Welding method and device for flexible circuit board and printed circuit board

A flexible circuit board and printed circuit board technology, which is applied in the structural connection of printed circuits, printed circuit components, printed circuits, etc., can solve the problems of not being able to arrange devices, increase the layout space of PCB and FPC, and reduce bonding Reinforcing plate steps, reducing the steps of peeling the reinforcing plate, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present application are described below with reference to the drawings in the embodiments of the present application. The terms used in the implementation of the embodiments of the present application are only used to explain the specific embodiments of the present application, and are not intended to limit the present application.

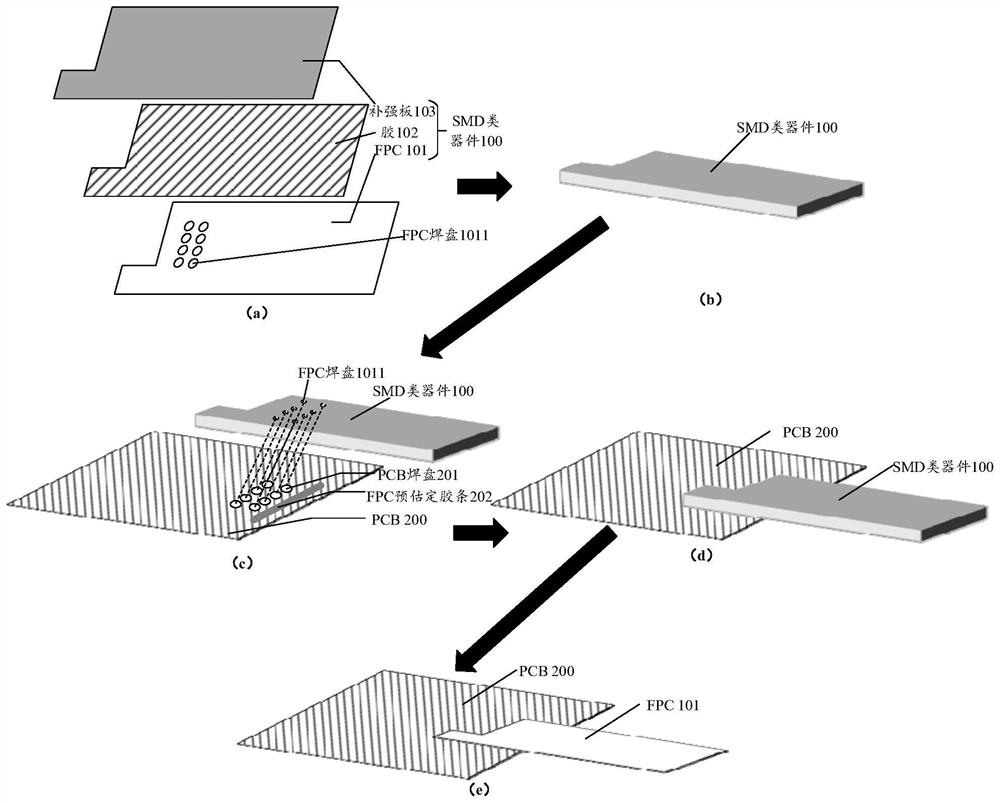

[0055] In order to reduce the layout space occupied by interconnection products between flexible and rigid boards, embodiments of the present application provide a welding method and device for a flexible circuit board and a printed circuit board.

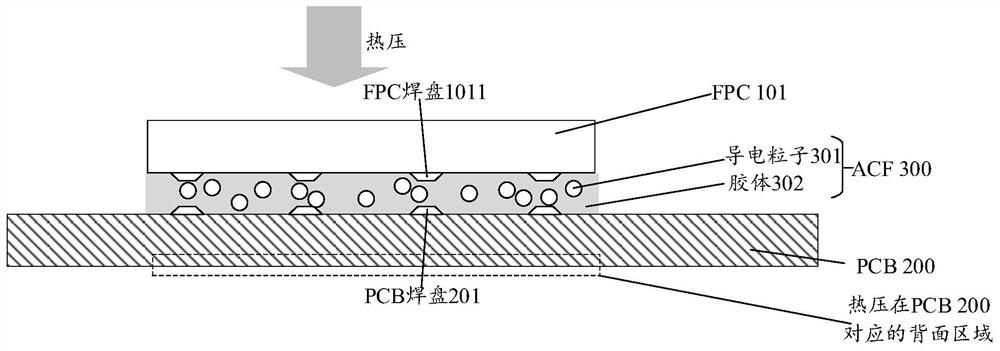

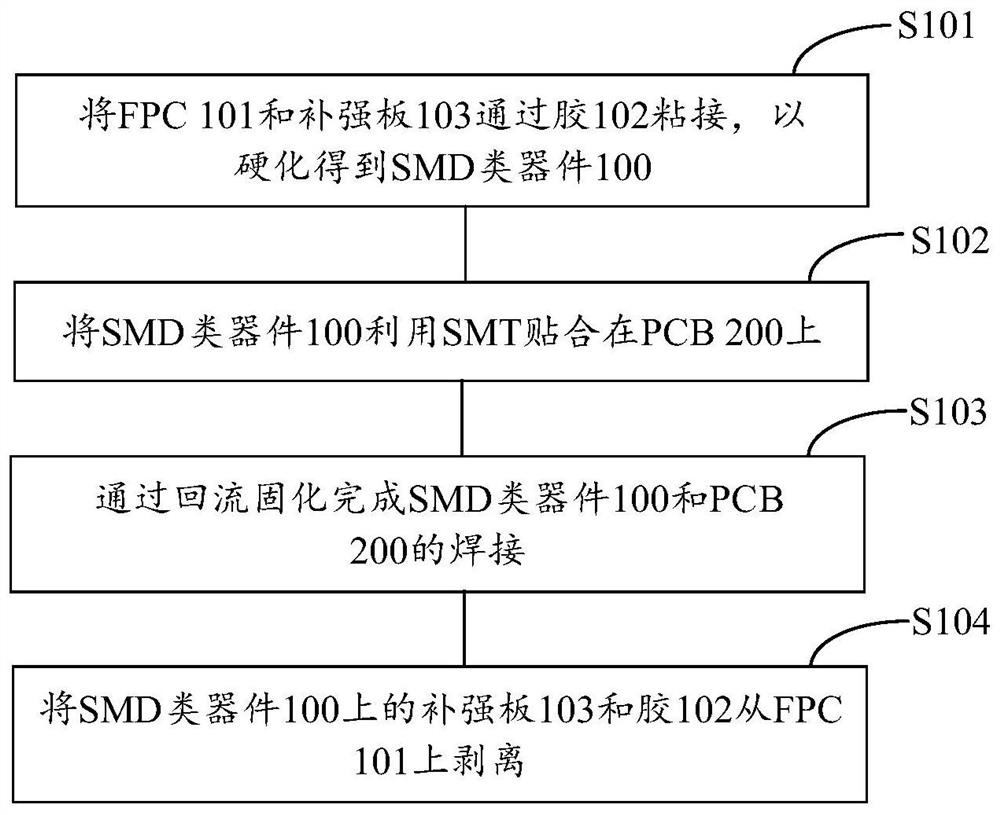

[0056] In this welding method, first, the FPC is hardened, for example, a hard reinforcing plate is glued on the FPC. Then, use surface mount technology (surface mount technology, SMT) to attach the hardened FPC to the PCB similar to surface mount devices (surface mounted devices, SMD). Soldering is then completed by reflow curing. Finally, the reinforcement board is peeled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com