Half-hole spunlace non-woven cloth and preparation method thereof

A spunlace non-woven, semi-perforated technology, used in non-woven fabrics, textiles and papermaking, etc., can solve the problems of low water absorption, rough surface, weak grip, etc., to achieve a good thick feeling, good suction The effect of liquid, good water conductivity and water storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

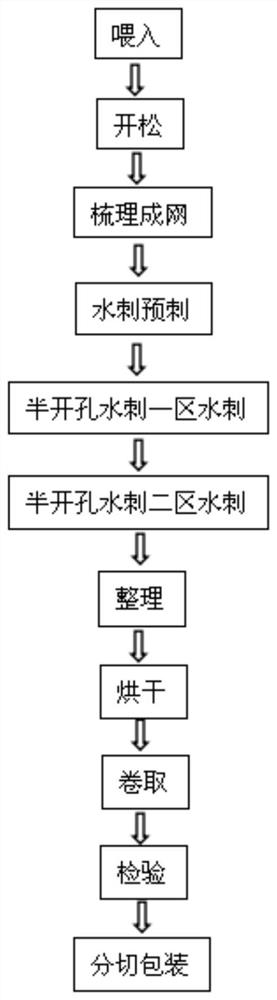

[0033] like image 3 As shown, the present invention also provides a method for preparing the above-mentioned semi-open spunlace nonwoven fabric, comprising the following steps:

[0034] 1) Feeding, opening and combing the fibers into a web;

[0035] 2) Spunlace pre-stabbing, half-opening first-zone spunlace, half-opening second-zone spunlace;

[0036] 3) Arrangement, drying, coiling, inspection, slitting and packaging.

[0037] Wherein, in step 2), the setting condition of the first zone of the semi-apertured spunlace is 3-5 spunlace heads for spunlace entanglement, and the spunlace pressure is 30-120bar; The fixed condition is that 1-2 spunlace heads are spunlace entangled, and the spunlace pressure is 10-20bar; the forming net in the first area of the semi-open spunlace is a spunlace forming mesh curtain with more than 60 mesh; The forming mesh in the second area of the spunlace is 24-40 mesh spunlace forming mesh curtain; the first area with half holes is mainly to ...

Embodiment 1

[0040] like image 3 As shown, this embodiment provides a method for preparing a semi-open spunlace nonwoven fabric, comprising the following steps:

[0041] Raw material preparation: use 1.5D viscose fiber, the mass percentage is 50%; 1.4D polyester fiber, the mass percentage is 50%, and the product weight is set to 50g / ㎡.

[0042] Feeding, opening, and carding of fibers into a web: feed the raw materials into the open feeder according to the above ratio for opening and mixing, and initially open the fiber agglomerates into fiber bundles. After opening and mixing evenly, it is transported to the carding machine. The carding machine further combs the fiber bundles into single fibers, then passes through the messy rollers, and finally passes through the doffer to form a fiber web and spread it on the conveyor curtain to be transported to the next process.

[0043] Spunlace pre-stabbing, semi-open spunlace one-zone spunlace, semi-open-hole spunlace two-zone spunlace: pre-punctu...

Embodiment 2

[0046] like image 3 As shown, this embodiment provides a method for preparing a semi-open spunlace nonwoven fabric, comprising the following steps:

[0047] Raw material preparation: 1.5% viscose fiber is used, and the mass percentage is 70%. 1. 4D polyester fiber, the mass percentage is 30%, and the product weight is set at 55g / ㎡.

[0048] Feeding, opening, and carding of fibers into a web: feed the raw materials into the open feeder according to the above ratio for opening and mixing, and initially open the fiber agglomerates into fiber bundles. After opening and mixing evenly, it is transported to the carding machine. The carding machine further combs the fiber bundles into single fibers, then passes through the messy rollers, and finally passes through the doffer to form a fiber web and spread it on the conveyor curtain to be transported to the next process.

[0049] Spunlace pre-stabbing, semi-open spunlace one-zone spunlace, semi-open-hole spunlace two-zone spunlace: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com