Variable compression ratio engine

A technology of engine and compression ratio, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., and can solve the problem of slow adjustment of compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The embodiment of the present invention provides a variable compression ratio engine, which can solve the technical problem of slow adjustment speed of the existing engine compression ratio.

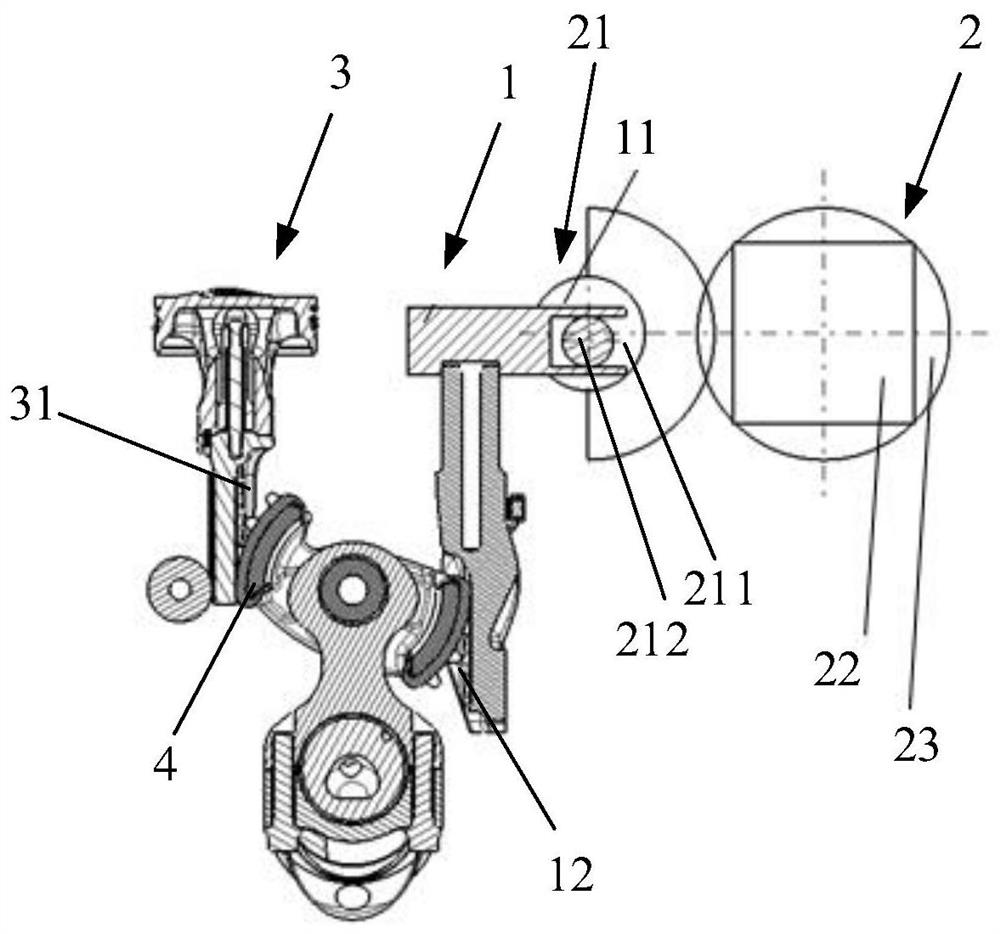

[0031] See figure 2 As shown, a variable compression ratio engine includes: a control piston 1 and a driving and locking mechanism 2.

[0032] The control piston 1 and the cylinder piston 3 of the engine are arranged side by side. The control piston 1 is configured to drive the cylinder piston 3 to move downward or upward when the control piston 1 moves up or down to adjust the top dead center position of the cylinder piston 3 , And the control piston 1 is provided with a clamping portion 11.

[0033] The driving and locking mechanism 2 is provided on the side of the control piston 1, and the driving and locking mechanism 2 is provided with a movable part 21 movably connected with the clamping part 11, and the movable part 21 is used to drive the control piston 1 to move up or down, or ...

Embodiment 2

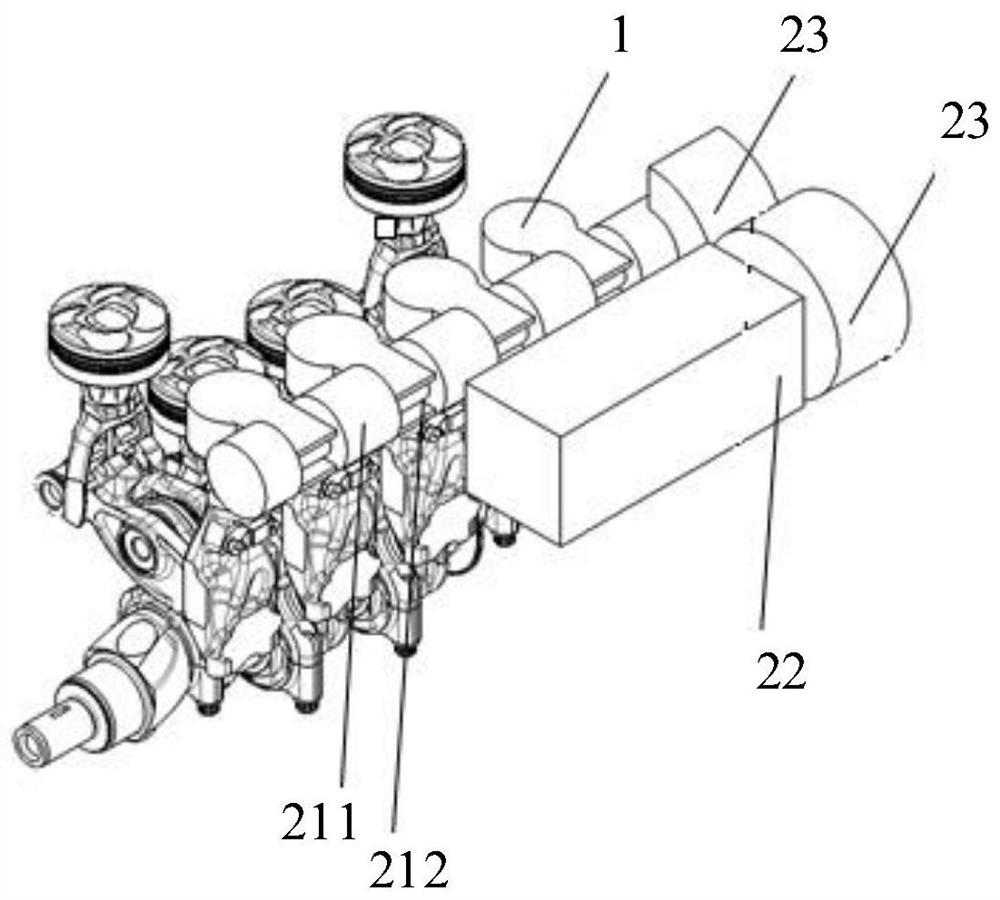

[0036] On the basis of Example 1, see figure 2 As shown, as an optional embodiment: the clamping portion 11 is a rectangular opening groove opened at the upper end of the control piston 1. The movable part 21 includes a rotating shaft 211 and an eccentric shaft 212 provided on the rotating shaft 211. The eccentric shaft 212 is inserted into the rectangular opening slot, and the rotating shaft 211 rotates so that the eccentric shaft 212 drives the control piston 1 to move upward or downward.

[0037] Specifically, the driving and locking mechanism 2 is further provided with a driving part 22, which drives the rotating shaft 211 to rotate. The rotating shaft 211 rotates to make the eccentric shaft 212 move up and down in the vertical direction. Since the eccentric shaft 212 is inserted into the rectangular opening groove, the control piston 1 also moves up and down.

[0038] It should be noted that the embodiment of the present invention uses a control piston 1 and a cylinder piston...

Embodiment 3

[0041] On the basis of Example 2, see figure 2 As shown, as an optional implementation manner: a reducer 23 is also provided between the output shaft of the control motor and the rotating shaft 211, which facilitates the control of the motor to be arranged on the side of the engine and makes the structure more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com