A kind of nano antibacterial and antifouling table and chair plastic particles and preparation method

A plastic particle and anti-fouling technology, applied in the field of functional plastics, can solve the problems of difficult to disinfect bacteria, easy leakage of inorganic antibacterial agents, and affect the durability of antibacterial, so as to improve the antibacterial effect, easy and quick start-up, and improve antibacterial performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

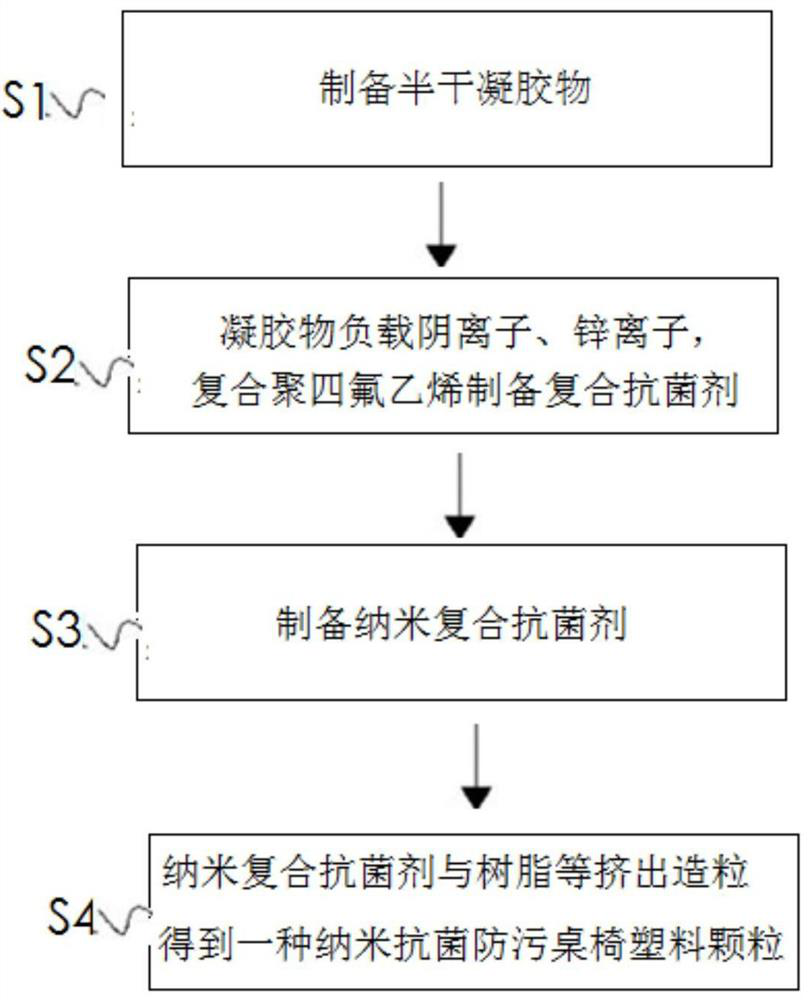

Method used

Image

Examples

Embodiment 1

[0036] S1. Add sodium methyl silicate to water and disperse sodium methyl silicate in water through high-speed dispersion at 800rpm. While dispersing at high speed, gradually add citric acid, and continue to use test paper to test until the pH is 4, and continue to stir for 15 minutes. , to form a gel solution; the gel solution was left to stand for 2 hours to obtain a gel, then washed with deionized water and vacuum filtered to remove most of the water absorbed by the gel to obtain a semi-dry gel;

[0037] S2, 10kg of the semi-dried gel obtained in step S1, 3kg of zinc nitrate hexahydrate, 1kg of silver nitrate, and 30kg of deionized water are mixed and stirred evenly, and then 3kg of polytetrafluoroethylene emulsion with a solid content of 40% (wt) is added, After the dispersion is uniform, it is sent to the centrifugal spray dryer, and the dispersion liquid is dispersed and sprayed in the form of mist under the action of centrifugal force through the high-speed rotation of 2...

Embodiment 2

[0041] S1. Add sodium methyl silicate to water and disperse at a high speed of 1200rpm to make it difficult to disperse sodium methyl silicate in water. While dispersing at high speed, gradually add citric acid, and continue to use test paper to test until the pH is 5, and continue to stir After 15 minutes, a gel solution was formed; the gel solution was left to stand for 2 hours to obtain a gel product, and then washed with deionized water and vacuum filtered to remove most of the water absorbed by the gel to obtain a semi-dry gel product;

[0042] S2, 15kg of the semi-dry gel thing obtained in step S1, 5kg of zinc nitrate hexahydrate, 2kg of silver nitrate, and 50kg of deionized water are mixed and stirred evenly, and then 3kg of polytetrafluoroethylene emulsion with a solid content of 40% (wt) is added, After the dispersion is uniform, it is sent to the centrifugal spray dryer, and the dispersion liquid is dispersed and sprayed in the form of mist under the action of centrif...

Embodiment 3

[0046] S1. Add sodium methyl silicate to water and disperse at a high speed of 800rpm to make it difficult to disperse sodium methyl silicate in water. While dispersing at high speed, gradually add citric acid, and continue to use test paper to test until the pH is at 5, and continue to stir 10min to form a gel solution; let the gel solution stand for 1-2 hours to obtain a gel, then wash with deionized water and vacuum filter to remove most of the water absorbed by the gel to obtain a semi-dry gel;

[0047] S2, 12kg of the semi-dried gel obtained in step S1, 3kg of zinc nitrate hexahydrate, 3kg of silver nitrate, and 50kg of deionized water are mixed and stirred evenly, and then 3kg of polytetrafluoroethylene emulsion with a solid content of 40% (wt) is added, After the dispersion is uniform, it is sent to the centrifugal spray dryer, and the dispersion liquid is dispersed and sprayed in the form of mist under the action of centrifugal force through the high-speed rotation of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com