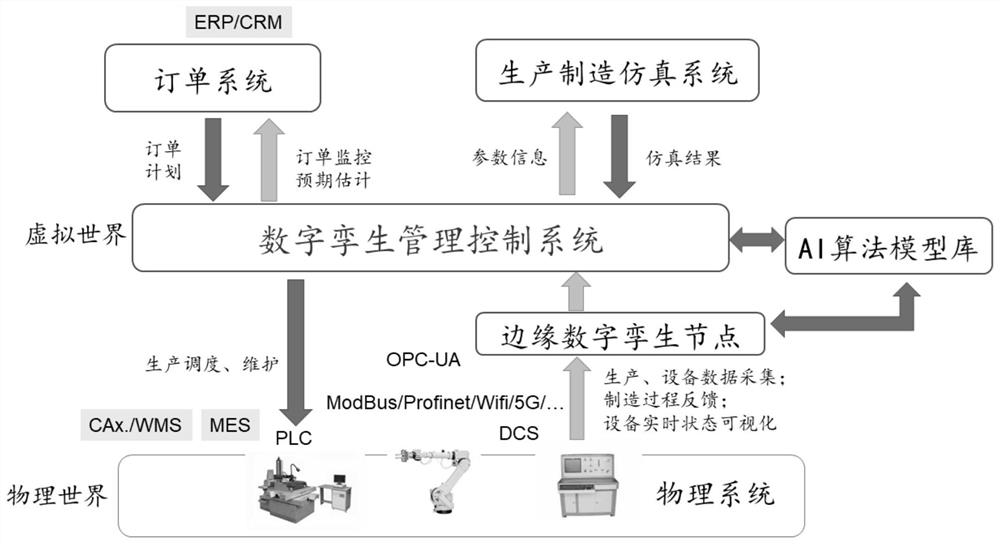

Intelligent production system and method based on edge calculation and digital twinning

A digital and twin technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as difficulty in taking into account the real-time and information integrity of digital entities and physical entities, information loss, etc., to reduce the computational burden , the effect of reducing storage pressure and reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

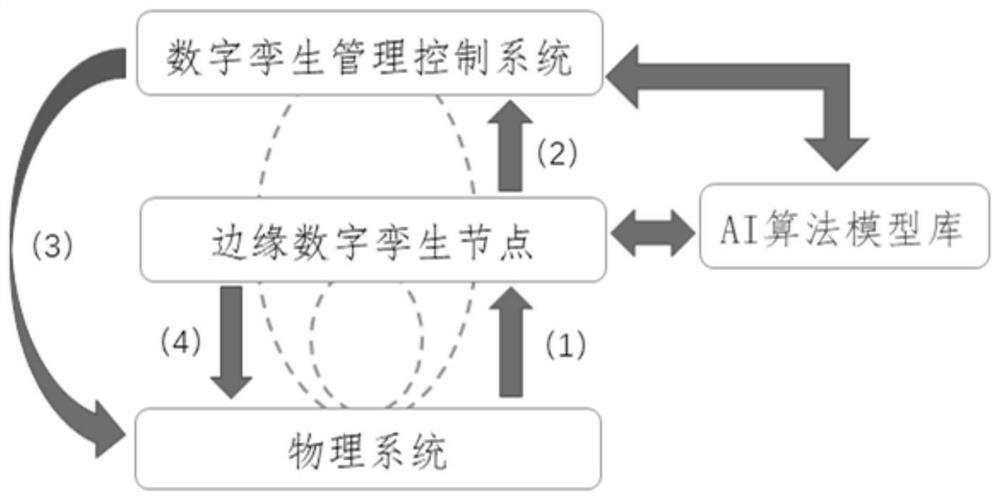

[0067] Embodiment 1, using the intelligent production system based on edge computing and digital twins of the present invention, scheduling production according to the order plan, a process implemented is as follows Figure 4 As shown, it is divided into the following 12 steps to illustrate.

[0068] Step a1, the order system issues the order plan to the digital twin management control system;

[0069] Step a2. The digital twin management control system generates a digital twin model of the physical system based on the historical operating status data of the production line and the current operating status data of the production line. Under the guidance of the production equipment scheduling optimization model in the AI algorithm model library, combined with the target operating status data of the production line, the production Initial resource allocation plan and simulation analysis;

[0070] Step a3, the digital twin management control system assigns the simulation analy...

Embodiment 2

[0080] Embodiment 2. The intelligent production system based on edge computing and digital twins of the present invention performs equipment pre-maintenance process, such as Figure 5 Shown, the following six steps to illustrate.

[0081] Step b1. During the production process, the physical system obtains the physical production line information with the help of intelligent sensing equipment and transmits it to the edge digital twin node through the industrial control network;

[0082] Step b2, the data processing module of the edge digital twin node cleans, aggregates, self-updates, and time series stitches the information of the physical production line and stores it in the memory;

[0083] Step b3, the calculation module of the edge digital twin node invokes specific intelligent models from the AI algorithm model library, such as the production equipment failure prediction model and the life prediction model of key equipment, to analyze and process the data of the physica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com