Optical fiber movable connector of a crimping-free structure

A flexible connector, crimp-free technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of increasing labor cost and equipment cost, unable to further improve assembly efficiency, assembly failure rate, etc., so as to reduce assembly failure rate. , Reduce the probability of safety accidents and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

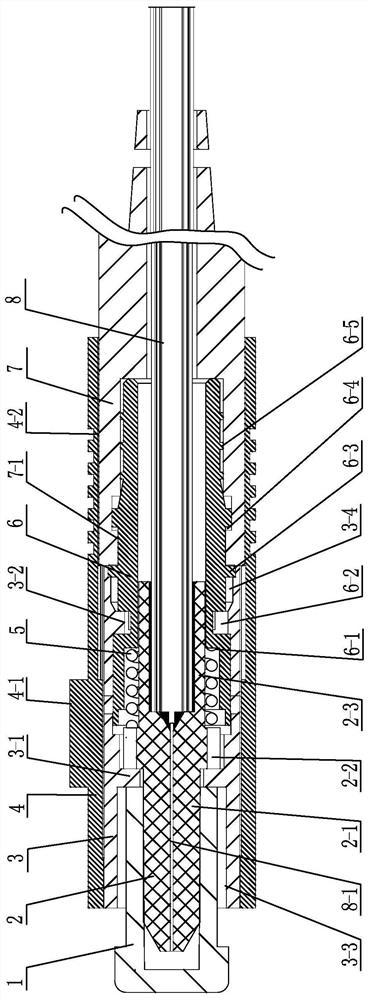

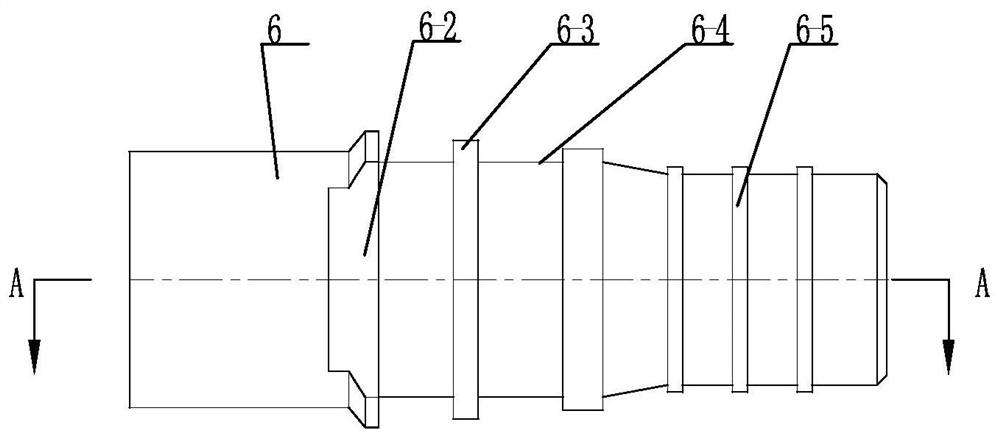

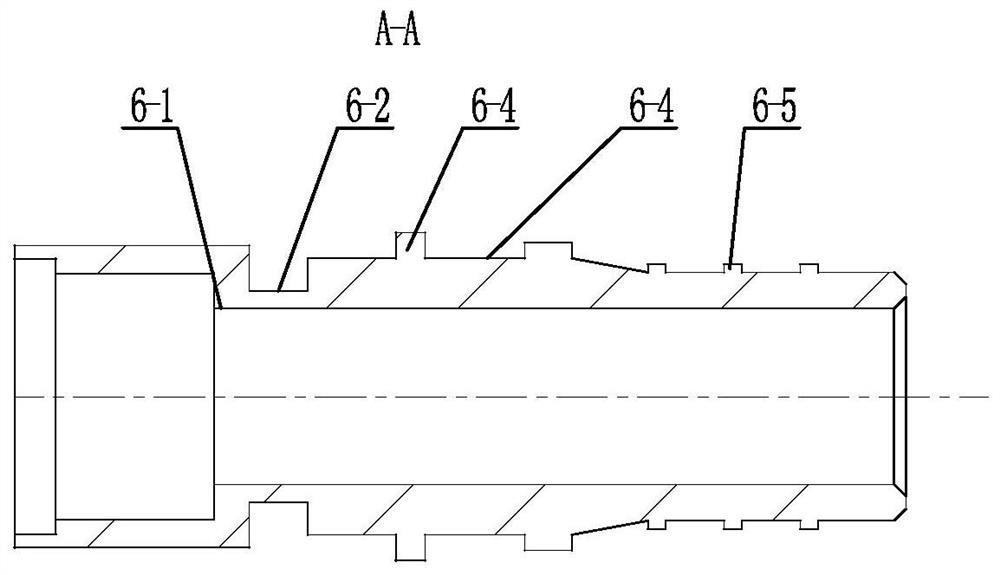

[0019] See figure 1 As shown, the optical fiber active connector of the crimp-free structure of the present invention includes an inner sleeve 3 , a connecting sleeve 6 , an outer sleeve 4 , a ceramic ferrule 2 and a sheath tube 7 .

[0020] See figure 1 As shown, the inner sleeve 3 of the present invention includes a front limiting hole 3-3 for matching with the adapter when docking, a shoulder 3-1 for limiting the position of the tailstock with groove 2-2 and a shoulder for connecting with the connecting sleeve. 6. The rear mounting hole 3-4 of the connection is fixed by the inner sleeve 3 and the adapter during docking, and the outer protrusion 4-1 on the outer sleeve 4 is clamped and fixed to prevent the connector from being displaced and affecting the docking performance. See figure 1 As shown, the dustproof cap 1 of the present invention is tightly sleeved on the ceramic pin 2 and extends into the inner sleeve 3, and is limited by the shoulder 3-1. The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com