Super-large-inclination-angle material lifting conveying equipment

A technology for conveying equipment and materials, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effect of reducing land use area, reducing transfer nodes, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

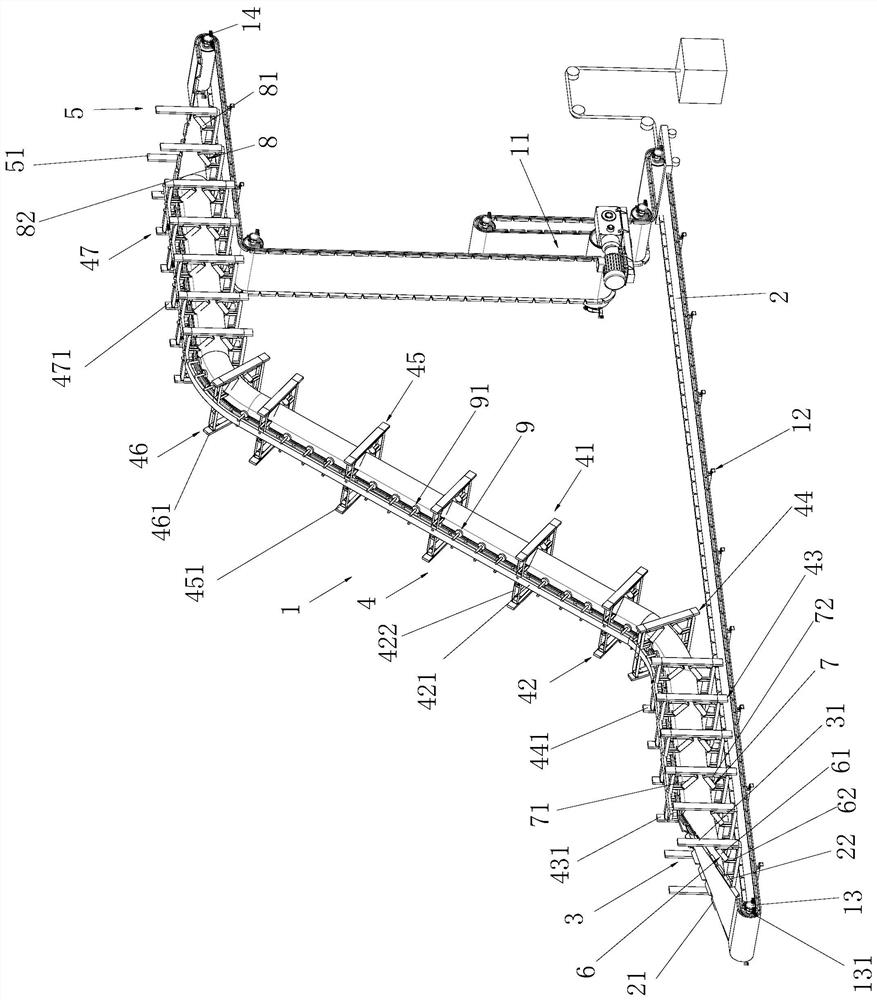

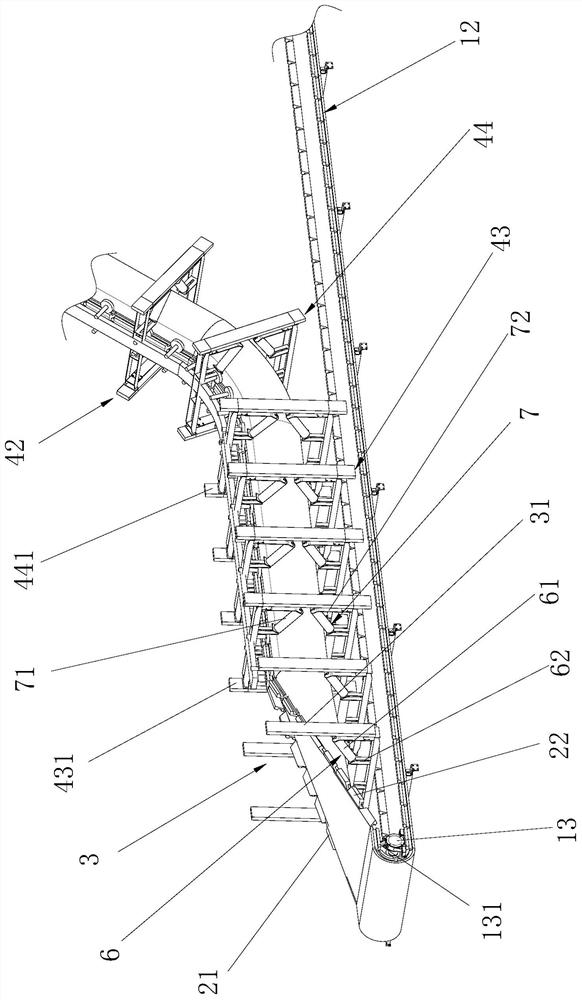

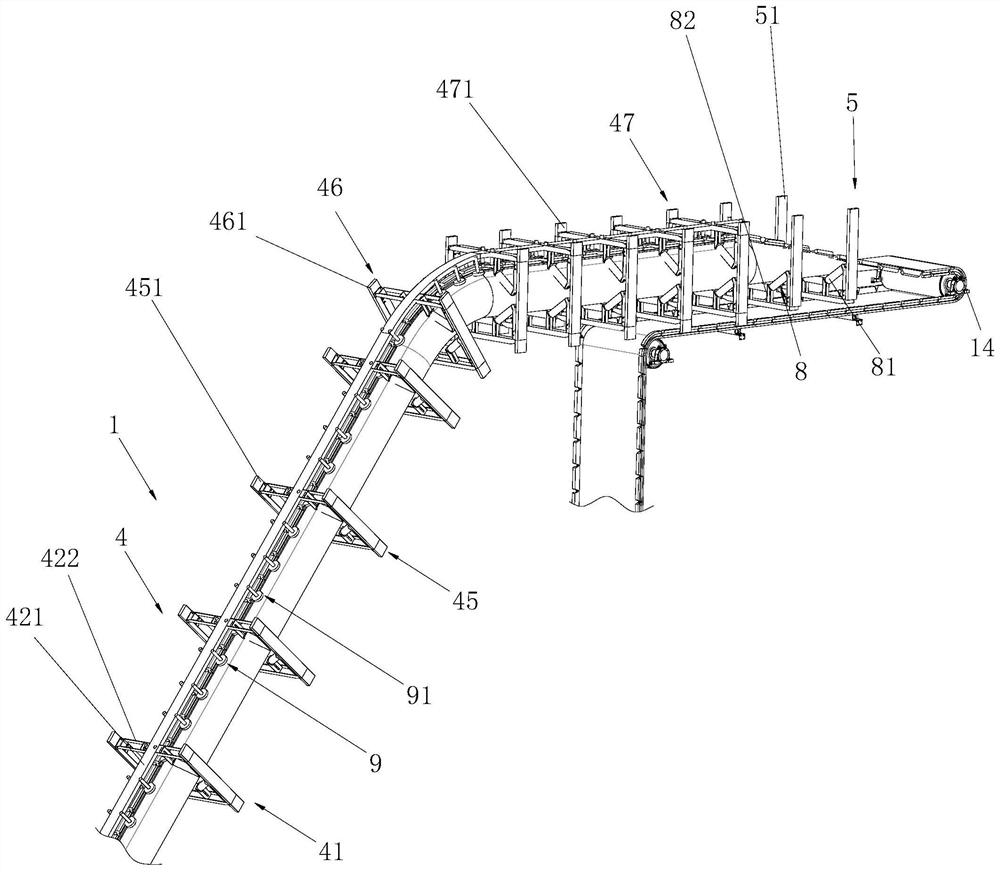

[0041] combine Figure 1 to Figure 8 , a super-inclination material lifting and conveying equipment includes a conveyor, and the conveyor includes a conveyor frame 1 and a conveyor belt 2. Described conveyer frame 1 comprises lower loading part 3, middle lifting part 4 and upper unloading part 5, is respectively provided with in the lower loading part 3, in middle lifting part 4 and upper unloading part 5 and is used for supporting the second conveyor belt 2. A transitional closing mechanism 6, a second lifting and holding mechanism 7, and a third transitional loosening mechanism 8.

[0042] Both sides of the conveyor belt 2 are connected with multiple sets of first ear block assemblies, the first ear block assembly includes a first left ear block 21 and a first right ear block 22; As for the wheel mechanism 9 , each set of first pressing wheel mechanisms 9 includes two first pressing wheel assemblies 91 .

[0043] After the conveyor belt 2 is guided into a closed circular b...

Embodiment 2

[0057] In the above-mentioned material lifting device, according to the material conveying process, the material is firstly loaded onto the conveyor belt at the loading section, where the first buffer roller is installed under the conveyor belt to buffer the impact of the material on the equipment.

[0058] Next, when the conveyor belt passes through the closed transition section, that is, the tightening stage of the first transitional closed mechanism 6 , in actual use, there are three groups of the first transitional closed mechanism 6 . The first transitional closing mechanism 6 in the three groups keeps the conveyer belts away, and the grooving angles of the three groups of supporting rollers are continuously increased, and finally they are closed into circular tubes.

[0059] When the conveyor belt reaches the first transitional closed section of the middle lifting part, the ear block grooves on both sides of the conveyor belt are closed together by the pressure roller so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com