Intelligent environment-friendly mercury injection rock core treatment device

An environmental protection treatment and core technology, applied in the field of environmental protection, can solve problems such as the unimaginable degree of secondary disasters, the need to hinder the smooth development, and the leakage of mercury-containing pollutants, so as to improve the efficiency of condensation and separation, ensure environmental protection standards, and increase the number of trays. number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

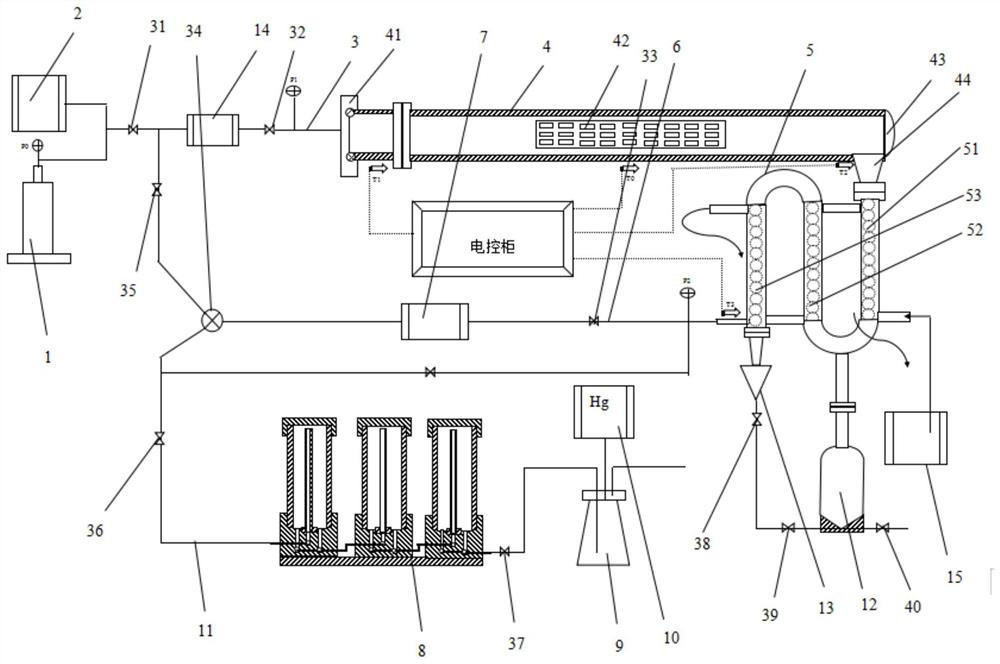

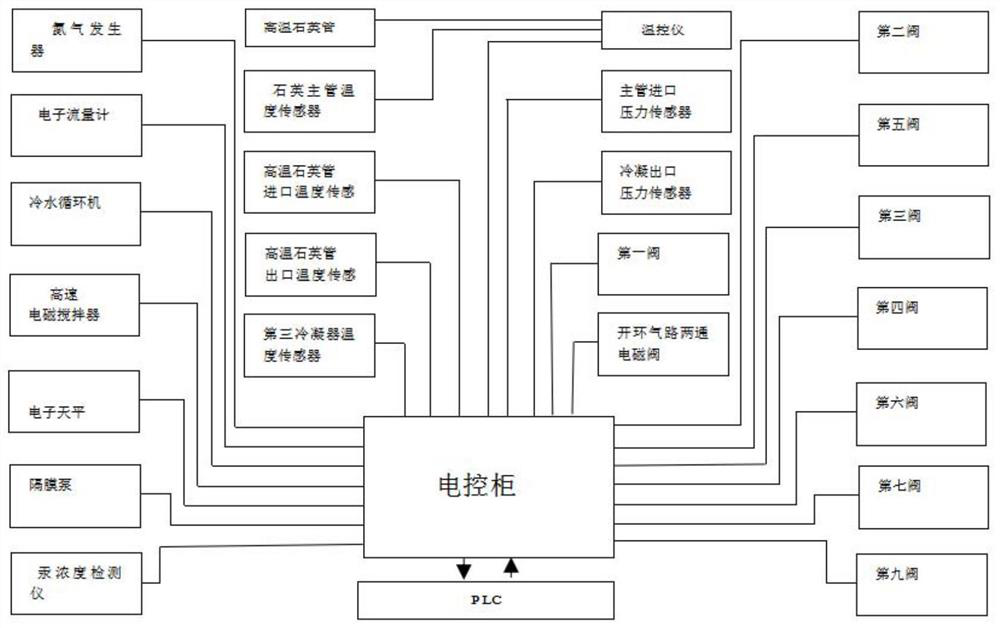

[0022] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0023] Such as figure 1 As shown: the present invention provides a mercury injection core intelligent environmental protection processing device, wherein: comprising a gas cylinder 1, the gas cylinder 1 is connected to a nitrogen generator 2, and the nitrogen generator 2 is sequentially connected to a high-temperature quartz through a first pipeline 3 Tube 4 and condenser 5, the output end of said condenser 5 is respectively connected to collecting bottle and high-temperature quartz tube 4, and said condenser 5 and high-temperature quartz tube 4 are connected through second pipeline 6, and said second pipeline 6 is provided with Diaphragm pump 7, described diaphragm pump 7 is respectively connected with high temperature quartz tube 4 and purifier 8, and described purifier 8 is connected with absorption bottle 9, and described absorption bottle 9 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com