Automatic turn-over device for long-roll sock legs and control method

An automatic and sock tube technology, which is applied in the field of textile machinery, can solve problems such as unsatisfactory effects, achieve the effects of reducing labor intensity and labor costs, ensuring product quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

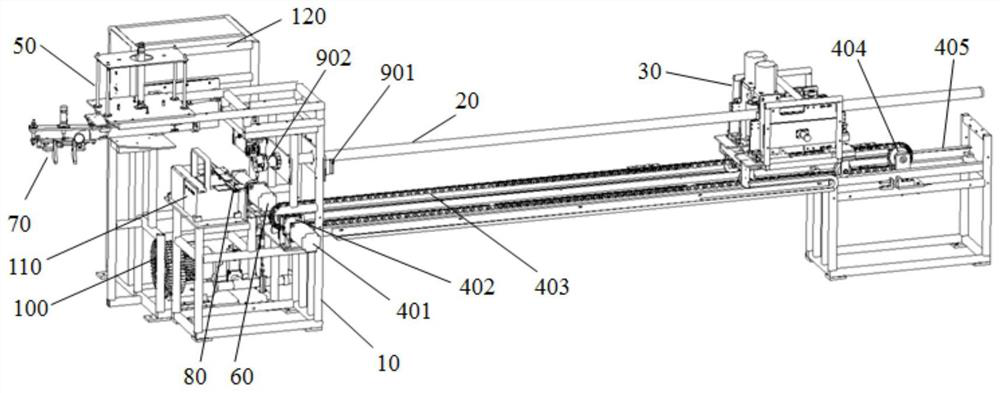

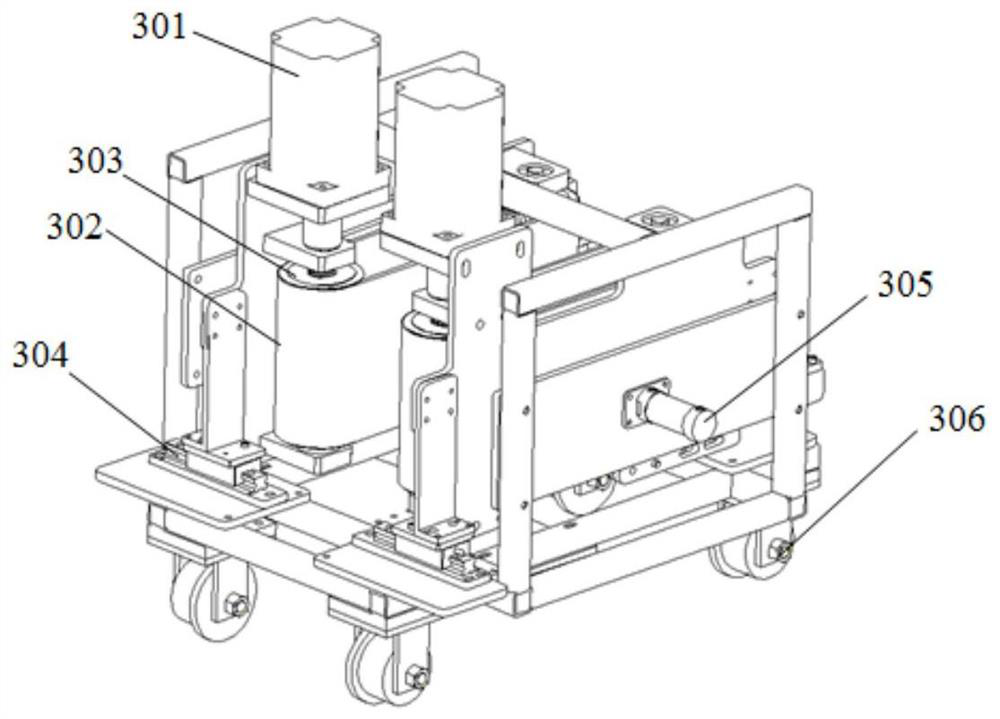

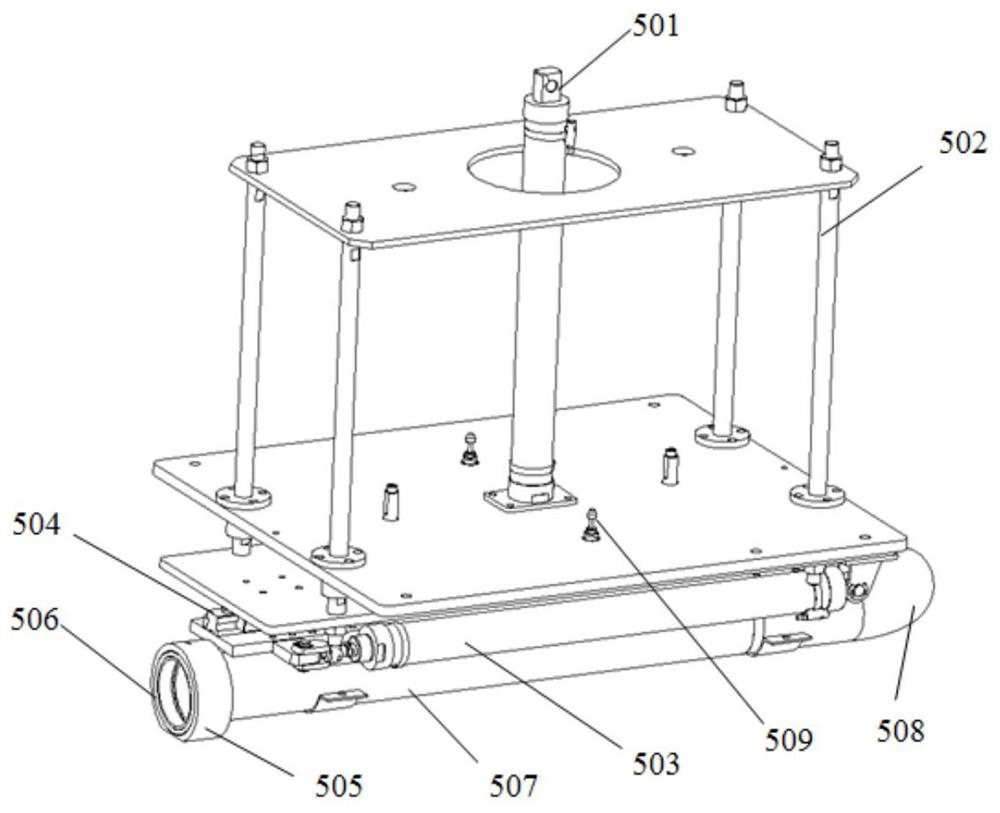

[0069] Such as Figure 1 to Figure 5 As shown, a long-rolled sock tube automatic turning device according to the embodiment of the present invention includes a frame 10, a sock tube 20, a feeding compression mechanism 30, a chain drive mechanism 40, a lifting suction mechanism 50, and a winding roller mechanism 60 , manipulator mechanism 70, toe clamping mechanism 80, detection sensor group 90, high pressure fan 100, automatic strapping machine 110 and control cabinet 120.

[0070] The specific instructions are as follows:

[0071] It includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com