installation and removal, practicality Strong, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

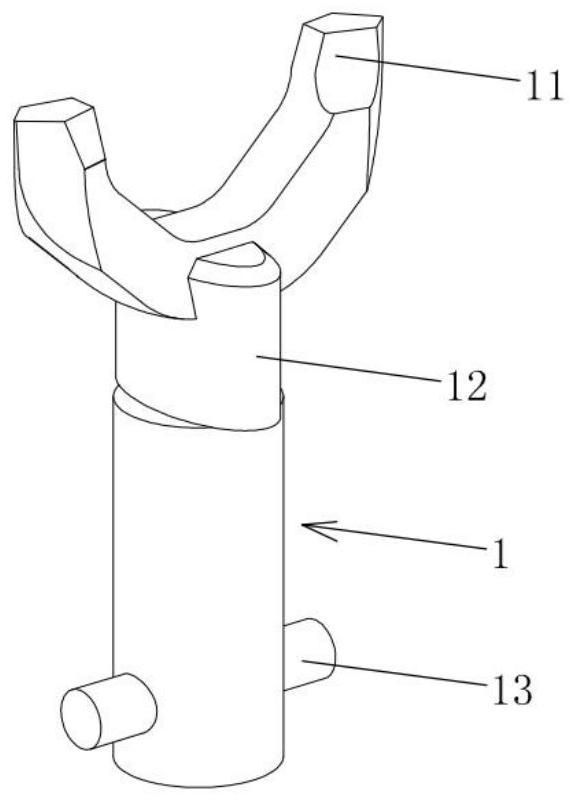

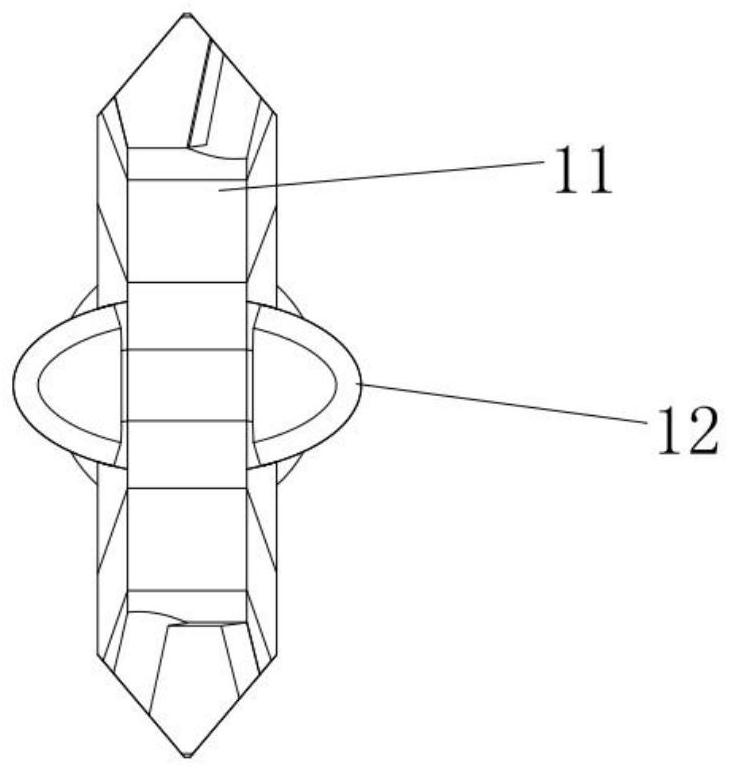

[0030] Embodiment 1: The coupling arm and the transmission part are assembled. The gear 2 is provided with a central shaft hole 20 for the transmission member 1 to extend out of the gear 2 . When installing, firstly, the lower part of the transmission part 1 passes through the central shaft hole 20 on the gear 2 and extends from the top of the groove cavity 21, and the lower part of the transmission part 1 passes through the groove cavity 21 and can protrude from the opening 22 at the bottom of the groove cavity 21. Cavity 21 outside. The coupler arm 13 is designed to slide axially into the rod-like structure inside the slot cavity 21 through the opening 23 at the bottom of the slot cavity 21 , and a plurality of openings 23 for the pair of coupler arms 13 to pass through are arranged along the outer circumference of the opening 22 . The inner end of the coupler arm 13 can be snap-connected with the clamping hole at the lower part of the transmission member 1 and then axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com