Automatic precision pressure regulating valve

A precision pressure regulating valve and pressure regulating valve technology, applied in valve details, valve devices, engine components, etc., can solve the problems of slow adjustment speed, wrong value touch, and difficult value control, etc., to achieve adjustment speed block, data control, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

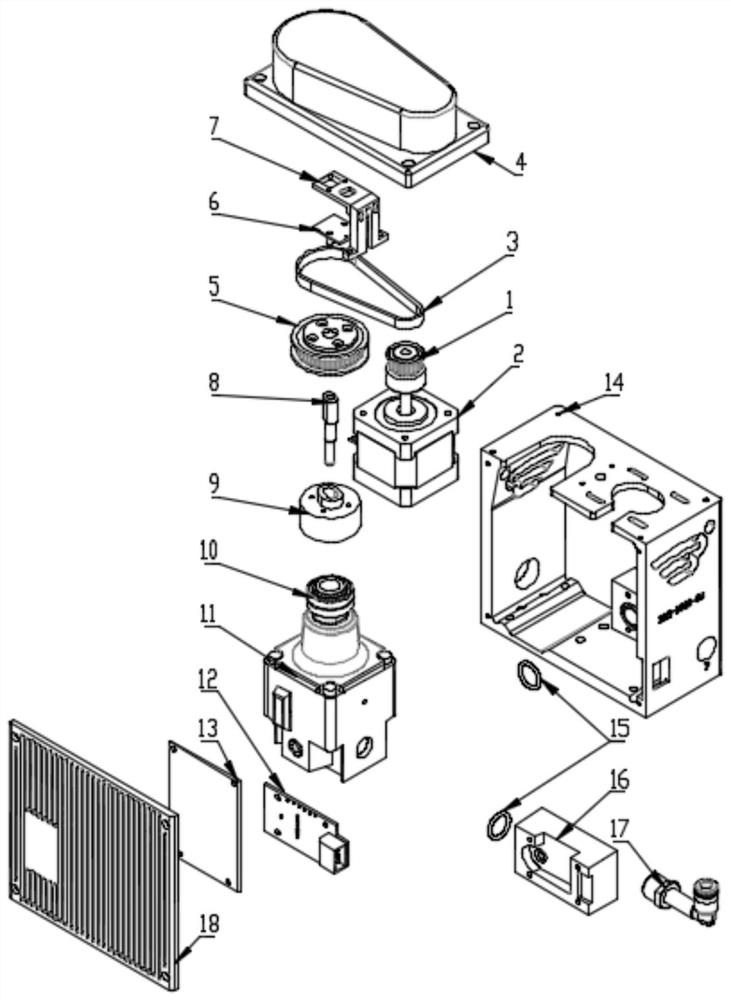

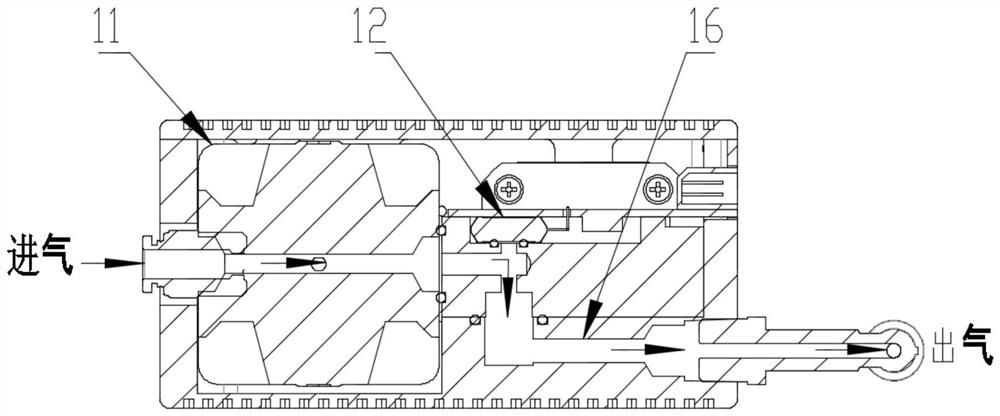

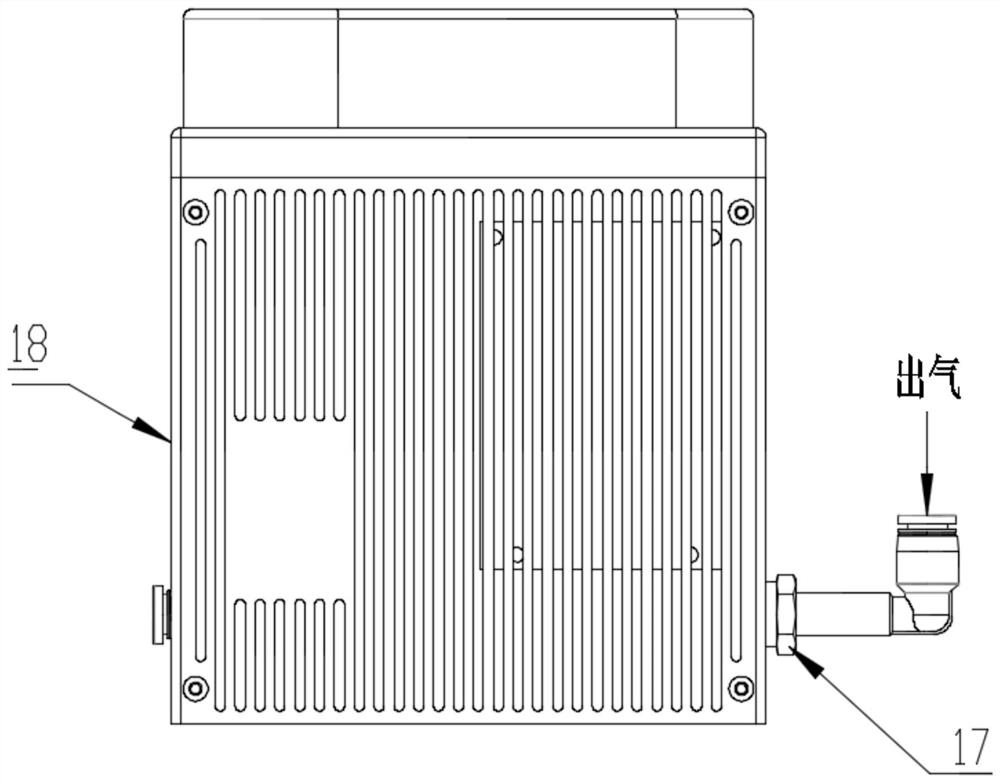

[0024] refer to Figure 1-3 , an automatic precision pressure regulating valve, including a base 14, a stepper motor 2 is fixed on one side of the inner wall of the base 14 by bolts, the top of the output shaft of the stepper motor 2 is fixed with a synchronous wheel a1 by screws, and the outer wall of the synchronous wheel a1 is sleeved with Synchronous belt 3, the inner wall of one side of the synchronous belt 3 is sleeved with a synchronous wheel b5, the inner wall of the synchronous wheel b5 is connected with an adjusting screw 8 through threads, and the inner wall of the bottom of the base 14 is fixed with a pressure regulating valve 11 by bolts, the pressure regulating valve 11 A bearing 10 is sleeved on the top end, and a pressure detection mechanism is provided on one side of the bottom outer wall of the base 14 .

[0025] In the present invention, the top outer wall of the pressure regulating valve 11 is fixed with a fixing seat 9 by screws.

[0026] In the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com