A high-temperature melting harmless treatment process for waste incineration fly ash

A technology for waste incineration fly ash and harmless treatment, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of restricting the harmless treatment of waste fly ash, high content of volatile elements, and high construction and operation costs. Achieve the effect of saving single incineration time, uniform density and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Ratio of test materials:

[0037] materials Garbage fly ash glass powder Slaked lime Biochar total FFH-180710-1 50 15 20 15 100%

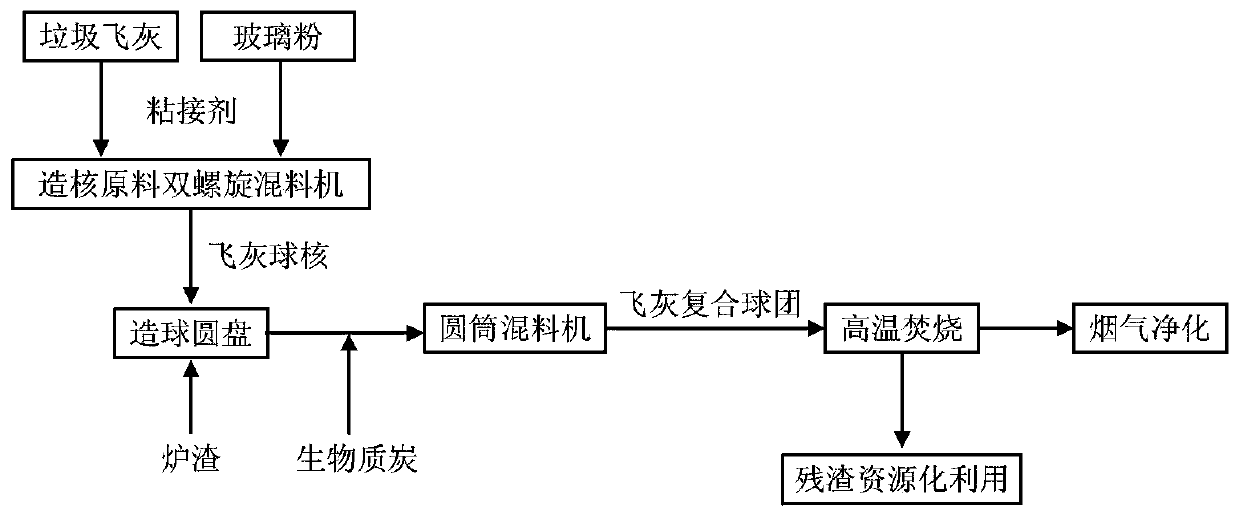

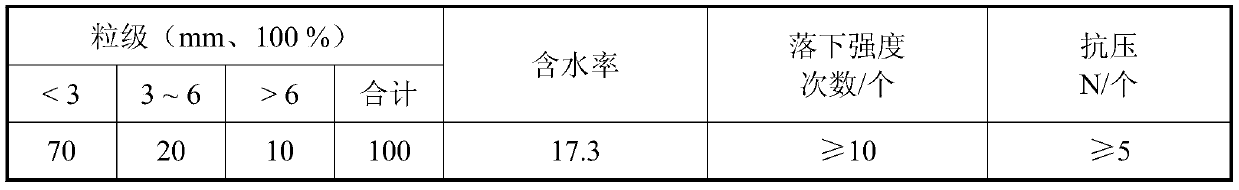

[0038] The harmless treatment process includes the following steps: preparing garbage fly ash and glass powder under the action of a binder to form a fly ash ball core with a particle size of 3-6mm; and testing the physical performance indicators

[0039]

[0040] (2) Under the action of the binder, add slaked lime to the fly ash spherical core to coat the surface of the fly ash spherical core to obtain a fly ash composite pellet. The physical properties of the composite pellet are shown in the following table.

[0041] (3) Directly mix the fly ash composite pellets with the biomass charcoal evenly to obtain a mixture, wherein, after the preparation of the fly ash composite pellets is completed, a certain number of pellets are randomly selected to detect their moisture content and physical properties;

...

Embodiment 2

[0053] Ratio of test materials:

[0054] materials fly ash glass powder Slag Biochar total FFH-180710-2 50 20 15 15 100%

[0055] Harmless treatment process, said process comprises the following steps:

[0056] (1) preparing garbage fly ash and glass powder into fly ash spherical cores with a particle size of 3 to 6 mm under the action of a binder;

[0057]

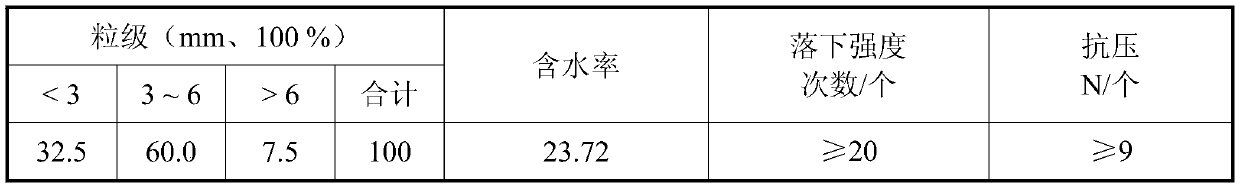

[0058] (2) Under the action of the binder, add slag to the fly ash core to coat the surface of the fly ash core to obtain fly ash composite pellets. The physical properties of the composite pellets are shown in the following table.

[0059] (3) Directly mix the fly ash composite pellets with the biomass charcoal evenly to obtain a mixture, wherein, after the preparation of the fly ash composite pellets is completed, a certain number of pellets are randomly selected to detect their moisture content and physical properties;

[0060] The physical properties of fly ash composite pellets ...

Embodiment 3

[0072] Ratio of test materials:

[0073] materials Garbage fly ash glass powder Slaked lime Biochar total FFH-180730-1 60 18 10 12 100%

[0074] The same processing steps as in the examples were used for processing. The incinerated materials are tested by a third-party testing agency and meet national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com