A Harmless Treatment Process for Garbage Fly Ash

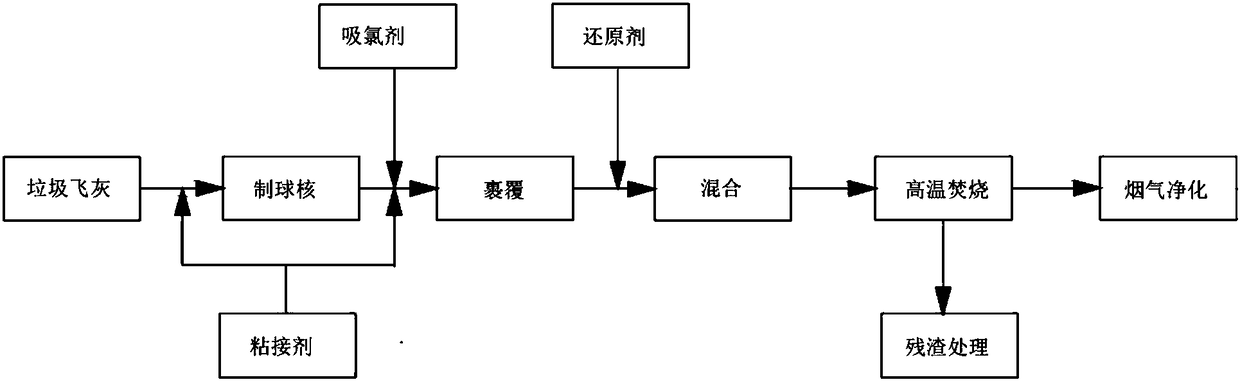

A technology of harmless treatment and garbage fly ash, which is applied in the direction of combustion product treatment, incinerator, emission prevention, etc. It can solve the problems of unfavorable time and space saving, high content of volatile elements, and large equipment footprint. Achieve the effect of saving single incineration time, uniform density and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

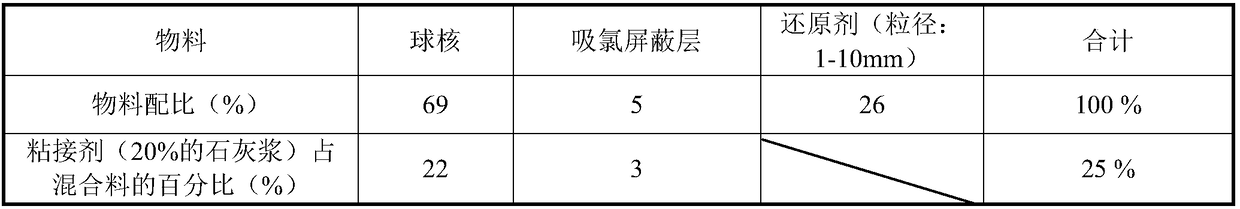

[0036] Ratio of test materials:

[0037]

[0038] A kind of harmless treatment process of garbage fly ash, said process comprises the following steps:

[0039] (1) Preparation of garbage fly ash under the action of a binder into a fly ash ball core with a particle size of 1 to 8 mm;

[0040] (2) Under the action of the adhesive, wrap the chlorine absorbing agent containing calcium oxide on the surface of the fly ash pellet core to form a 0.5-2mm chlorine absorbing shielding layer to obtain chlorine shielding pellets. For the physical properties of chlorine shielding pellets, see Table 1.

[0041] (3) Mix the chlorine-shielding pellets with the biomass charcoal with a moisture content of less than 5% and a particle size of 1-10 mm to obtain a mixture, wherein, after the preparation of the chlorine-shielding pellets is completed, a certain amount of pellets is randomly weighed Detect its water content and physical properties;

[0042] Table 1. The physical properties of chlo...

Embodiment 2

[0055] Ratio of test materials:

[0056]

[0057] A kind of harmless treatment process of garbage fly ash, said process comprises the following steps:

[0058] (1) Preparation of garbage fly ash under the action of a binder into a fly ash ball core with a particle size of 1 to 8 mm;

[0059] (2) Under the action of the adhesive, wrap the chlorine absorbing agent containing calcium oxide on the surface of the fly ash pellet core to form a 0.5-2mm chlorine absorbing shielding layer to obtain chlorine shielding pellets. For the physical properties of chlorine shielding pellets, see Table 2.

[0060] (3) Mix the chlorine-shielding pellets with the biomass charcoal with a moisture content of less than 5% and a particle size of 1-10 mm to obtain a mixture, wherein, after the preparation of the chlorine-shielding pellets is completed, a certain amount of pellets is randomly weighed Detect its water content and physical properties;

[0061] Table 2. The physical properties of ch...

Embodiment 3

[0073] Ratio of test materials:

[0074]

[0075] A kind of harmless treatment process of garbage fly ash, said process comprises the following steps:

[0076] (1) Preparation of garbage fly ash under the action of a binder into a fly ash ball core with a particle size of 1 to 8 mm;

[0077] (2) Under the action of the adhesive, wrap the chlorine absorbing agent containing calcium oxide on the surface of the fly ash pellet core to form a 0.5-2mm chlorine absorbing shielding layer to obtain chlorine shielding pellets. For the physical properties of chlorine shielding pellets, see table 3.

[0078] (3) Mix the chlorine-shielding pellets with the biomass charcoal with a moisture content of less than 5% and a particle size of 1-10 mm to obtain a mixture, wherein, after the preparation of the chlorine-shielding pellets is completed, a certain amount of pellets is randomly weighed Detect its water content and physical properties;

[0079] Table 3. The physical properties of ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com