Fireproof coating structure for building pipeline

A technology of cladding structure and fireproof package, which is applied in pipeline damage/abrasion prevention, pipeline protection, pipeline layout, etc. It can solve the problems of difficult construction, high installation risk factor, poor earthquake resistance, etc., and meet the specifications of installation tools and accessories less, strong standardization and versatility, and low on-site space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: A kind of building pipe fire protection cladding structure

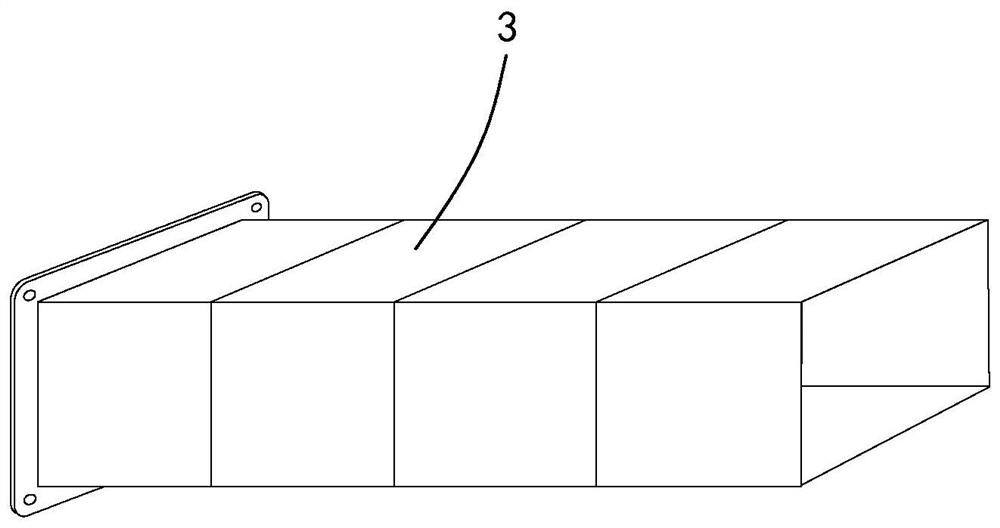

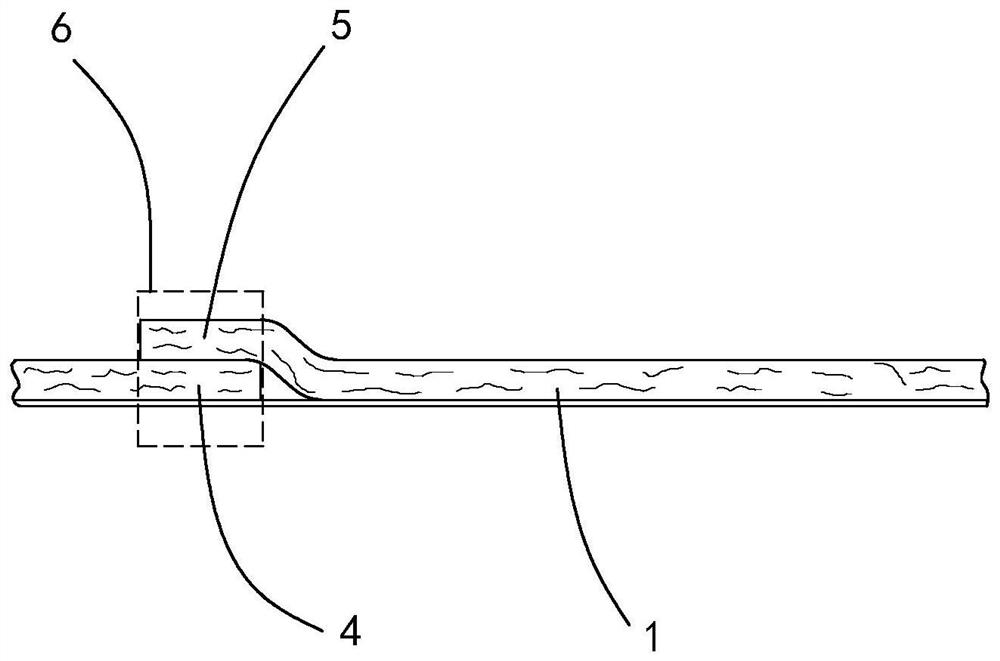

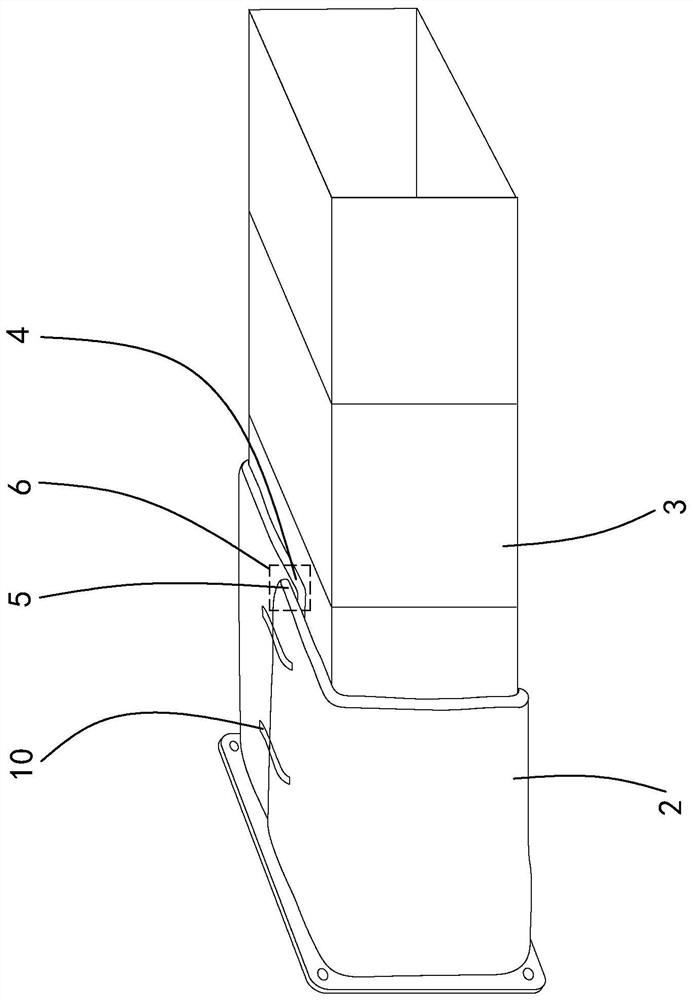

[0033] Please refer to the attached figure 1 to attach Image 6 , a fireproof coating structure for building pipelines, the coating structure is made of flexible materials, the main body of the coating structure 1 is composed of a plurality of coating units 2, and the plurality of coating units 2 are sequentially arranged linearly along the pipeline 3 axis. The cladding unit 2 is made of a rectangular fireproof composite material sheet that surrounds the pipeline 3 and covers the pipeline 3 axially and tightly on the outer periphery of the pipeline 3 . The rectangular fireproof composite material sheet is composed of a fiber core blanket and an aluminum foil fiber composite facing material, and the aluminum foil fiber composite facing material is wrapped on the outside of the fiber core blanket. The fiber core blanket is an inorganic fiber blanket whose main components include calcium, silicon ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com