Advanced grouting construction method for underground excavated tunnel

A technology of advanced grouting and construction methods, which is applied in the direction of tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems that the grouting effect cannot be guaranteed, affects the construction progress, and the grouting time is long, etc., and achieves shortening of the advance grouting distance, Speed up the construction progress and improve the quality of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] An advanced grouting construction method for an underground excavation tunnel according to an embodiment of the present invention, the construction method includes the following steps:

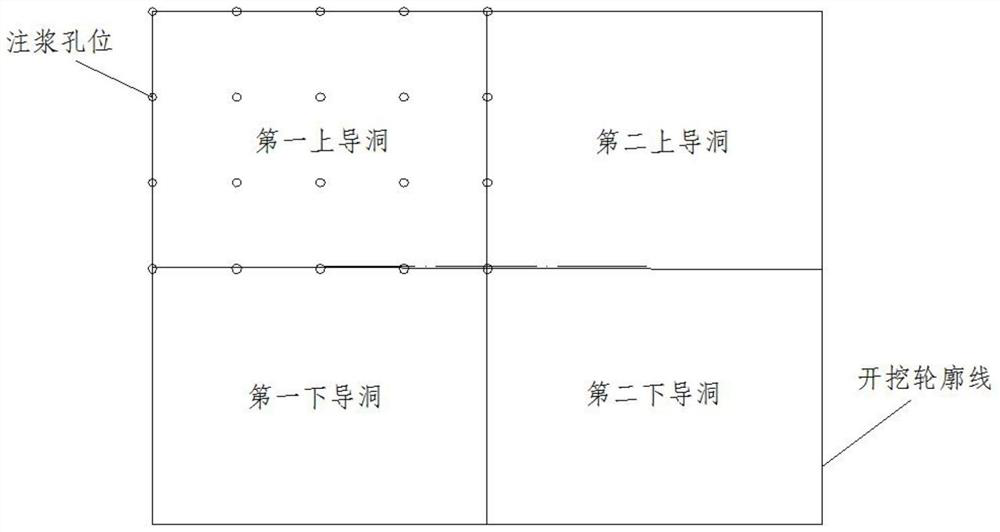

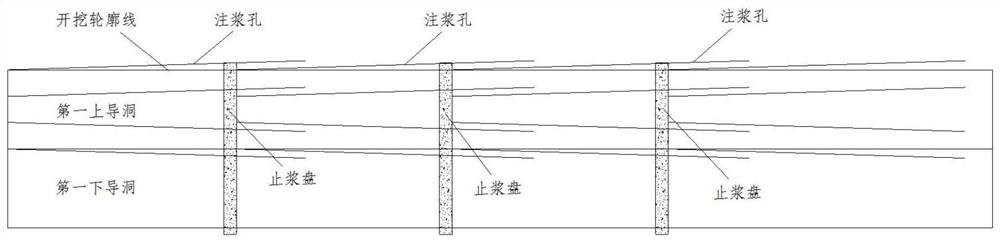

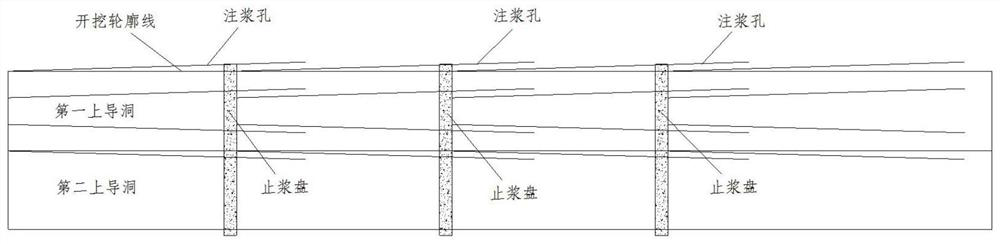

[0028] Step 1: Divide the full-section curtain grouting reinforcement area of the underground excavation tunnel into the first upper pilot tunnel, the second upper pilot tunnel, the first lower pilot tunnel and the second lower pilot tunnel; among them, the first upper pilot tunnel and the second The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com