Solid waste and hazardous waste gasification melting furnace with central gas collection

A technology of gasification melting and melting furnace, which is applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of feed sealing, etc., and achieve the effects of improving the efficiency of gasification and melting, reducing the burden, and preventing deflagration accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

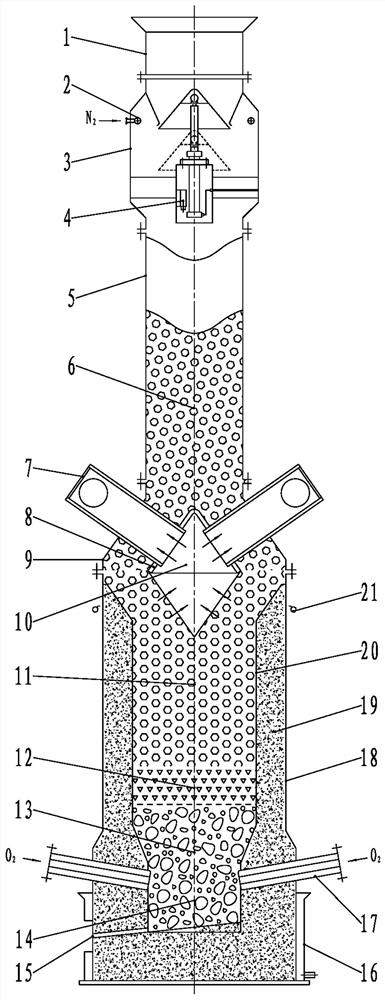

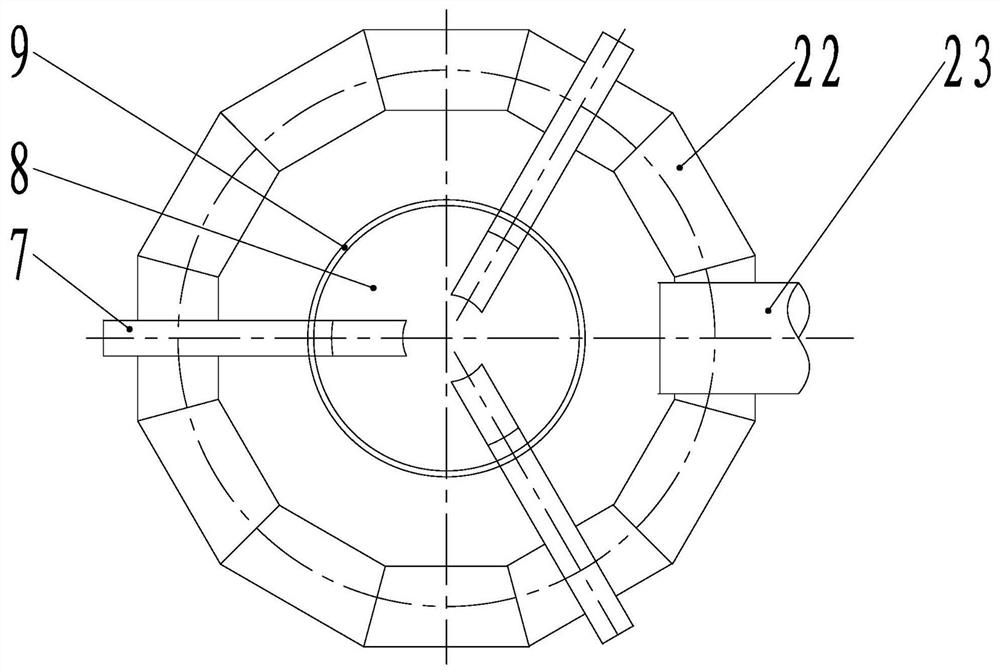

[0026] A solid waste and hazardous waste gasification melting furnace with central gas collection, such as figure 1 and figure 2 Shown: including the furnace top charging system, furnace throat center gas collection device and furnace body gasification and melting part, the furnace top charging system includes a receiving hopper 1 fixedly connected from top to bottom, a sealing valve 3 and a sealing barrel 5. A nitrogen filling pipe 2 is provided on the side wall of the sealing valve 3 , and a level gauge 4 is provided at the lower part of the sealing valve 3 . The central gas collection device of the furnace throat includes a gas guide beam 7, a gas collection bell 8 and a furnace throat shell 9, the furnace throat shell 9 is a conical cylinder, the upper port is connected with the sealing barrel 5, and the lower port is connected with the furnace shell 18 Connection; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com