Device for detecting pseudo soldering of power battery module and detection method thereof

A power battery and module technology, applied in measuring devices, electrical connection testing, electrical measurement, etc., can solve the problems of CCD scan failure, weakened welding strength of connecting components and batteries, consistency, and EMC interference affecting the accuracy of single voltage Accurate measurement value and stable voltage can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

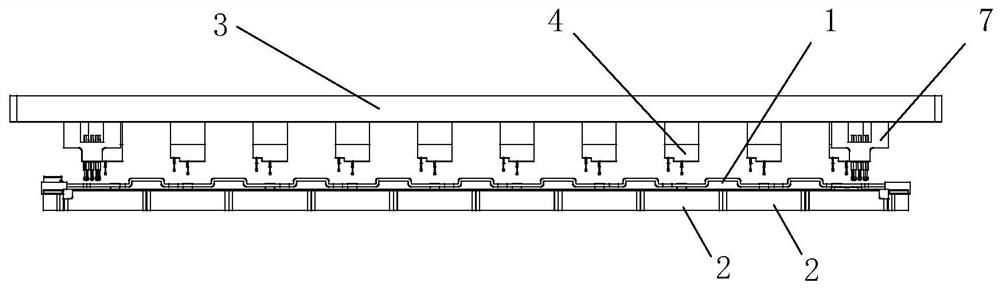

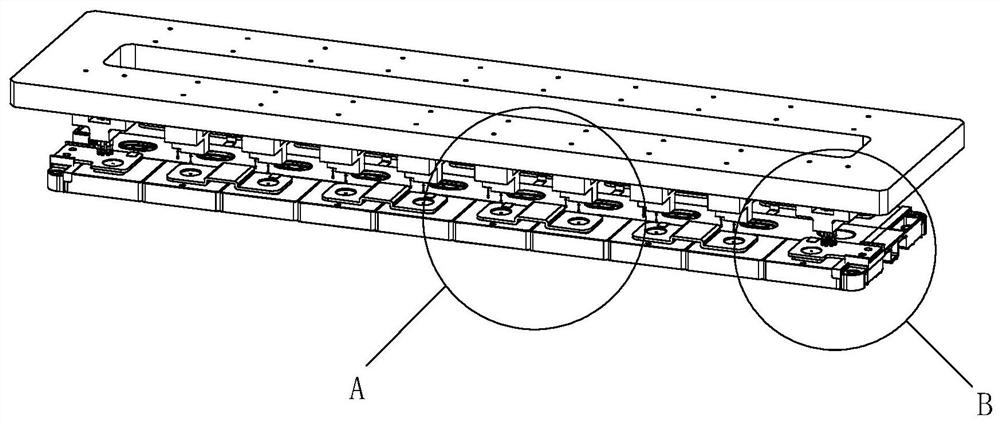

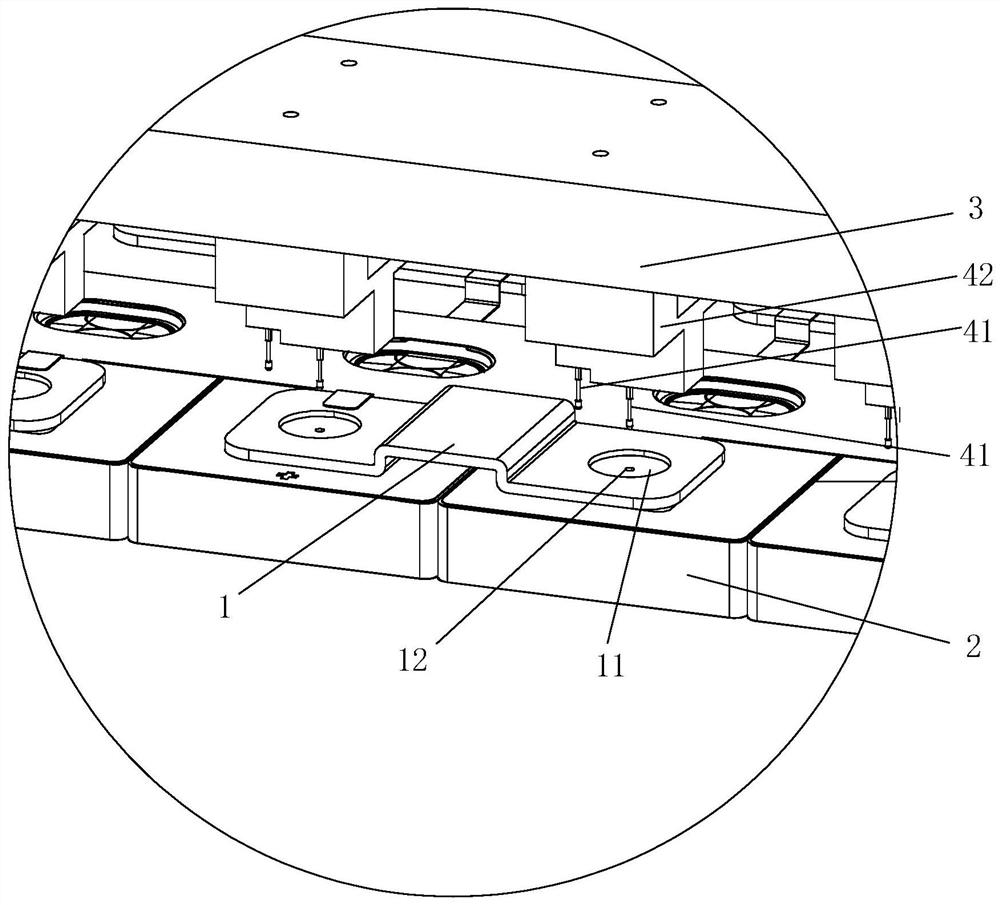

[0053] Such as figure 1 with figure 2 As shown, the present embodiment 1 provides a device for detection of false welding of a power battery module, the power battery module includes a plurality of batteries 2 and a plurality of connection assemblies 1, the connection assembly 1 and The poles of the electric core 2 are welded, and the plurality of electric cores 2 are connected in series with positive and negative poles through the connecting assembly 1, and the connecting assembly 1 is formed with a positioning hole 12 that matches the pole;

[0054] The device includes:

[0055] A plurality of detection units 4, corresponding to the number of each connection assembly 1, each detection unit 4 includes two first probes 41;

[0056] The current unit 5 has a current input terminal and a current output terminal, and the current input terminal and the current output terminal are respectively in conductive contact with the two ends of the battery cells 2 connected in series to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com