Power cable protection tube

A power cable and cable protection technology, which is applied in the field of power cables, can solve the problems of reducing the use effect of the protective tube, failure of the protective effect of the protective tube, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

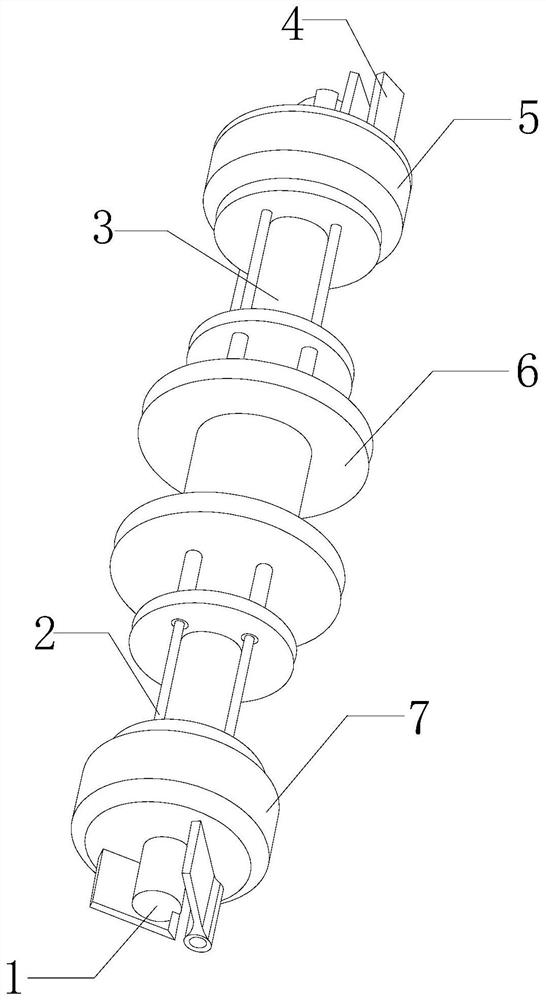

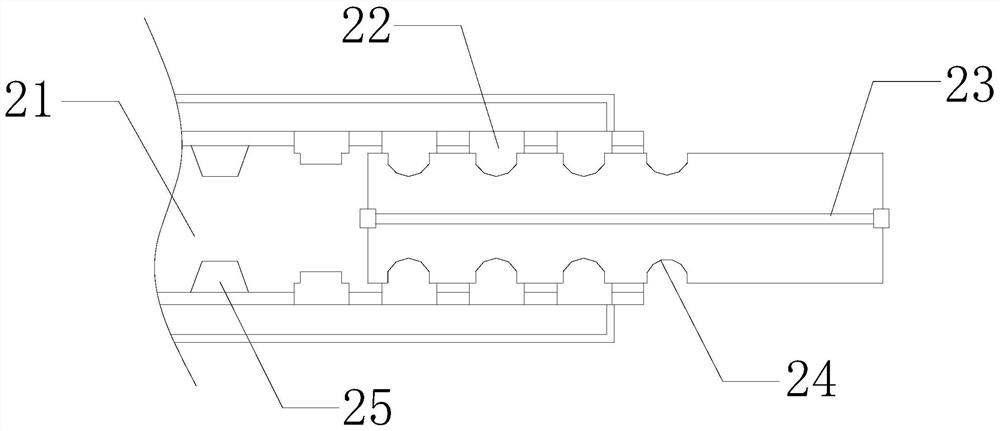

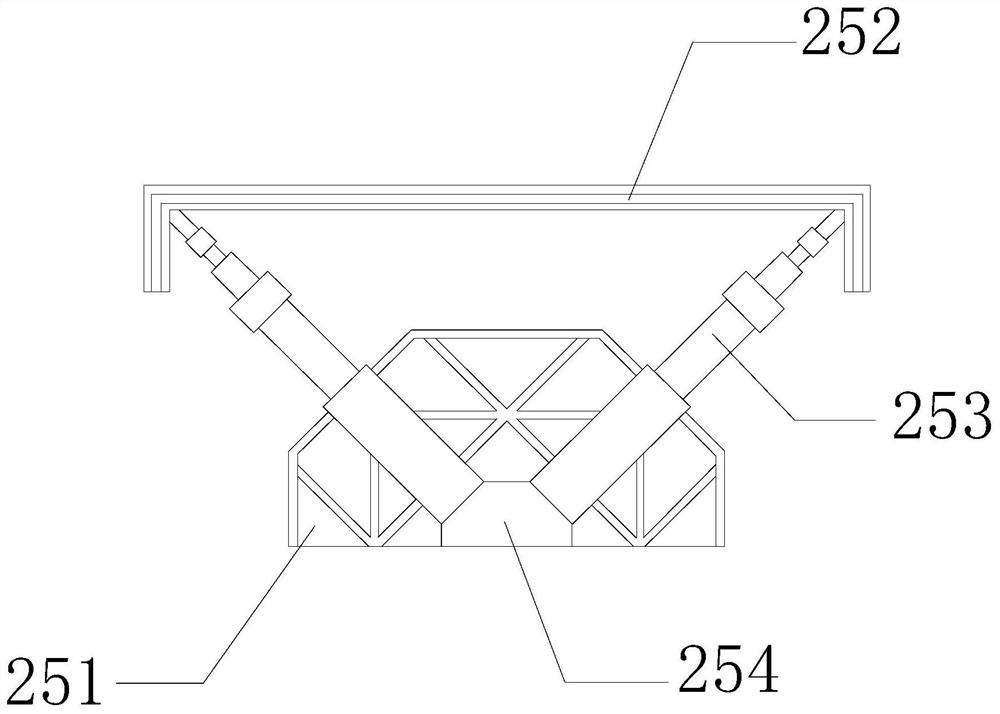

[0032] see figure 1 , the present invention provides a technical solution: a power cable protection tube, the structure of which includes a connection port 1, a telescopic device 2, a sleeve 3, a sealing device 4, a cable protection shell 5, a chuck 6, and a terminal 7. The connection port 1 is fixedly connected with the terminal 7, the terminal 7 is fixedly installed on the front end of the sleeve 3, the sleeve 3 is provided with a telescopic device 2, and the inner wall of the telescopic device 2 is closely attached to the outer wall of the sleeve 3 The sleeve 3 is set inside the cable protection shell 5, the front end of the cable protection shell 5 is provided with a terminal 7, and the inside of the cable protection shell 5 is provided with a sealing device 4, and the sealing device 4 is closely attached to the On the inner wall of the cable protection case 5, a chuck 6 is provided in the middle of the cable protection case 5, the chuck 6 is inlaid with the cable protect...

Embodiment 2

[0042] see figure 1 , the present invention provides a technical solution: a power cable protection tube, the structure of which includes a connection port 1, a telescopic device 2, a sleeve 3, a sealing device 4, a cable protection shell 5, a chuck 6, and a terminal 7. The connection port 1 is fixedly connected with the terminal 7, the terminal 7 is fixedly installed on the front end of the sleeve 3, the sleeve 3 is provided with a telescopic device 2, and the inner wall of the telescopic device 2 is closely attached to the outer wall of the sleeve 3 The sleeve 3 is set inside the cable protection shell 5, the front end of the cable protection shell 5 is provided with a terminal 7, and the inside of the cable protection shell 5 is provided with a sealing device 4, and the sealing device 4 is closely attached to the On the inner wall of the cable protection case 5, a chuck 6 is provided in the middle of the cable protection case 5, the chuck 6 is inlaid with the cable protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com