A Transient Detonation Pulse Engine and Radial Multipulse Thrust Vectoring Device

An engine and detonation technology, applied in the field of high-speed rotating aircraft, can solve the problems affecting the landing accuracy of the flying body and the low control accuracy of the radial attitude of the flying rotating body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

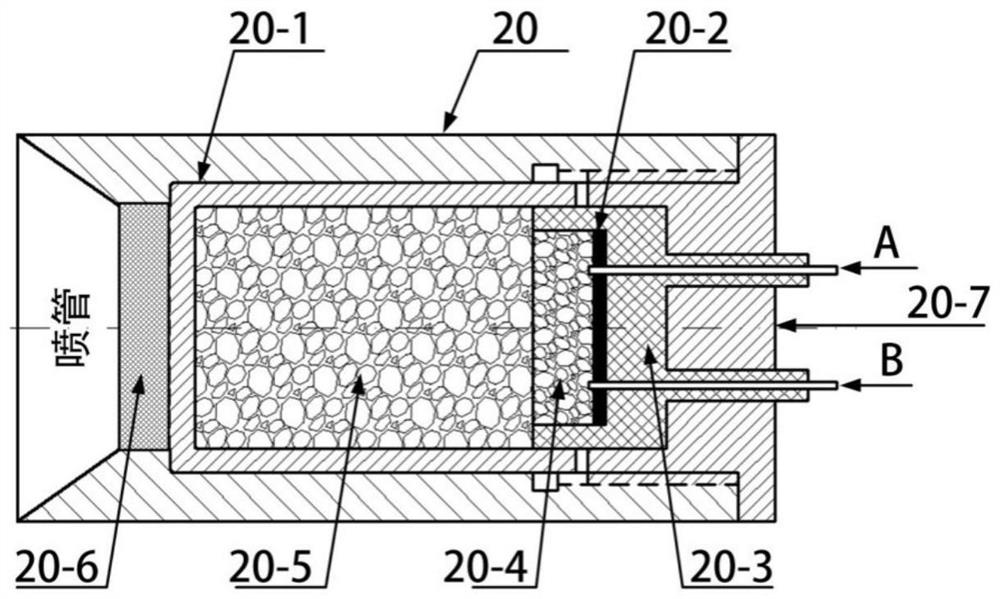

[0020] Such as figure 2 Shown, a kind of transient detonation pulse engine of the present invention is made of engine body 20, reinforcing sleeve 20-1, plasma ignition tool 20-2, insulator 20-3, mixed ignition powder 20-4, strong explosive 20-5 , The spout sealing body 20-6, the head body 20-7, the electrode A, and the electrode B are composed.

[0021] A reinforcement sleeve 20-1 is installed in the engine body 20, and a strong explosive 20-5 is filled in the reinforcement sleeve 20-1; a plasma igniter 20-2, a mixed ignition powder 20-4, and a plasma ignition device are installed in the insulator 20-3. The tool 20-2 is connected with electrode A and electrode B.

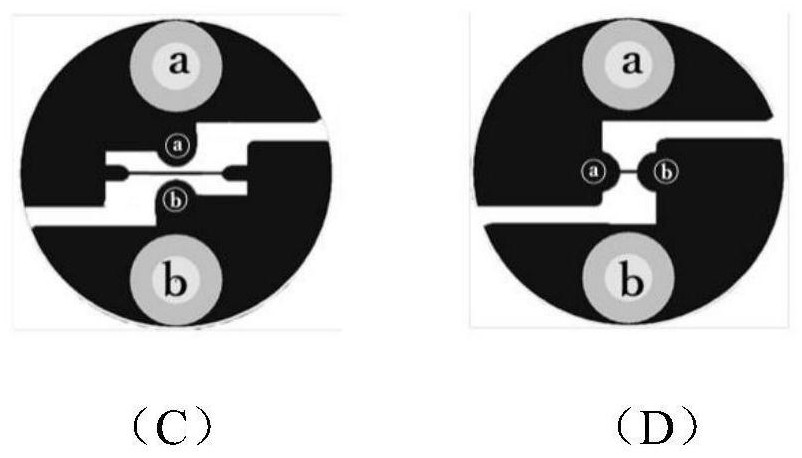

[0022] The plasma igniter 20-2 and the mixed ignition powder 20-4 constitute a micron-scale bridge foil energy-containing plasma igniter device; the plasma igniter 20-2 adopts a vacuum sputtering metal coating process or adopts Ion ignition devices made by printed circuit board technology, see image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com