Novel fused salt heat absorber

A heat absorber and molten salt technology, applied in solar collectors, fluid circuit connection of solar collectors, solar heat storage, etc., can solve the problem of lack of analysis of the temperature drop characteristics of heat absorbers, and achieve compact structure , Improve the absorption rate and slow down the effect of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

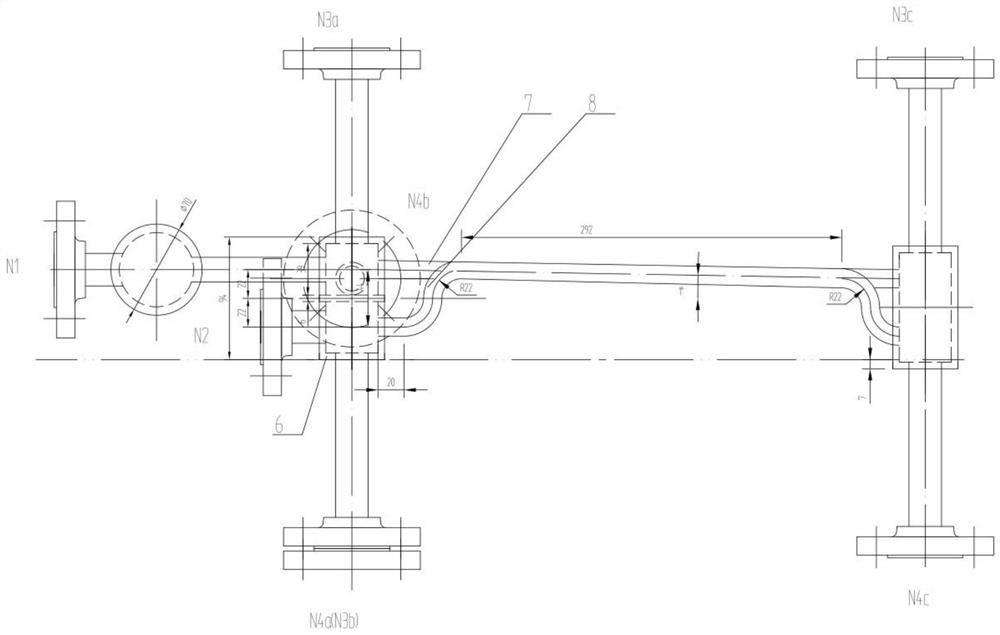

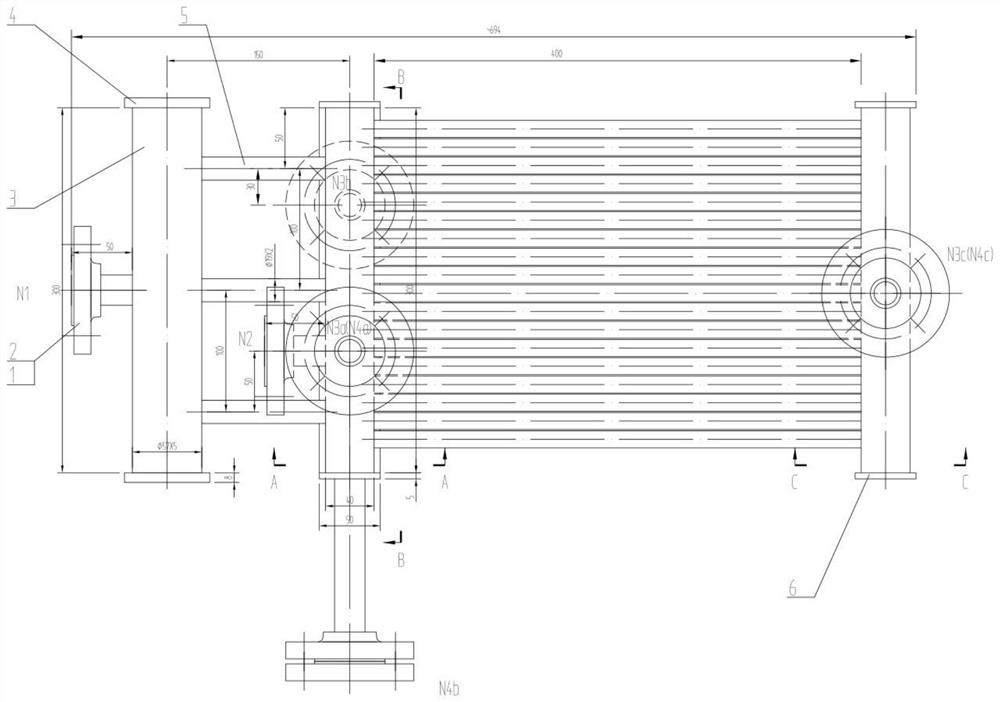

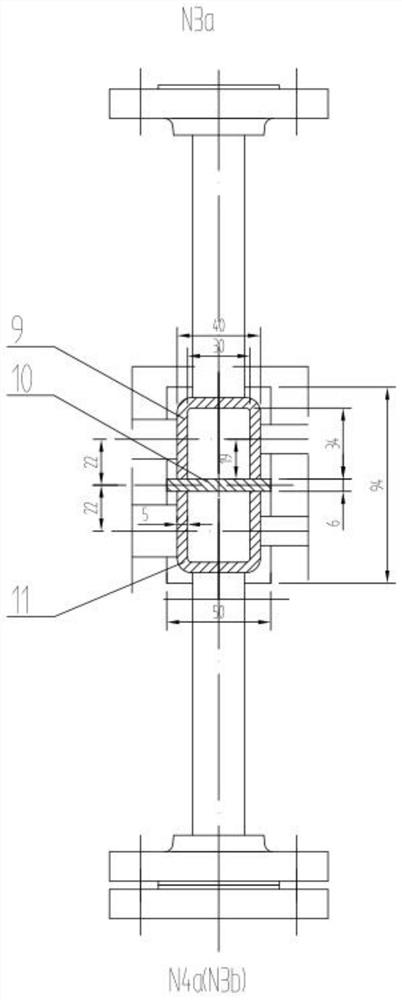

[0021] The invention provides a novel molten salt heat absorber, see Figure 1-5 , including: distribution header 3, connecting pipe 5, heat absorption pipe, inlet header 9, outlet header 11, intermediate header 12;

[0022] The distribution header 3 is connected to the inlet header 9 through the communication pipe 5; the inlet header 9 and the outlet header 11 are of an integrated structure, separated by a partition 10 in the middle; the inlet header The box 9 is connected with the middle header 12 through the upper row of heat-absorbing pipes 7; the intermediate header 12 is connected with the outlet header 11 through the lower row of heat-absorbing pipes 8; the heat-absorbing pipe includes The upper row of heat absorbing pipes 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com