Automatic dosing control system

A control system and automatic dosing technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems affecting the proportion of drug ingredients and drug quality, and can not guarantee the accuracy of drug dosage, so as to solve the cumbersome and Inconvenience, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

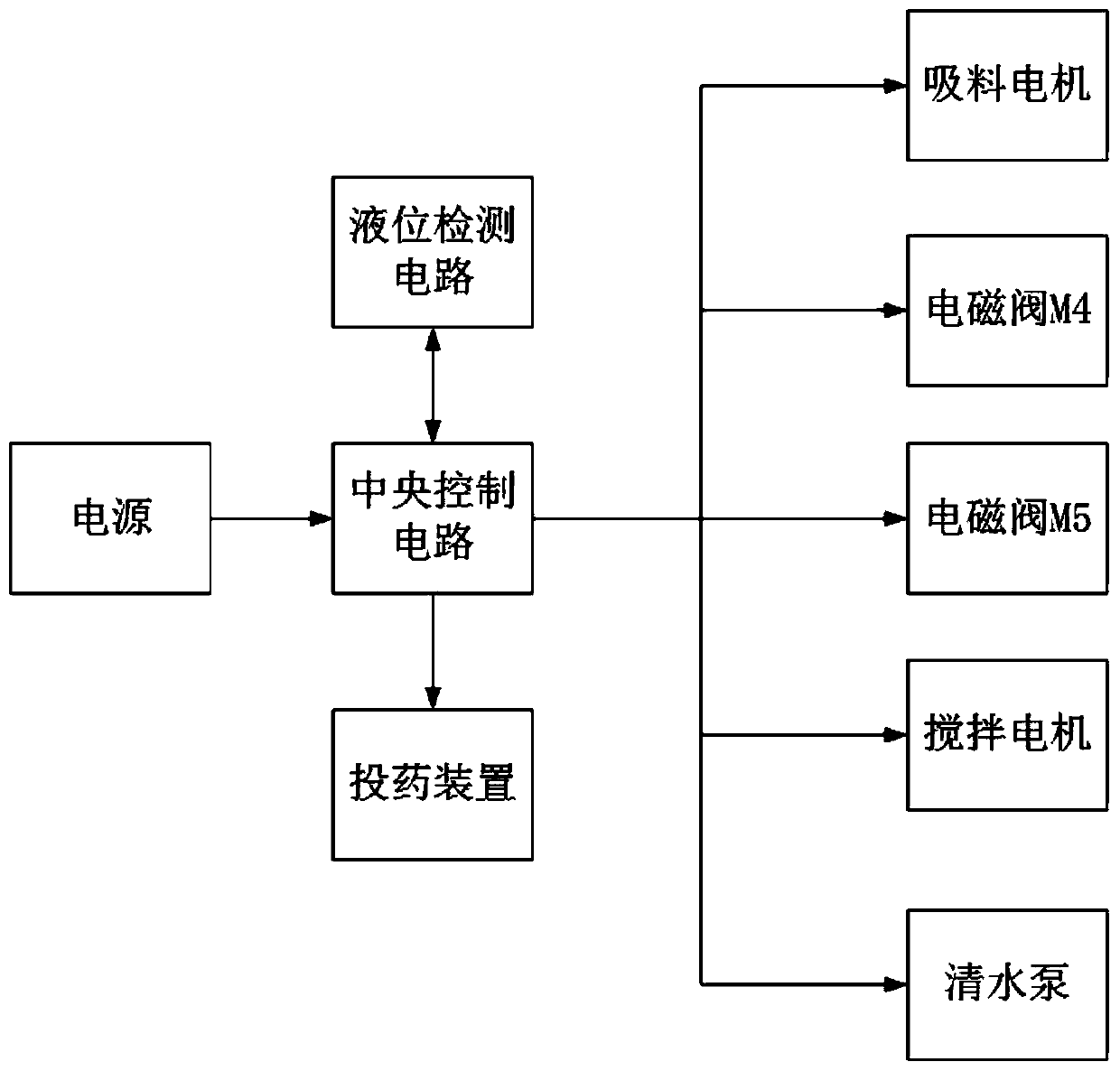

[0024] An automatic dosing control system, characterized in that it includes a power supply, a liquid level detection circuit, a central control circuit, a solenoid valve M4, a solenoid valve M5, a clean water pump M1, a stirring motor M2, and a material suction motor M6. Circuit connection, the input interface of the central control circuit is connected with the liquid level detection circuit, and the output interface of the central control circuit is respectively connected with the solenoid valve M4, the solenoid valve M5, the clean water pump M1, the stirring motor M2, and the suction motor M6.

[0025] The power supply is a three-phase four-wire power supply with a rated voltage / frequency of 380V / 50Hz. The control voltage for the solenoid valve M4, solenoid valve M5, stirring motor M2, suction motor M6, and clean water pump M1 is 220V.

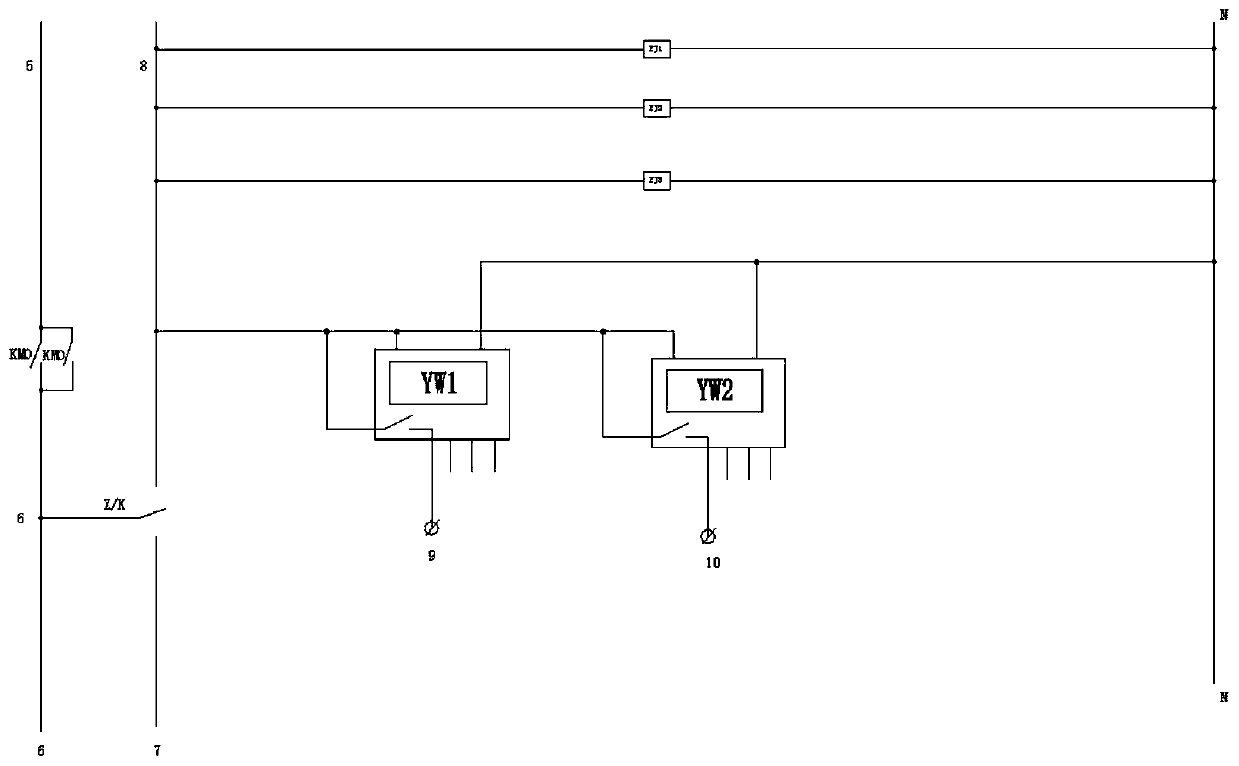

[0026] The liquid level detection circuit includes a liquid level relay YW1, a liquid level relay YW2, and three intermediate relays ZJ1~Z...

Embodiment 2

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 The automatic dosing control system shown is characterized in that it includes a power supply, a liquid level detection circuit, a central control circuit, a solenoid valve M4, a solenoid valve M5, a clean water pump M1, a stirring motor M2, and a material suction motor M6. It is connected with each circuit, the input interface of the central control circuit is connected with the liquid level detection circuit, and the output interface of the central control circuit is respectively connected with the solenoid valve M4, the solenoid valve M5, the clean water pump M1, the stirring motor M2, and the suction motor M6.

[0040] This embodiment can be divided into two modes of adding medicine, manual and automatic.

[0041] The power supply is a three-phase four-wire power supply with a rated voltage / frequency of 380V / 50Hz and a control voltage of 220V for solenoid valve 1, solenoid valve 2, stirring motor, suction motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com