Filtering, extruding and cutting-off system for mixed compounds

A technology of mixing rubber, extruding and conveying, which is applied in recycling technology, metal processing, plastic recycling, etc., and can solve the problems of large volume, large output, and small output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

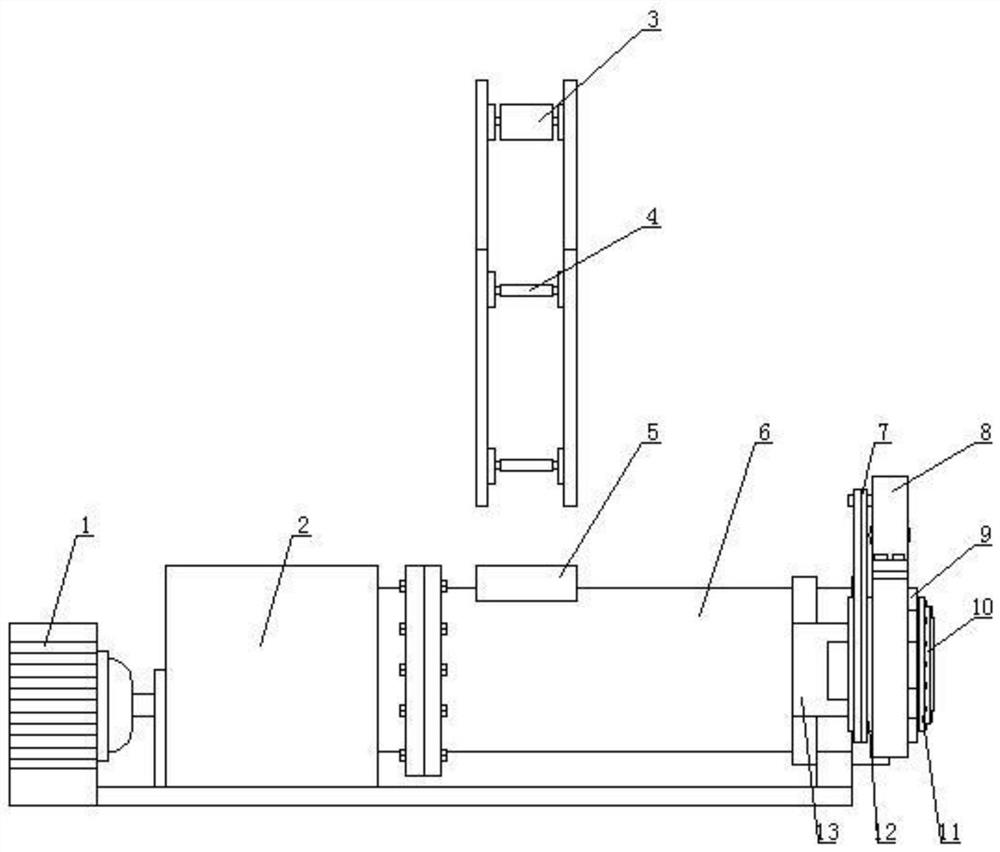

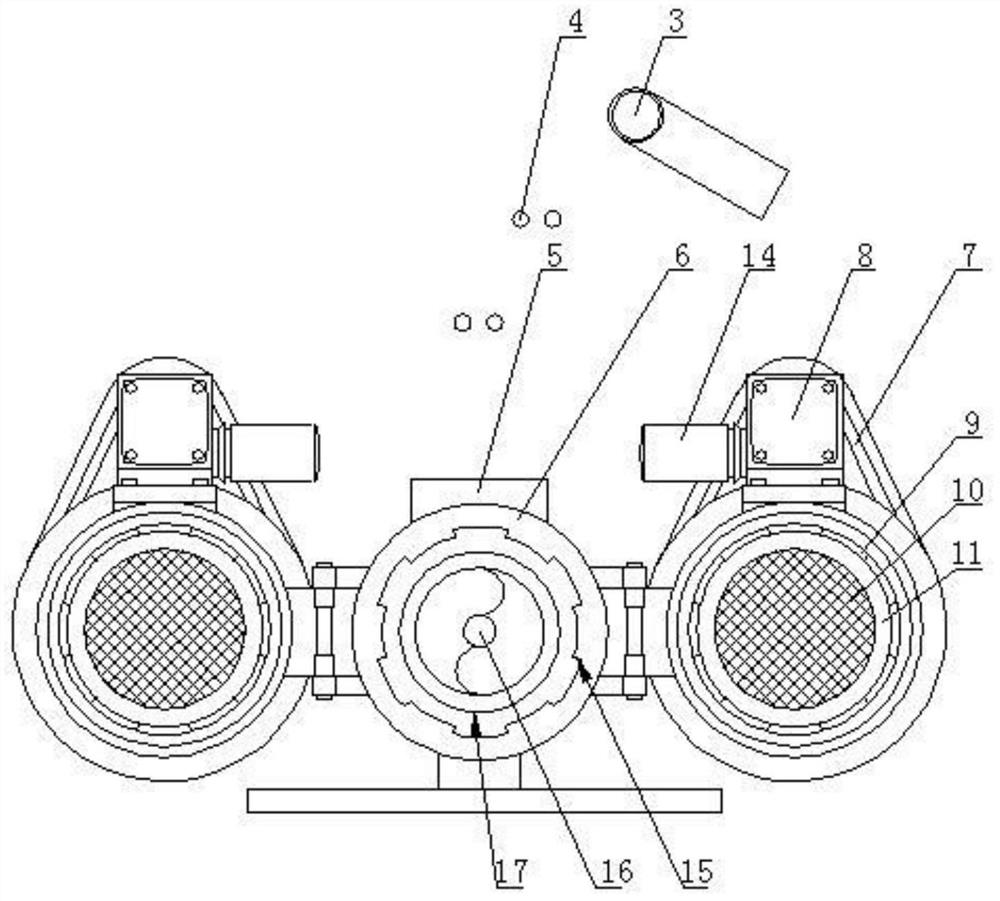

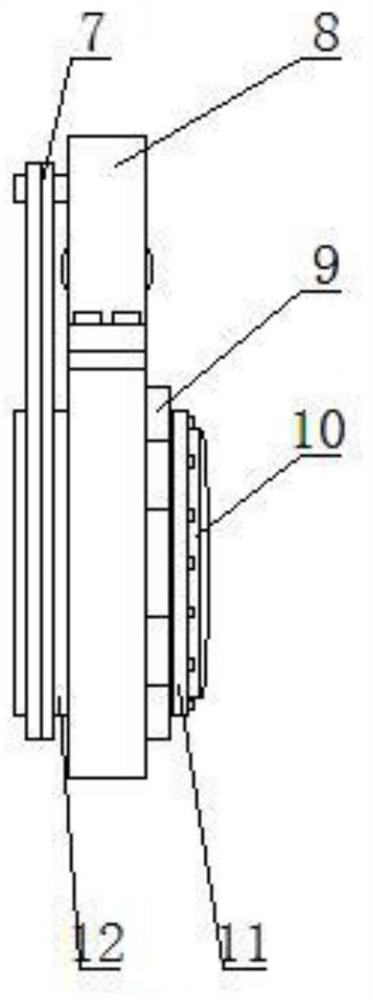

[0024] A filtering, extrusion, and cutting system for compounded rubber. The innovation of the present invention is that it includes a lifting device, a tablet pressing device, an extrusion conveying device, and a filtering and cutting device. The lifting device includes a lifting roller 3, and the output of the lifting roller is The side is located above the filtering device, and the tablet pressing device is installed between the lifting roller and the feeding port 5 of the extrusion conveying device, and the filtering and cutting device is installed at the discharge port position of the extruding conveying device, and the lifting roller It is used to lift the strip-shaped rubber compound to be filtered to the top of the extrusion convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com