Novel non-combustible floor heating system

A new type of floor heating technology, applied in the field of floor heating, can solve problems such as uneven heating of heating cables, low temperature of heating cables, and potential fire safety hazards, and achieve the effects of eliminating potential safety hazards, reducing heating efficiency, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

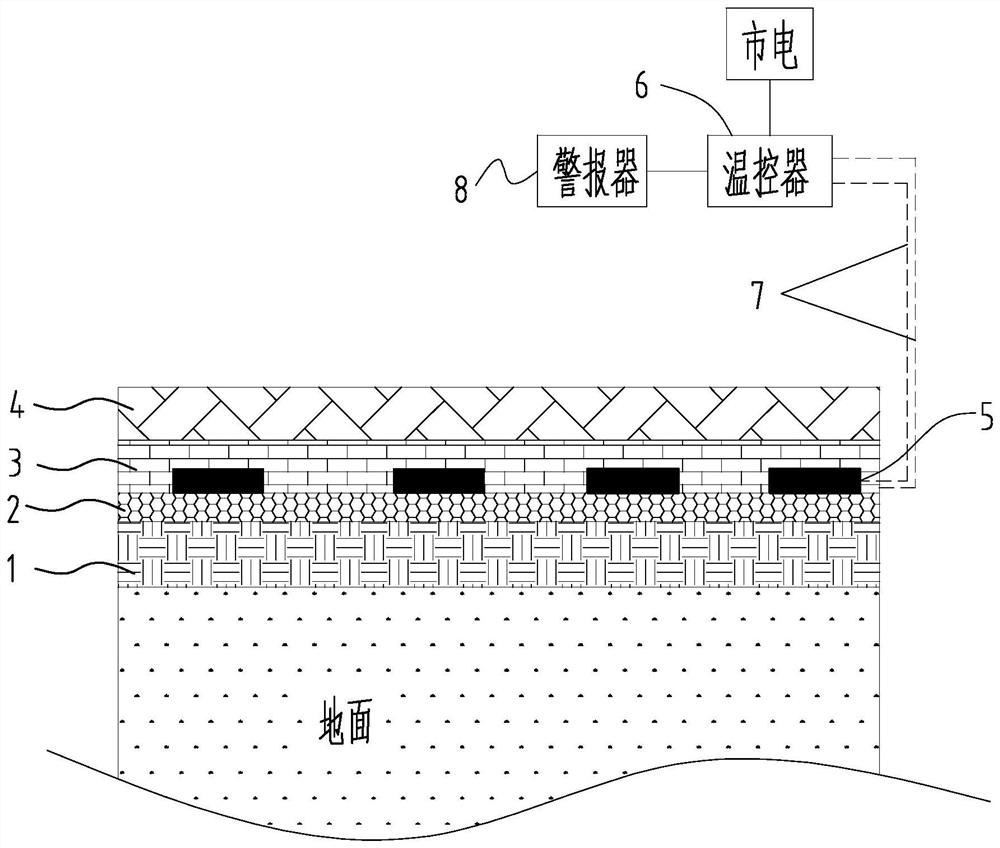

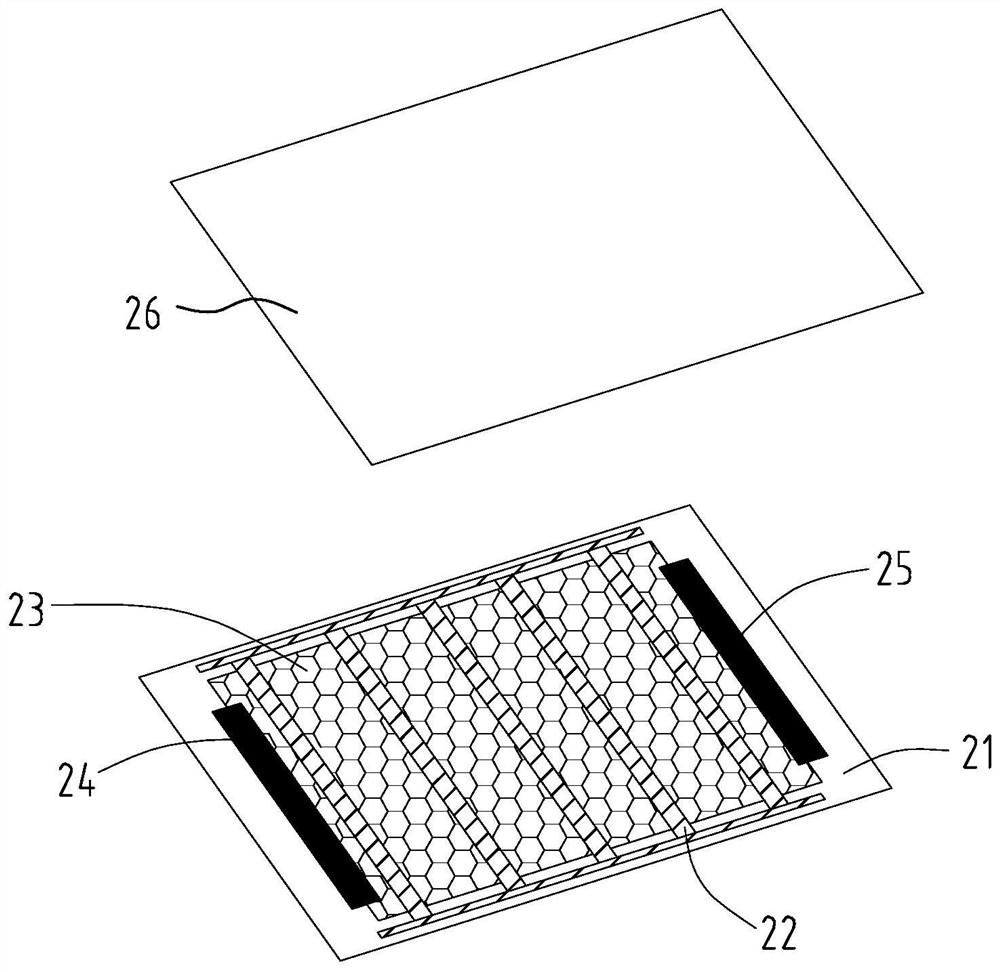

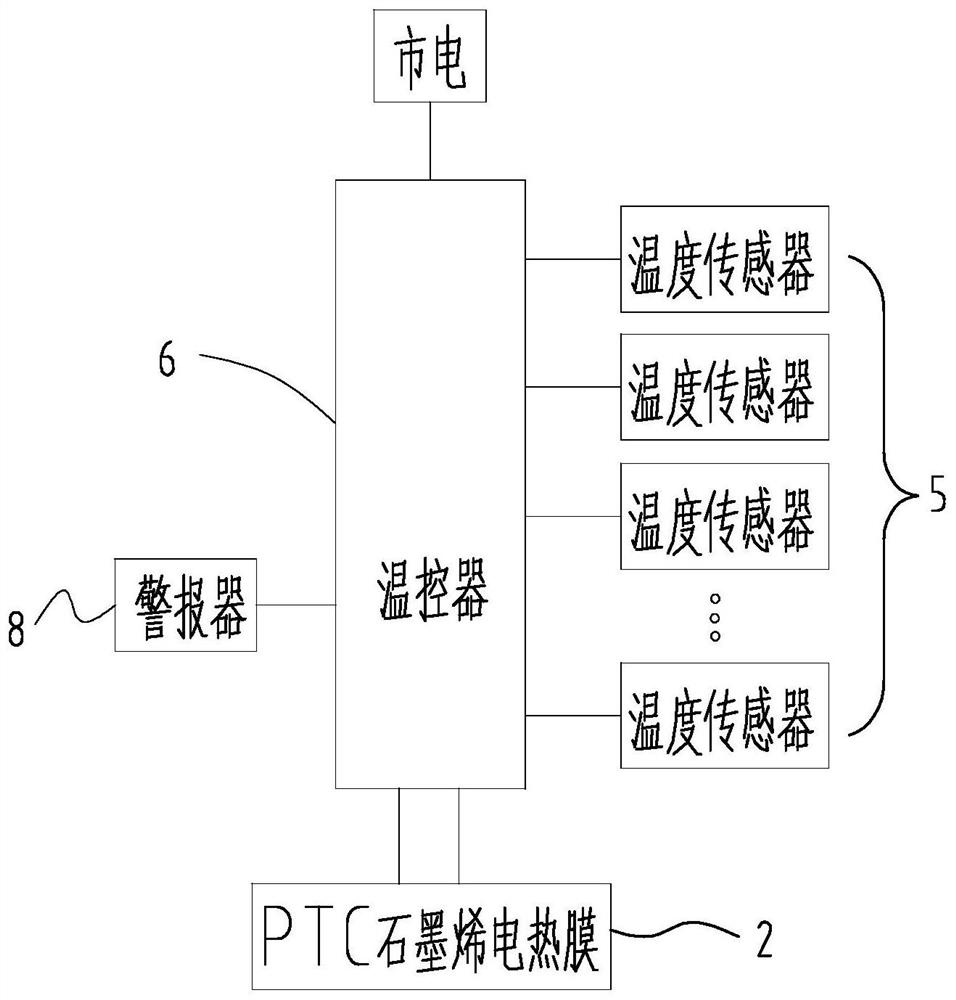

[0017] refer to figure 1 , figure 2 and image 3 , this embodiment provides a new type of non-combustible floor heating system, including a thermostat 6, a plurality of temperature sensors 5 ( figure 1 Only four temperature sensors 5), alarm 8, and flame-retardant insulation layer 1, PTC graphene electrothermal film 2, thermally conductive flame-retardant cement mortar layer 3 and ground decoration layer are arranged on the ground sequentially from bottom to top. 4. A flame-retardant cable 7 is also buried between the flame-retardant insulation layer 1 and the thermally conductive flame-retardant cement mortar layer 3, and the temperature sensors 5 are evenly and equally spaced between the PTC graphene electrothermal film 2 and the thermally conductive Between fire-retardant cement mortar layers 3. In this specific embodiment, the flame retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com