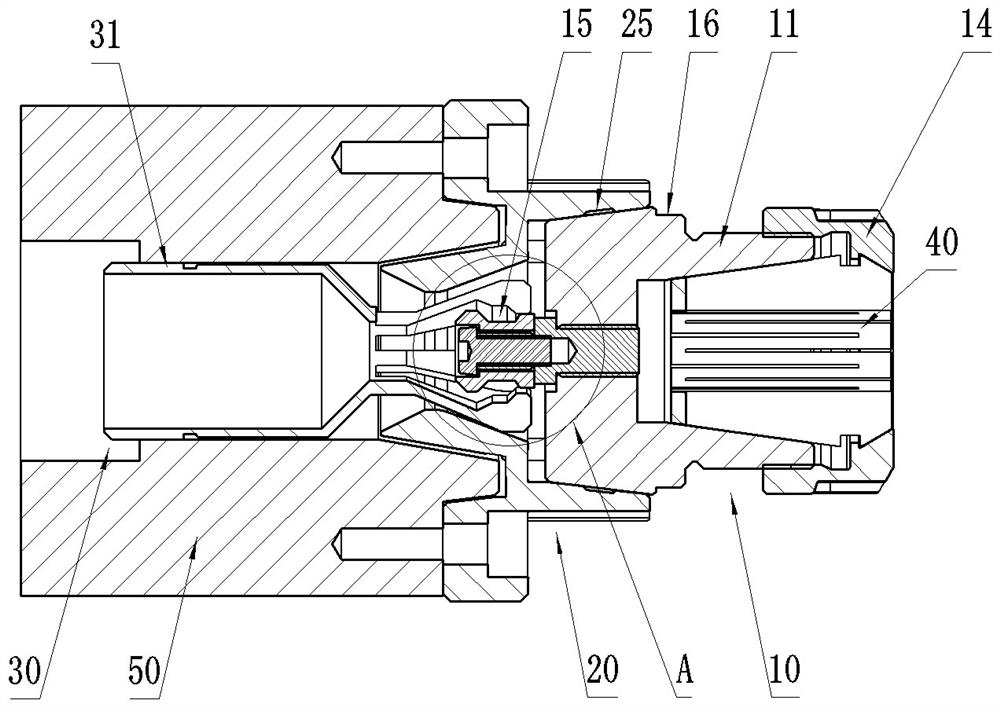

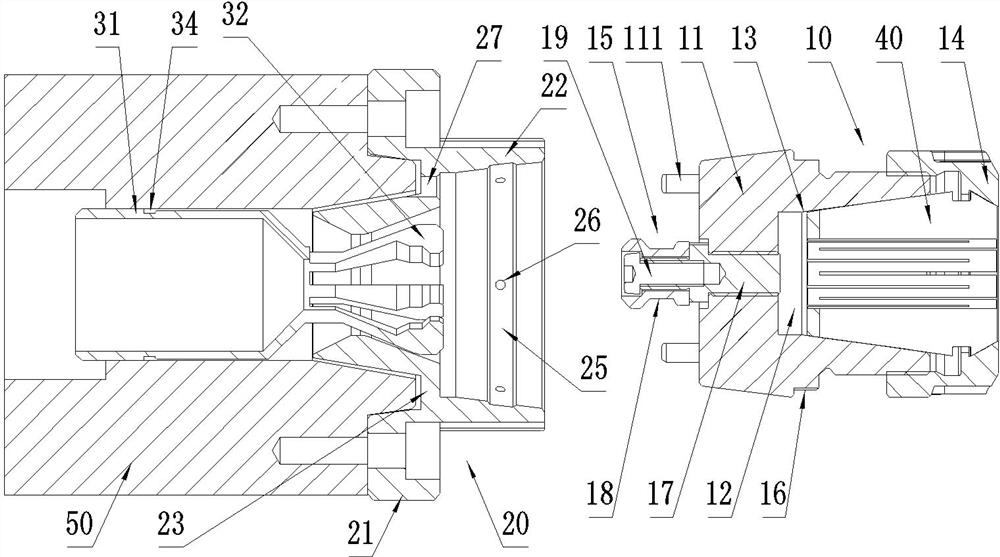

Workpiece quick-change tool for lathe

A technology for lathes and workpieces is applied in the field of quick-change tooling for workpieces for lathes, which can solve problems such as affecting production efficiency and taking a long time to load and unload workpieces, and achieve the effects of improving positioning accuracy, meeting the needs of rotating processing, and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

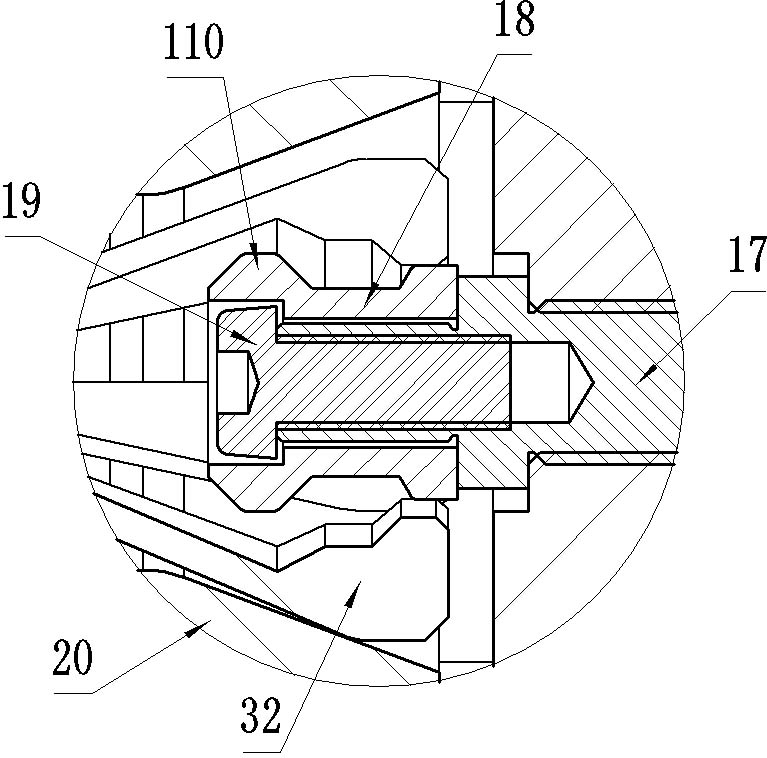

[0072] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the slider 15 includes a connecting column 17 and a sleeve-shaped main body 18, and the connecting column 17 and the collet chuck 11 are arranged separately, while in this embodiment, The connecting column 17 is integrally arranged on the collet chuck 11 .

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the sleeve-shaped main body 18 of the slider 15 is sheathed on the connecting column 17 in a radially floating manner, while in this embodiment, the sleeve-shaped main body 18 and The connecting column 17 is positioned and matched in the radial direction, relying on the slight deformation of the petal-shaped claw body 32 to avoid the problem of over-positioning. Of course, in other implementations, the slider 15 can also be a single part.

Embodiment 4

[0076] The difference between this embodiment and Embodiment 1 is that both sides of the large-diameter part of the slider 15 in Embodiment 1 are cylindrical surfaces, while in this embodiment, the large-diameter part of the slider 15 is formed by a sleeve-shaped main body 18 The outer flange of the outer flange is formed, and the front end surface of the outer flange is used to axially stop and cooperate with the petal-shaped main body on the collet pulling claw 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com