Small bamboo shoot peeling machine for food processing

A food processing and peeling machine technology, applied in the field of peeling machines, can solve the problems of human hands being cut by bamboo shoots, reducing work efficiency, easy to produce fatigue, etc., and achieving the effect of reducing work difficulty, improving efficiency, and good collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

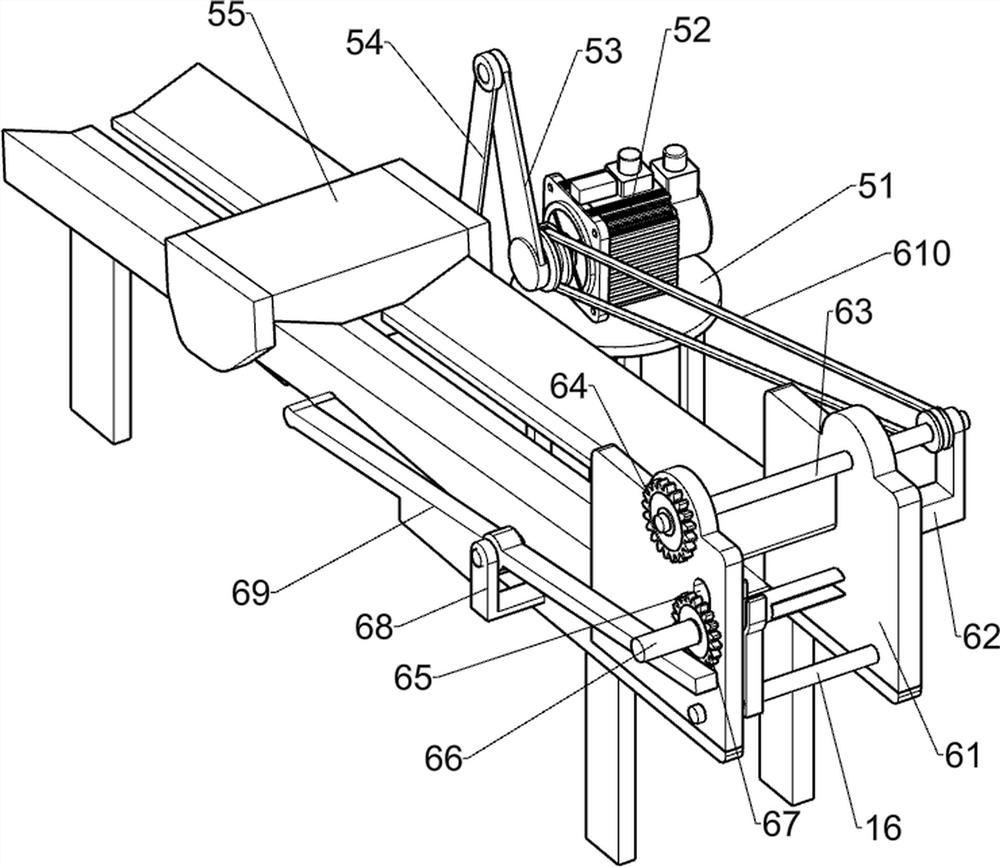

[0022] A kind of small bamboo shoot peeling machine for food processing, such as Figure 1-2 As shown, it includes a base 1, a support column 2, an inclined plate 3, a cutter 4, a pushing mechanism 5, a peeling mechanism 6 and a collection box 7. Two sets of support columns 2 are arranged on the front side of the top of the base 1, and two sets of support columns 2 are provided. Each is a group, and a swash plate 3 is fixedly connected between the tops of the support columns 2, a cutter 4 is provided in the middle of the left end of the swash plate 3, a pushing mechanism 5 is provided on the right front side of the top of the base 1, and a peeling mechanism is provided on the left side of the swash plate 3. 6. A collection box 7 is provided on the top left side of the base 1 .

[0023] When people need to use this device, first people put the small bamboo shoots in the middle of the inclined plate 3, and then people can start the pushing mechanism 5, so that the pushing mechan...

Embodiment 2

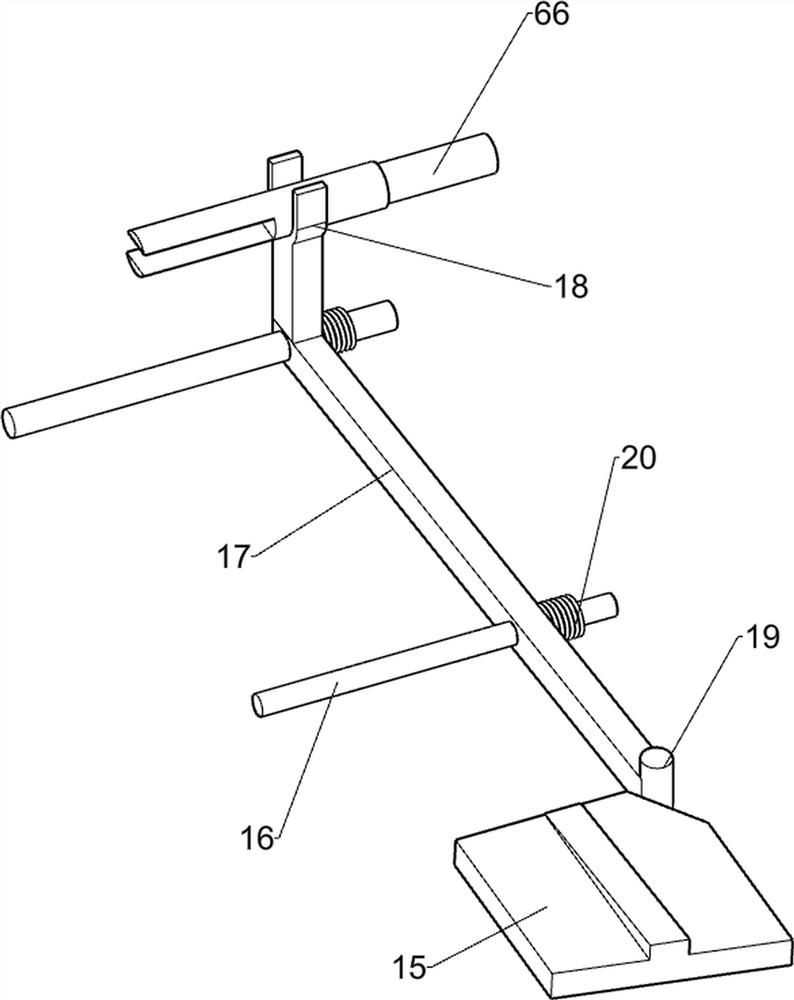

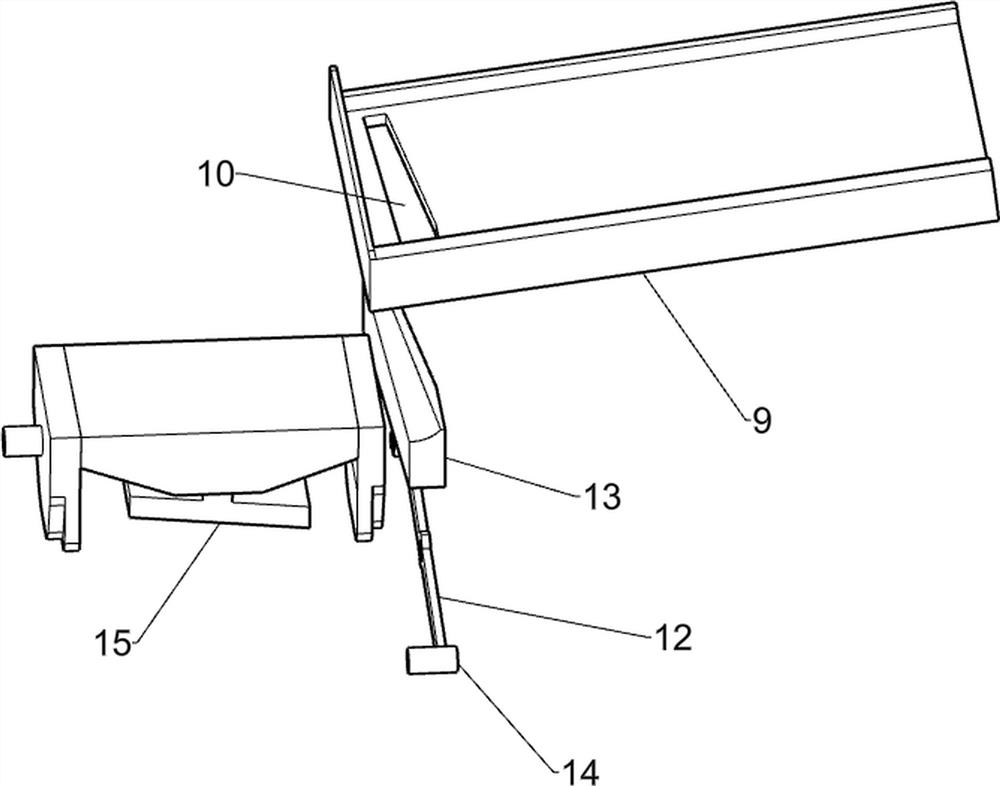

[0029] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 and Figure 5 As shown, it also includes a support frame 8, a blanking plate 9, a second rotating shaft 11, a third rotating rod 12, an extrusion block 13 and a driving rod 14, and the right rear side of the top of the base 1 is fixedly connected with a support frame 8, and the support frame 8 is provided with a blanking plate 9, the front portion of the blanking plate 9 has a chute 10, the right front side of the support frame 8 is provided with a second rotating shaft 11, and the second rotating shaft 11 is provided with a third rotating rod 12 in a rotating manner. The 3rd rotating rod 12 left-hand rotations are provided with extruding block 13, and extruding block 13 slides in chute 10, and the 3rd rotating rod 12 right-hand ends are provided with driving rod 14, and driving rod 14 cooperates with slide block 55.

[0030]First, people place the small bamboo shoots on the blanking plate 9, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com