Belt conveyor for boiler fire coal conveying

A belt conveyor, coal burning technology, applied in the direction of conveyor, combustion method, fuel supply, etc., can solve the problems of reducing coal burning efficiency, waste, coal scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

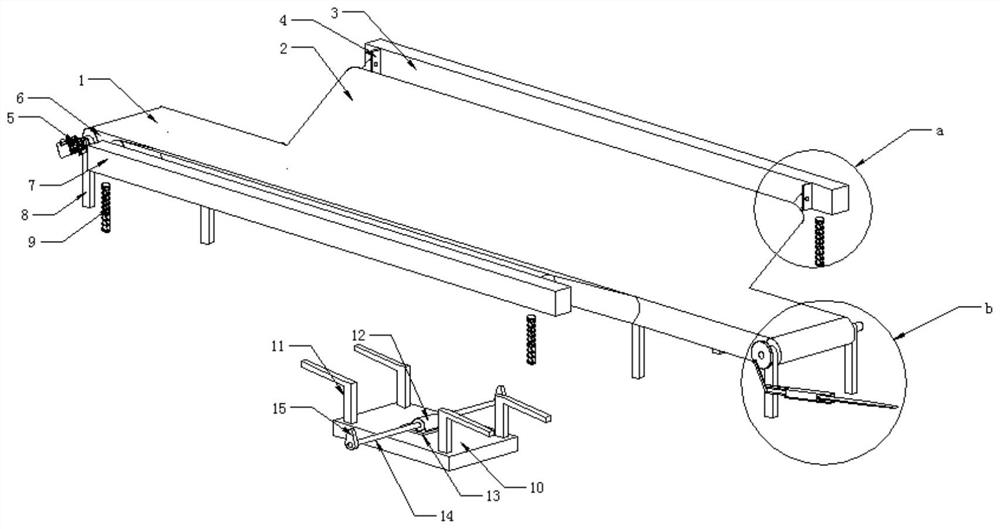

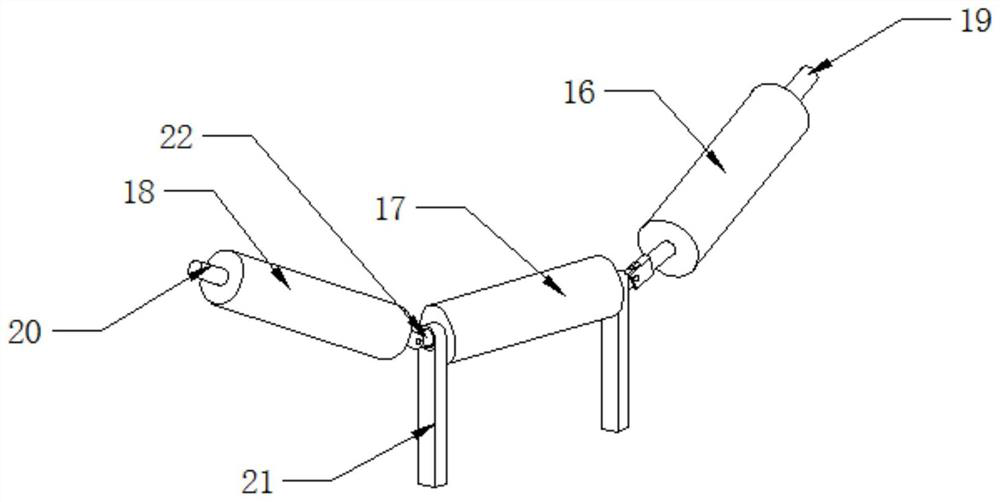

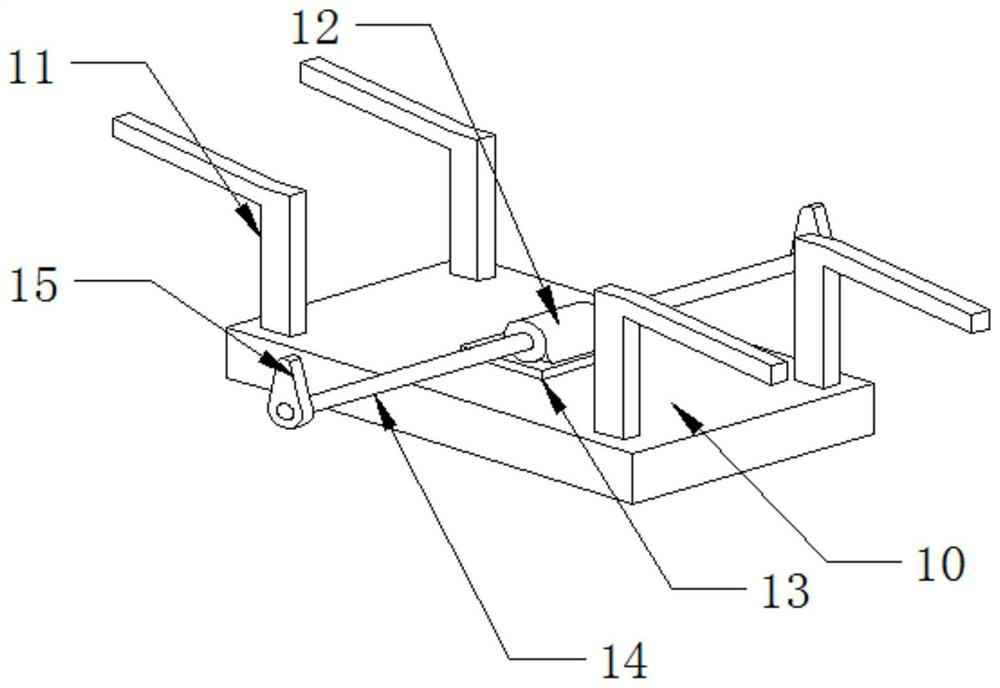

[0025] like Figure 1-Figure 5 As shown, a belt conveyor for boiler coal-fired transportation provided in this embodiment includes a second support leg 21 and a first horizontal driven roller assembly installed at the inner top of the second support leg 21. One end of the driven roller assembly is hinged with a first side driven roller assembly, the other end of the first horizontal driven roller assembly is hinged with a second side driven roller assembly, and the inner middle part of the second support leg 21 is installed through the connecting arm 11 There is a base 10, a vibration drive assembly is installed in the middle of the inner side of the base 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com