Automatic bamboo slicing machine

An automatic, fragmented technology, applied in mechanical equipment, multi-purpose machinery, sugarcane machinery processing, etc., can solve the problems of single size and different sizes of bamboo pieces, and achieve the effects of reducing processing, improving production efficiency, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

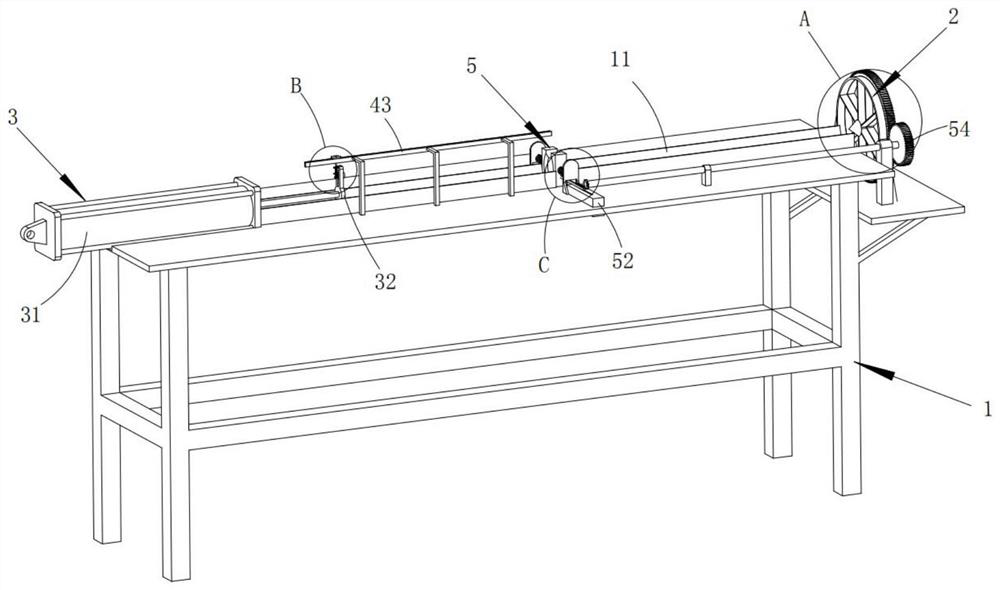

[0040] Such as Figure 1 to Figure 5 As shown, the invention provides a kind of automatic bamboo fragmentation machine, comprising:

[0041] Workbench 1, which is provided with a feeding trough 11 arranged along its length direction;

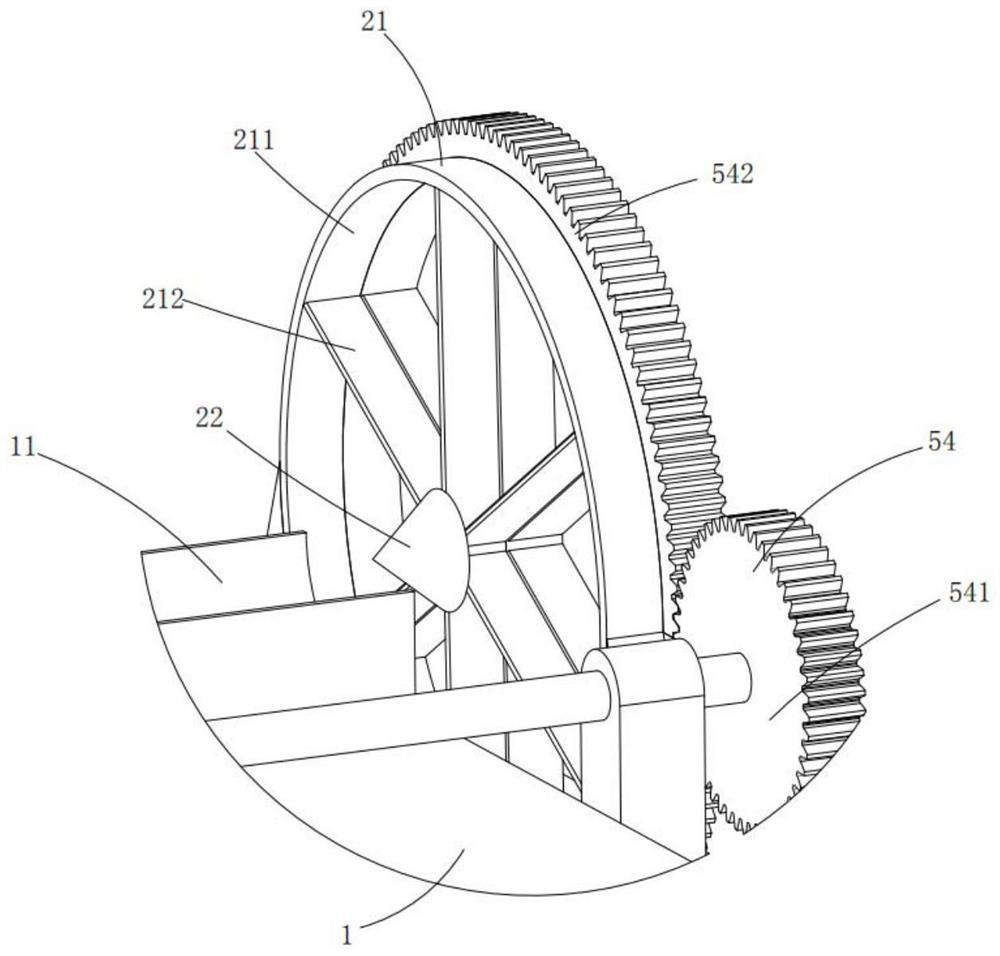

[0042] Cutting device 2, said cutting device 2 comprises two groups of cutter assemblies 21 arranged at one end of said feeding trough 11 and coaxially arranged, and the two groups of cutter assemblies 21 are rotatably connected;

[0043] The power device 3, the power device 3 includes a drive assembly 31 arranged at the other end of the feed chute 11 relative to the cutter assembly 21 and is power-connected with the drive assembly 31 and slidably arranged on the feed chute 11 Inside the push assembly 32, the bottom of the push assembly 32 is fixedly provided with a guide assembly 324;

[0044] The pressing device 4, the pressing device 4 includes a pressing assembly 41 sliding up and down on the top of the pushing assembly 32 and a control as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com