Auxiliary hanger for hanging wire and hanging method thereof

A hanger and wire hanging technology, which is applied in the direction of cable suspension device, grounding wire configuration, electrical components, etc., can solve the problem of unsatisfactory hanging wire effect, reduce the risk of falling off, reduce self-weight, and increase friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

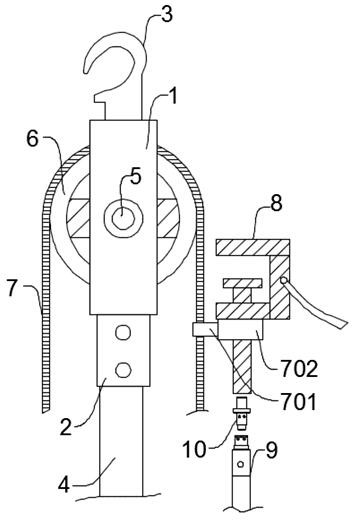

[0038] refer to figure 1 As shown, one embodiment of the present invention is, a kind of auxiliary hanger that is used for hanging wire, comprises carrier 1, and wherein carrier 1 is existing alloy, and above-mentioned carrier 1 bottom is provided with installation tube 2, and above-mentioned carrier 1 top is provided with The hook 3, the lower end of the installation tube 2 is connected to the first operating rod 4, which is used to drive the carrier 1 to move by the first operating rod 4, and is used to hang on the cable by the hook 3, wherein the position where the hook 3 hangs on the cable is a grounding clamp 8 Near the position where the line is hung, since the hook 3 itself is connected to the first operating rod 4, the hanging position of the hook 3 can be easily adjusted through the first operating rod 4.

[0039] The installation pipe 2 is a hollow pipe fixed at the lower end of the carrier 1, wherein the first operating rod 4 needs to be in contact with the operator...

Embodiment 2

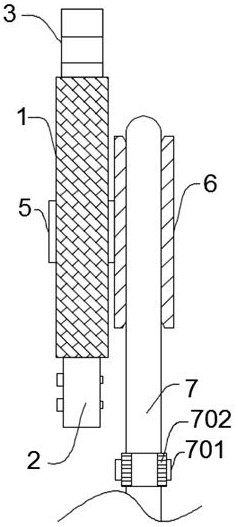

[0045] Based on the above examples, refer to figure 2 As shown, another embodiment of the present invention is that a lock 701 is installed on the above-mentioned traction rope 7, and a hook 702 is installed on the above-mentioned lock 701, which is used to suspend the grounding wire clip 8 by the hanger 702, and is used to hang the ground wire clamp 8 by the hook 702, and is used to hang the ground wire clamp 8 by the pull rope 7. The hook 702 is driven to move, and the hook 702 is used to drive the grounding clamp 8 to move.

[0046] Wherein lock 701 is existing lock, by lock 701, hanging buckle 702 is locked on the traction rope 7, thereby hanging buckle 702 can move along with traction rope 7, and hanging buckle 702 is existing commodity simultaneously, mainly It is to temporarily fix the grounding wire clamp 8, and the locking forms of the grounding wire clamp 8 and the hanging buckle 702 are various:

[0047] For example, the hanging buckle 702 and the grounding wire c...

Embodiment 3

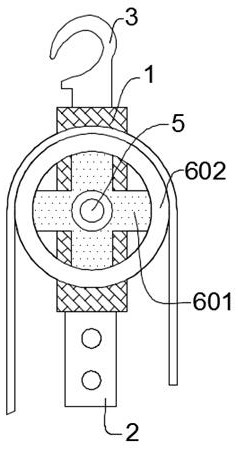

[0050] Based on the above examples, refer to image 3 As shown, another embodiment of the present invention is that the above-mentioned fixed pulley 6 includes a frame body 601, wherein the frame body 601 is connected to the movable end of the bearing of the rotating support 5, and the outer wall of the above-mentioned frame body 601 is sleeved with a wheel ring 602, and the frame body 601 Supporting the wheel ring 602, the force transmitted to the wheel ring 602 by the traction rope 7 can be transmitted to the hook 3 by the frame body 601, thereby providing support through the hook 3 to ensure that the wheel ring 602 rotates stably on the rotating support 5.

[0051] The outer wall of the above-mentioned wheel ring 602 is provided with a groove 603, and the above-mentioned groove 603 is adapted to the traction rope 7. Usually, the depth of the groove 603 is greater than the radius of the traction rope 7, so that when the groove 603 is in contact with the traction rope 7, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com