Auxiliary frame and motor vehicle

A sub-frame and motor vehicle technology, applied in vehicle components, transportation and packaging, substructure, etc., can solve problems such as not satisfying light weight and smoothness, increasing the weight of the reducer, and large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

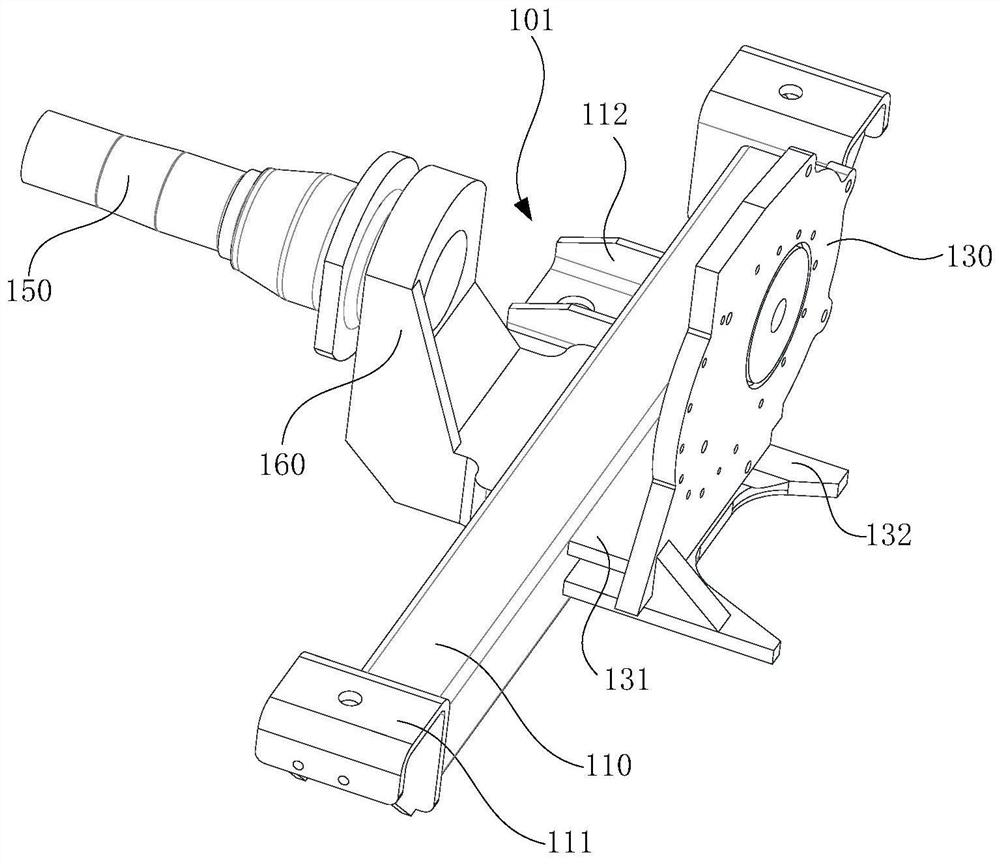

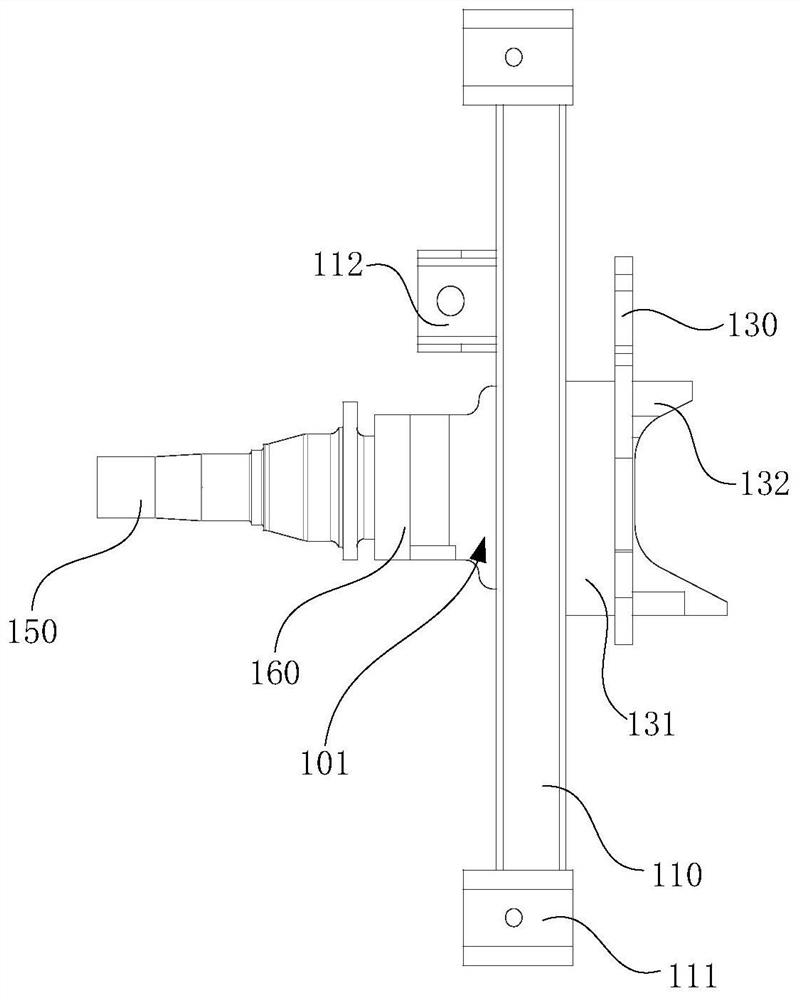

[0028] see figure 1 , which is a schematic structural view of a subframe 100 provided in the first embodiment of the present invention. The subframe 100 includes, for example, two longitudinal beams 110 oppositely arranged, two first cross beams 120, and two mounting brackets. 130 , the second beam 140 , two half-shaft sleeves 150 , and two wheel-side connectors 160 . Wherein, the two first beams 120 are connected between the two longitudinal beams 110 at intervals, the two installation frames 130 are respectively connected to opposite ends of the two first beams 120, and the second beam 140 is connected to the two installation frames 130 The two half shaft sleeves 150 are located on the sides of the two longitudinal beams 110 away from the two first cross beams 120 respectively, and the two wheel side connectors 160 are respectively connected to the two half shafts. Between the bushing 150 and the corresponding longitudinal beam 110 .

[0029] In order to facilitate a clear...

no. 2 example

[0043] The second embodiment of the present invention provides a motor vehicle (not shown in the figure), for example, the motor vehicle includes: a motor vehicle body and the sub-frame 100 as provided in the first embodiment. Wherein, the subframe 100 is installed to the frame of the vehicle body. Wherein, the motor vehicle body may be an existing motor vehicle, that is, the sub-frame 100 may be installed on the frame of an existing motor vehicle.

[0044] Specifically, see Figure 4 , the second mounting position 102 formed between the second beam 140, the two first beams 120 and the two mounting brackets 130 is used to install the wheel drive motor of the vehicle body; the two first mounting positions 101 are respectively used for The wheel drive reducer 170 of the motor vehicle body is installed; the axle sleeve 150 is connected to the wheel of the motor vehicle body. Further, the output shaft of the wheel drive motor is pivotally connected to the input shaft of the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com