Safety tongs for elevator and debugging method thereof

A debugging method and safety gear technology, applied in elevators, transportation and packaging, etc., can solve problems such as difficulty in making precise adjustments, cumbersome debugging work, and adjustment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

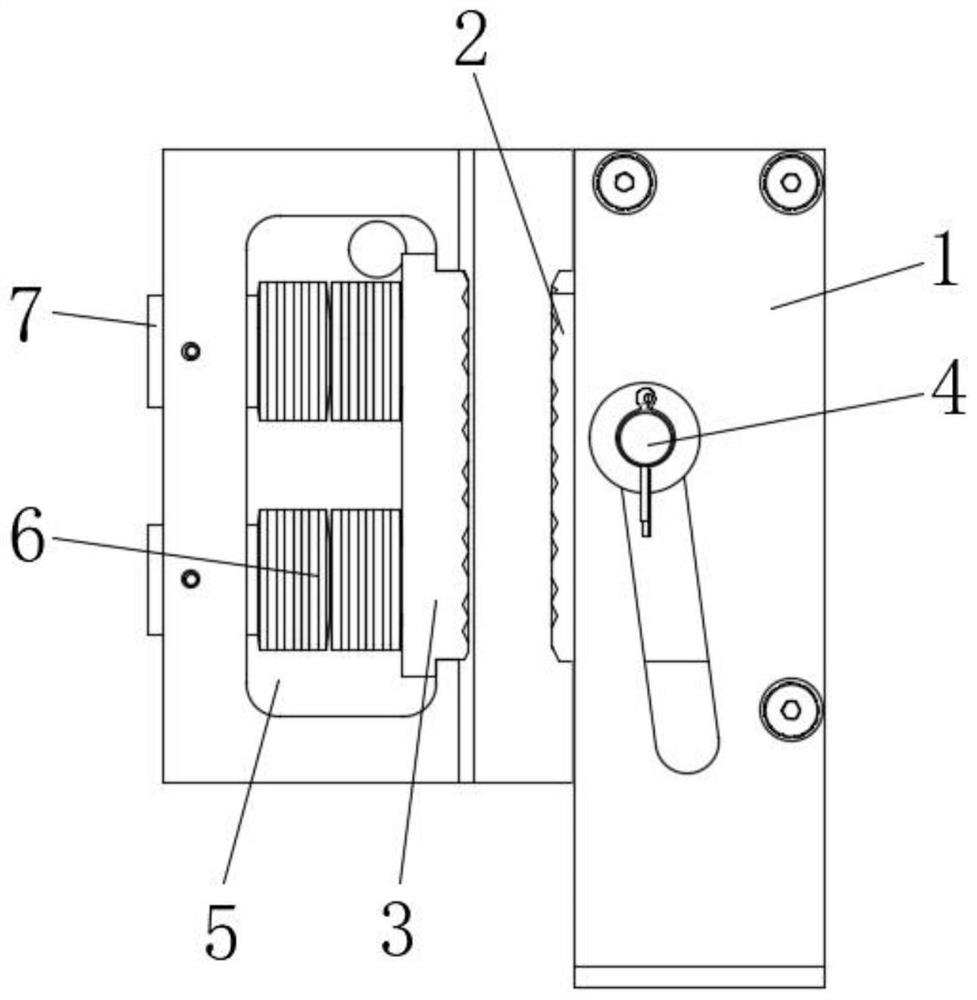

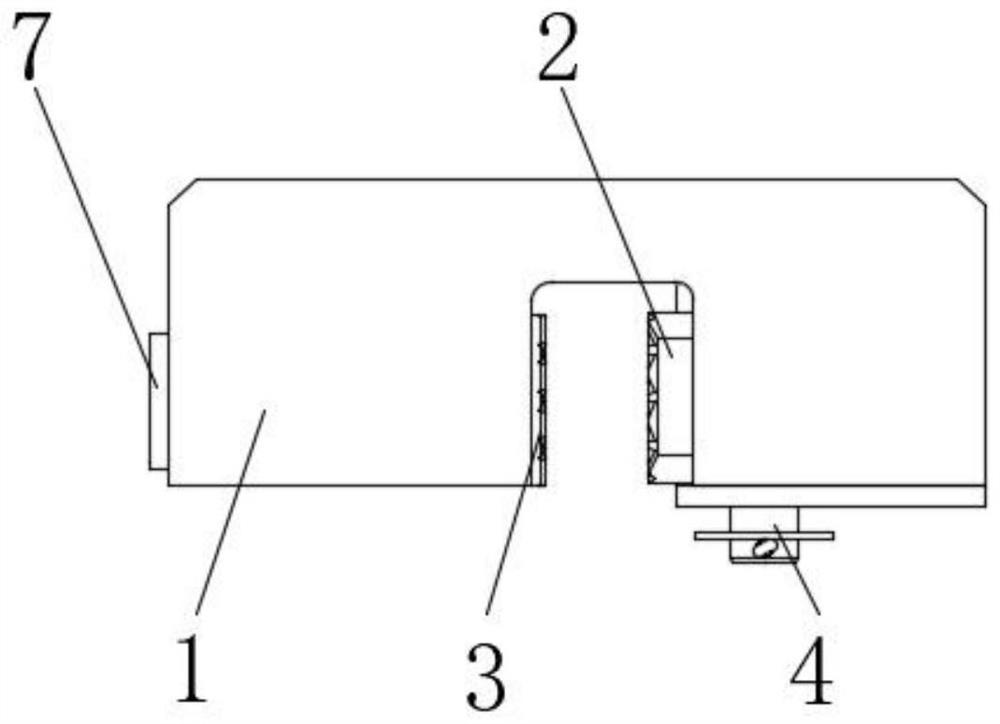

[0042] A kind of debugging method of elevator safety gear, its debugging method comprises the following steps:

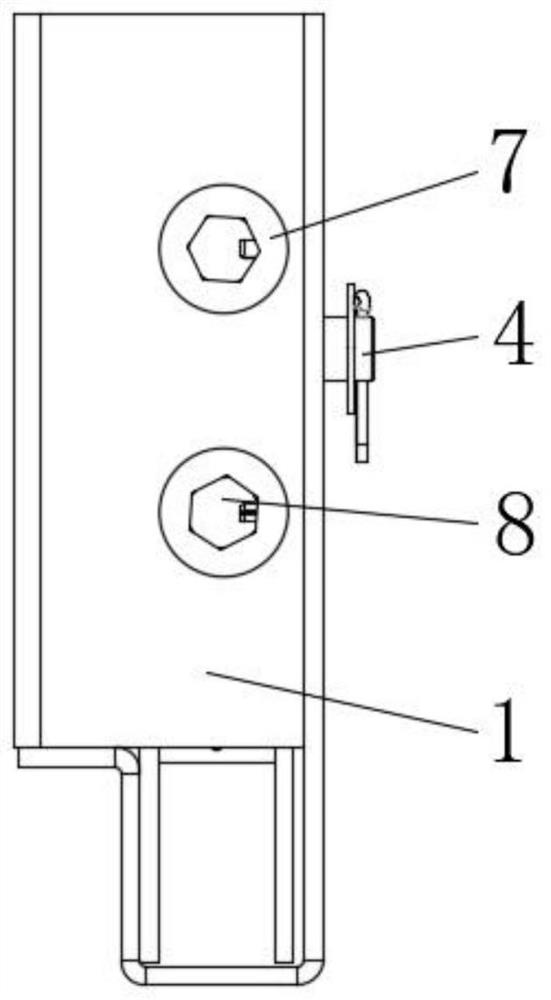

[0043] (1) Preparation: first place the caliper body on the surface of the equipment operating table, and check whether the parts are complete at the same time, then place a gasket between the fixed brake block and the movable brake block, and push the movable brake block along the direction of the slope Assemblies to press the fixed brake block through the gasket. The parts to be inspected include the caliper body, the fixed brake block assembly, the movable fixed brake block assembly, the needle roller assembly and the butterfly spring group;

[0044] (2) Clamp body fixation: place the safety gear inside the equipment, and align the two hexagonal grooves with the two hexagon head studs on the equipment, then open the longitudinal cylinder and press the clamp body, the pressure of the longitudinal cylinder will Less than the strength of the forceps;

[0045] (3) T...

Embodiment 2

[0051] A kind of debugging method of elevator safety gear, its debugging method comprises the following steps:

[0052] (1) Preparation: first place the caliper body on the surface of the equipment operating table, and check whether the parts are complete at the same time, then place a gasket between the fixed brake block and the movable brake block, and push the movable brake block along the direction of the slope Assemblies to press the fixed brake block through the gasket. The parts to be inspected include the caliper body, the fixed brake block assembly, the movable fixed brake block assembly, the needle roller assembly and the butterfly spring group;

[0053] (2) Clamp body fixation: place the safety gear inside the equipment, and align the two hexagonal grooves with the two hexagon head studs on the equipment, then open the longitudinal cylinder and press the clamp body, the pressure of the longitudinal cylinder will Less than the strength of the forceps;

[0054] (3) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com