Biodegradable material as well as raw material composition, preparation method and application thereof

A technology of biodegradable materials and raw material compositions, which is applied in the fields of application, devices for catching or killing insects, animal husbandry, etc., and can solve the problem that the biomass material hemicellulose is not widely used, the cost is high, and the insect traps are not widely used. Raw materials are not easy to degrade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

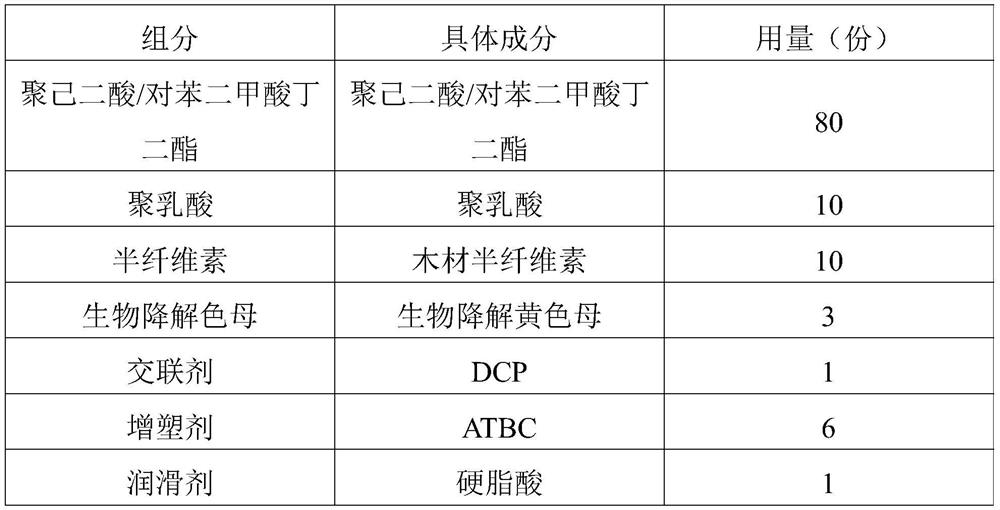

Embodiment 1

[0072] Preparation of wood hemicellulose: take 250g of wood, wash it, crush it, cook it at 135°C for 30min, filter, and collect the filter residue; use 500g of NaOH aqueous solution with a concentration of 10g / dL to extract the obtained filter residue, and the extraction temperature is 80°C , the leaching time is 2h, filter after leaching, take the filtrate, neutralize the pH of the filtrate to 7 with 6mol / L hydrochloric acid, and centrifuge for 20min at a speed of 3000r / min to obtain precipitate A; Soak in 95% ethanol water solution by volume, and centrifuge for 20 minutes at a speed of 3000 r / min to obtain a muddy sediment for later use, that is, wood hemicellulose.

[0073] The raw material composition of the biodegradable material is added into a high-speed mixer for mixing, then added into a parallel twin-screw extruder, extruded and granulated to obtain the biodegradable material. The temperatures of the parallel twin-screw extruder from zone one to zone six are 180°C, 1...

Embodiment 2

[0078] Preparation of wood hemicellulose: take 250g of wood, wash it, crush it, cook it at 135°C for 30min, filter, and collect the filter residue; use 500g of NaOH aqueous solution with a concentration of 10g / dL to extract the obtained filter residue, and the extraction temperature is 80°C , the leaching time is 2h, filter after leaching, take the filtrate, neutralize the pH of the filtrate to 7 with 6mol / L hydrochloric acid, and centrifuge for 20min at a speed of 3000r / min to obtain precipitate A; Soak in 95% ethanol water solution by volume, and centrifuge for 20 minutes at a speed of 3000 r / min to obtain a muddy sediment for later use, that is, wood hemicellulose.

[0079] The raw material composition of the biodegradable material is added into a high-speed mixer for mixing, then added into a parallel twin-screw extruder, extruded and granulated to obtain the biodegradable material. The temperatures of the parallel twin-screw extruder from zone one to zone six are 130°C, 1...

Embodiment 3

[0084] Cotton stalk hemicellulose preparation: 250g cotton stalks were washed and crushed, steamed at 135°C for 30min, filtered, and the filter residue was collected; the filter residue was extracted with 500g of NaOH aqueous solution with a concentration of 10g / dL, and the extraction temperature was 80°C, the leaching time is 2h, filter after leaching, take the filtrate, neutralize the pH of the filtrate to 7 with 6mol / L hydrochloric acid, and centrifuge at a speed of 3000r / min for 20min to obtain Precipitate A; Precipitate A Soak in 750g of 95% ethanol water solution by volume, and centrifuge for 20min under the condition of rotating speed of 3000r / min when there is no precipitation, to obtain muddy sediment for later use, namely cotton straw hemicellulose.

[0085]The raw material composition of the biodegradable material is added into a high-speed mixer for mixing, then added into a parallel twin-screw extruder, extruded and granulated to obtain the biodegradable material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com