Method for testing optical image stabilization performance of camera driving motor

A technology for driving motors and testing methods, which is applied in optical instrument testing, vibration testing, machine/structural component testing, etc. It can solve the problems of camera module sample scrapping, production cost increase, OIS performance evaluation, etc. The effect of reaching the standard, increasing production efficiency, and avoiding rework and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

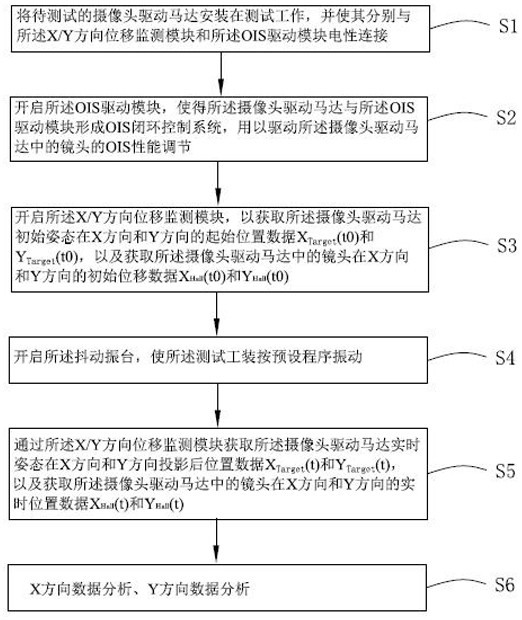

[0032] Please also see Figure 1-2 , the present invention provides a method for testing optical image stabilization performance of a camera drive motor, providing:

[0033] Shaking vibration table 1 is used to simulate the shaking process of actual hand-held shooting by people.

[0034] The test fixture 2 is used to mount the camera drive motor 10 carrying the lens 101 , which includes an X / Y direction displacement monitoring module 21 and an OIS drive module 22 .

[0035] In this embodiment, the camera drive motor 10 is built-in to detect the X-direction and Y-direction displacement of the internal lens 101 and generate the Hall signal X respectively. Hall There are at least two groups of Hall sensors, that is, a group of X-direction Hall sensors 102a for detecting the displacement of the lens 101 in the X direction and a group of Y-direction Hall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com