A method for obtaining the thickness distribution rate of acoustic package components

A thickness distribution, acoustic package technology, applied in geometric CAD, design optimization/simulation, sustainable transportation, etc., can solve the problems of inability to guarantee measurement accuracy, time-consuming, low acquisition efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

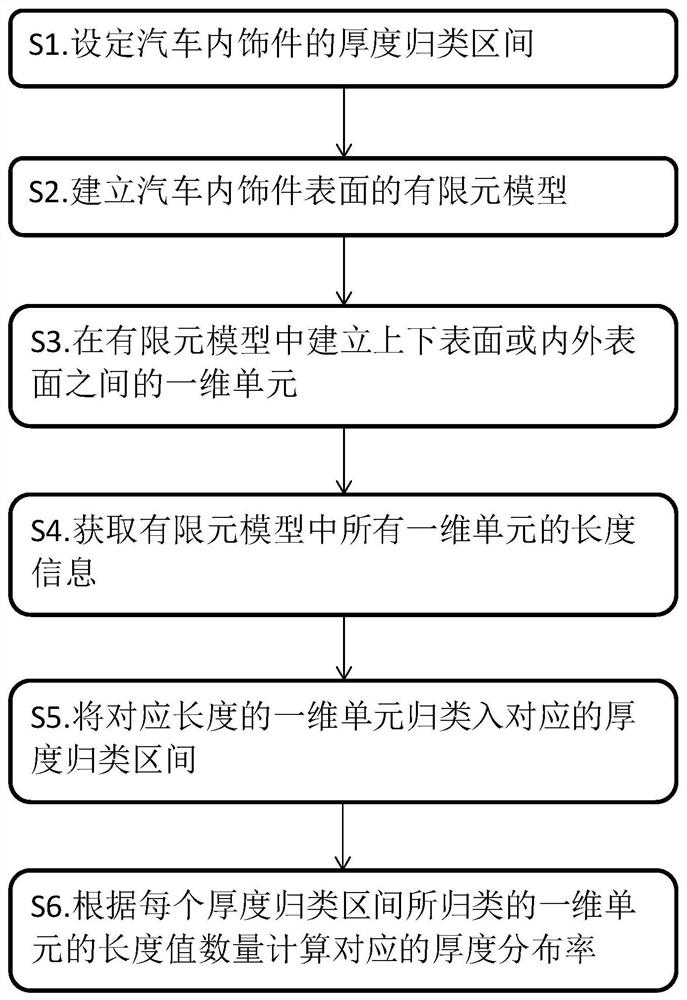

Method used

Image

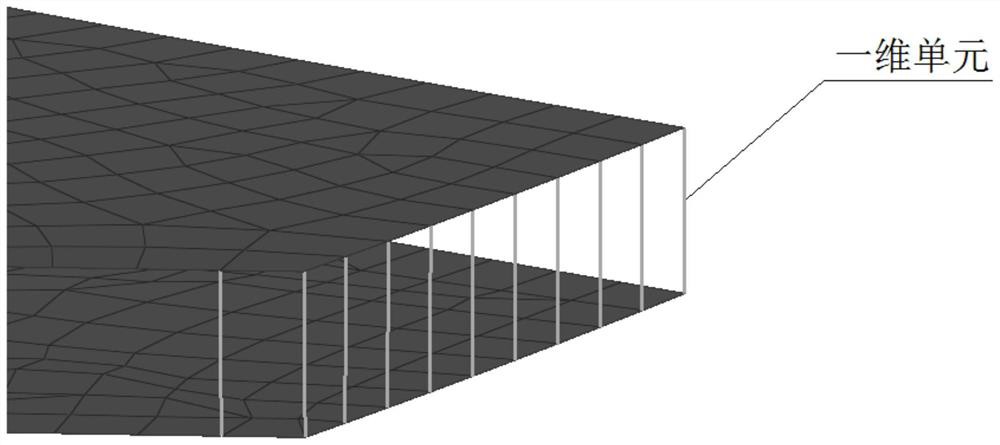

Examples

Embodiment 2

[0086] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 lies in that steps S1, S5, and S6 are different, and this embodiment mainly explains these differences, which are correspondingly represented by steps S1', S5', and S6'. This embodiment also takes the same automotive interior part of Embodiment 1 as an example.

[0087] S1'. Set the thickness classification value of the automotive interior parts.

[0088] This step specifically includes:

[0089] S11. Acquiring the minimum thickness H of the automotive interior parts MIN and maximum thickness H MAX ;

[0090] S12'. At the minimum thickness H MIN and the maximum thickness H MAX A value is selected at the preset difference interval Y to obtain a plurality of thickness classification values P1, P2...Pn, where n is the number of the thickness classification values.

[0091] X=3, then the thickness classification values of P1, P2...P6 in this embodiment are 0, 3, 6, 9, 12, and 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com