Preparation method of biapenem bulk drug

A technology for biapenem and raw materials, applied in the field of preparation of biapenem raw materials, which can solve the problems of difficult control of product particle size, increased production costs, uneven particle size distribution, etc., to facilitate industrial packaging and storage , easy to control, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 Preparation of Crude Biapenem

[0086]

[0087] Add 10kg of biapenem intermediate (II), 89kg of tetrahydrofuran, and 200kg of purified water into the hydrogenation kettle, stir and dissolve, add 60kg of ethyl acetate, 4kg of 2,6-lutidine, and 3kg of 7.5% Pd / C. 1.0~1.2MPa, hydrogenation reaction at 30~35°C for 2 hours, stop the reaction, filter, wash the filter cake with 20kg purified water, separate the phases, transfer the water phase to the crystallization kettle, cool down to 2~7°C, add 356kg tetrahydrofuran, control Adding speed, the dropwise addition is completed in 1 hour, keep warm at 2-7°C, grow crystals for 2 hours, filter, wash the filter cake with 10kg of tetrahydrofuran, and dry in vacuum to obtain 5.02kg of crude biapenem, with a yield of 75%, by HPLC normalization method The detection purity is: 96.3%, the impurity A is 0.59%, and the impurity B is 0.27%.

Embodiment 2

[0089] Add 450 g of purified water to the reaction flask, control the temperature to 20°C, and add 10 g of the crude biapenem obtained in Example 1 under stirring, stir to dissolve, control the temperature to 20°C, add 1 g of activated carbon, stir for 10 minutes, and filter out activated carbon, the filtrate was cooled to 5°C, and set aside;

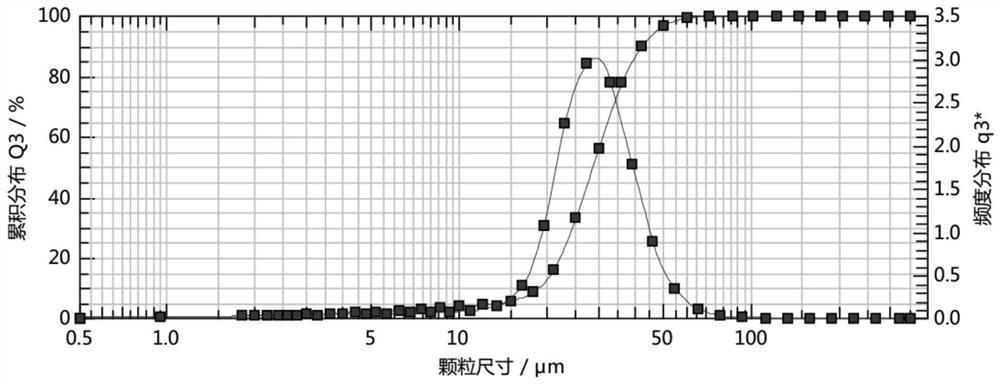

[0090] Add 382.5ml of acetone and 67.5ml of ethanol to the reaction flask, cool down to 10°C, add dropwise 18ml of the above-mentioned filtrate under stirring, stir for 60 minutes, add the rest of the above-mentioned filtrate dropwise, control the rate of addition, and complete the dropwise addition in 1 hour. Stir at 15°C for 30 minutes, cool down to 7°C, continue to stir for 1.5 hours, filter, wash the filter cake with 20g of acetone, and dry it under vacuum at 40-50°C to obtain 9.48g of biapenem raw material, with a yield of 94.8%, HPLC The purity is 99.77%, the impurity A is 0.1%, the impurity B is 0.01%, and the particle size distr...

Embodiment 3

[0095] Add 450 g of purified water to the reaction flask, control the temperature to 30°C, and add 10 g of the crude biapenem obtained in Example 1 under stirring, stir to dissolve, control the temperature to 30°C, add 1 g of activated carbon, stir for 10 minutes, and filter out activated carbon, the filtrate was cooled to 10°C, and set aside;

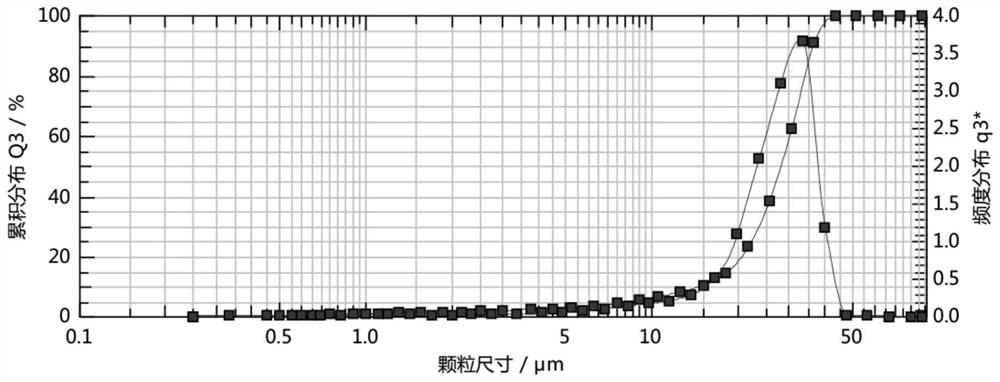

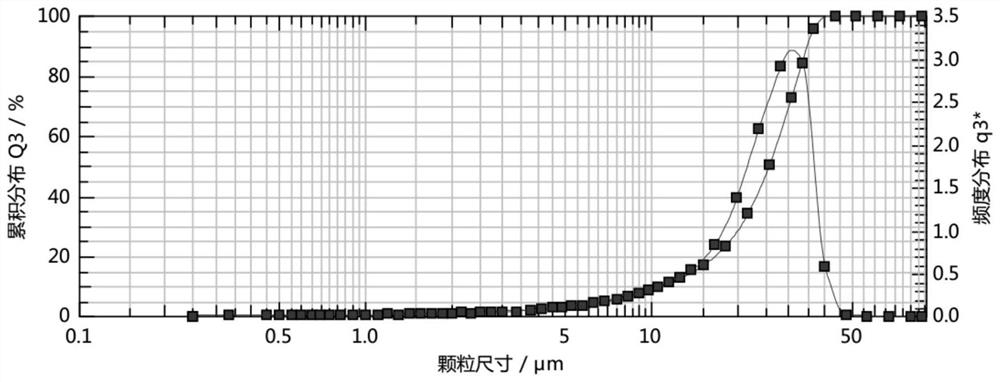

[0096] Add 382.5ml of acetone and 67.5ml of ethanol to the reaction flask, cool down to 15°C, add dropwise 18ml of the above-mentioned filtrate under stirring, stir for 60 minutes, add the rest of the above-mentioned filtrate dropwise, control the rate of addition, and complete the dropwise addition in 1.5 hours. Stir at 20°C for 30 minutes, cool down to 12°C, continue to stir for 1.5 hours, filter, wash the filter cake with 20g of ethanol, and dry it under vacuum at 40-50°C to obtain 9.45g of biapenem raw material with a yield of 94.5%, HPLC The purity is 99.73%, the impurity A is 0.11%, the impurity B is 0.01%, and the particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com