Automatic concrete pouring system

A kind of concrete and automatic technology, applied in the direction of supply device, ceramic molding machine, manufacturing tools, etc., can solve the problems of high labor intensity, inability to perform automatic pouring, and large manpower and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

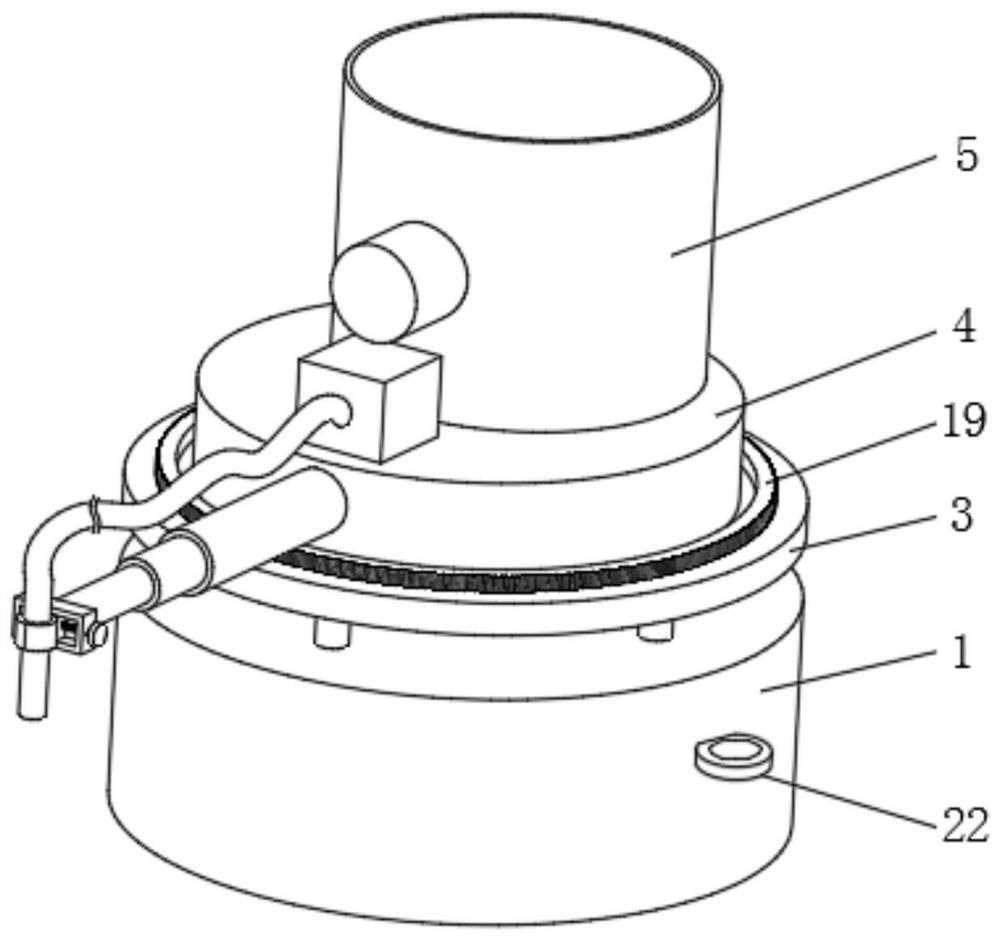

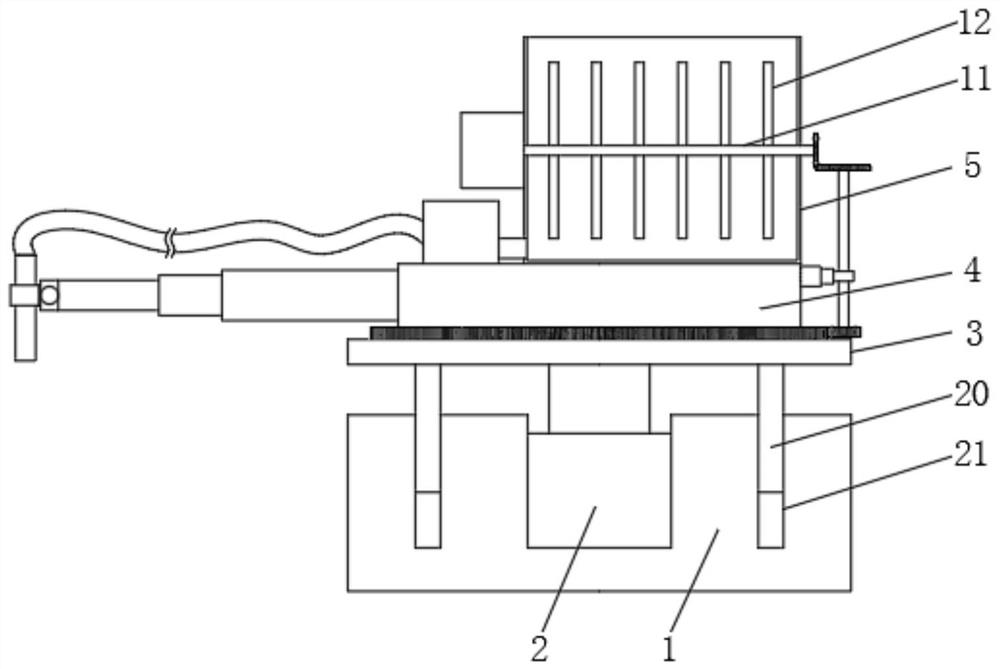

[0034] Example: Reference figure 1 and figure 2 The shown automatic concrete pouring system includes a base 1, and the base 1 can be any base in the prior art, such as a metal base.

[0035] The top of the base 1 is provided with a placement groove, and a lifting hydraulic cylinder 2 is arranged in the placement groove. The lifting hydraulic cylinder 2 can be any hydraulic cylinder in the prior art. In the present invention, the model of the lifting hydraulic cylinder 2 is HOB63.

[0036] The output end of the lifting hydraulic cylinder 2 is drivingly connected with a support platform 3, and the support platform 3 may be any platform in the prior art, such as a circular platform.

[0037] The top of the supporting platform 3 is rotatably connected with a rotary platform 4, and the top of the rotary platform 4 is fixedly connected with an upper opening mixing box 5 and a pouring pump 6, and the mixing box 5 and the pouring pump 6 can be connected to the rotary platform throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com