Test system and test method for simulating transformer fire combustion under electric field condition

A technology for simulating transformers and testing systems, applied in the direction of using combustion for chemical analysis, etc., can solve problems such as unpredictable control measures, and achieve the effects of reducing fire occurrence, simple operation, and personal protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] see figure 1 , The test system for simulating transformer fire combustion under electric field conditions in this embodiment includes: tester 1, proportional mixer 3, gas tank group, ignition energy generator 5 and transformer oil constant temperature heating device 2. The inner cavity of the tester 1 is connected to the transformer oil constant temperature heating device 2 through the oil inlet pipeline 21 and the oil outlet pipeline 22 to connect to the circulating oil circuit; Connected, the output end of the proportional mixer 3 communicates with the inner cavity of the tester 1 so that the combustible gases from multiple gas tanks are mixed in proportion and then input into the tester 1; the ignition end of the ignition energy generator 5 is connected to the tester 1 Cavity, providing ignition arc for tester 1.

[0036] The above-mentioned structure can simulate the working state and initial oil temperature of the transformer oil in the inner cavity of the tester ...

Embodiment 2

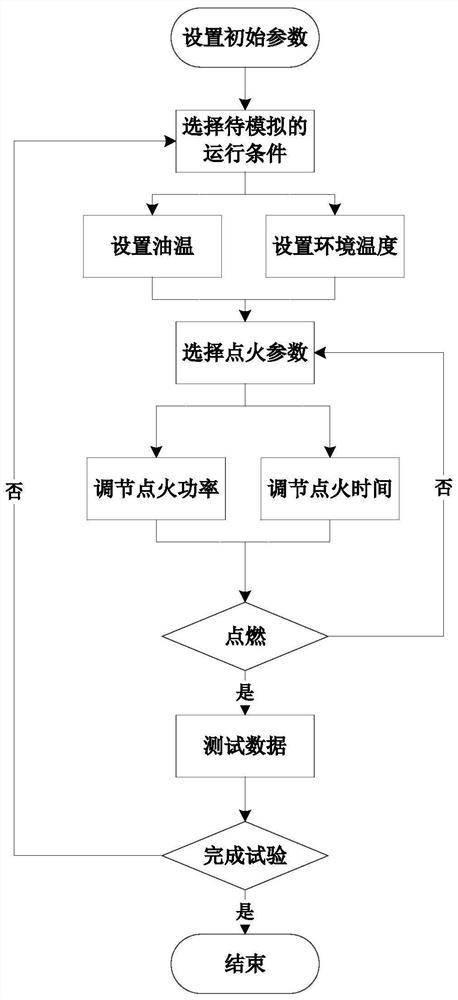

[0039] This embodiment is a test method for simulating transformer fire combustion under electric field conditions using the test system of Embodiment 1. This embodiment is used to carry out transformer oil fire ignition mechanism tests at different temperatures, including the following steps:

[0040] S1: adjust the heating oil temperature of the transformer oil constant temperature heating device 2 through the control module 6 to adjust the initial oil temperature;

[0041] S2: adjusting the temperature in the cavity of the tester 1 to simulate different ambient temperatures;

[0042] S3: Adjust the ignition power and ignition duration of the ignition energy generator 5 to adjust the ignition energy. After the oil temperature and ambient temperature reach the set value and stabilize, start the energy generator to ignite; repeat the steps of adjusting the ignition energy and ignition until the test The critical ignition energy of transformer oil at a specified initial oil tem...

Embodiment 3

[0046] The method adopted in this embodiment is basically the same as that in Embodiment 2. This embodiment simulates a 220kV transformer oil fire ignition test. The transformer oil operates at 85°C and the internal air temperature is 90°C. Tester 1 has a constant temperature range of 0-200°C and a pressure range of 0-200kPa. The ignition mode of the ignition energy generator 5 is pulse ignition, the spark energy range is 0.1-2000mJ, and the ignition voltage is 15kV.

[0047] see figure 2 , the test process is as follows:

[0048] S1: Build a test platform according to the instructions, and prepare test consumables such as transformer oil.

[0049] S2: Initialize the instrument and equipment, set the heating temperature of the transformer oil constant temperature heating device 2 to 85°C, and set the internal air temperature of the tester 1 to 90°C.

[0050] S3: Set the ignition energy of the electric spark to 5mJ, and the ignition time to 10ms.

[0051] S4: When the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com