A fast cooling cutting machine

A cutting machine, fast technology, applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of unable to cool down the main shaft and bearing quickly, poor heat absorption effect, etc., to improve heat dissipation and cooling efficiency, avoid Pollution, the effect of prolonging the practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

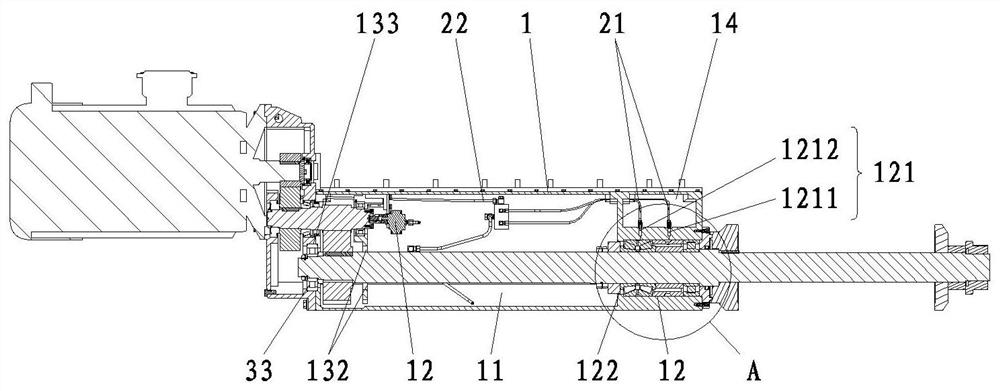

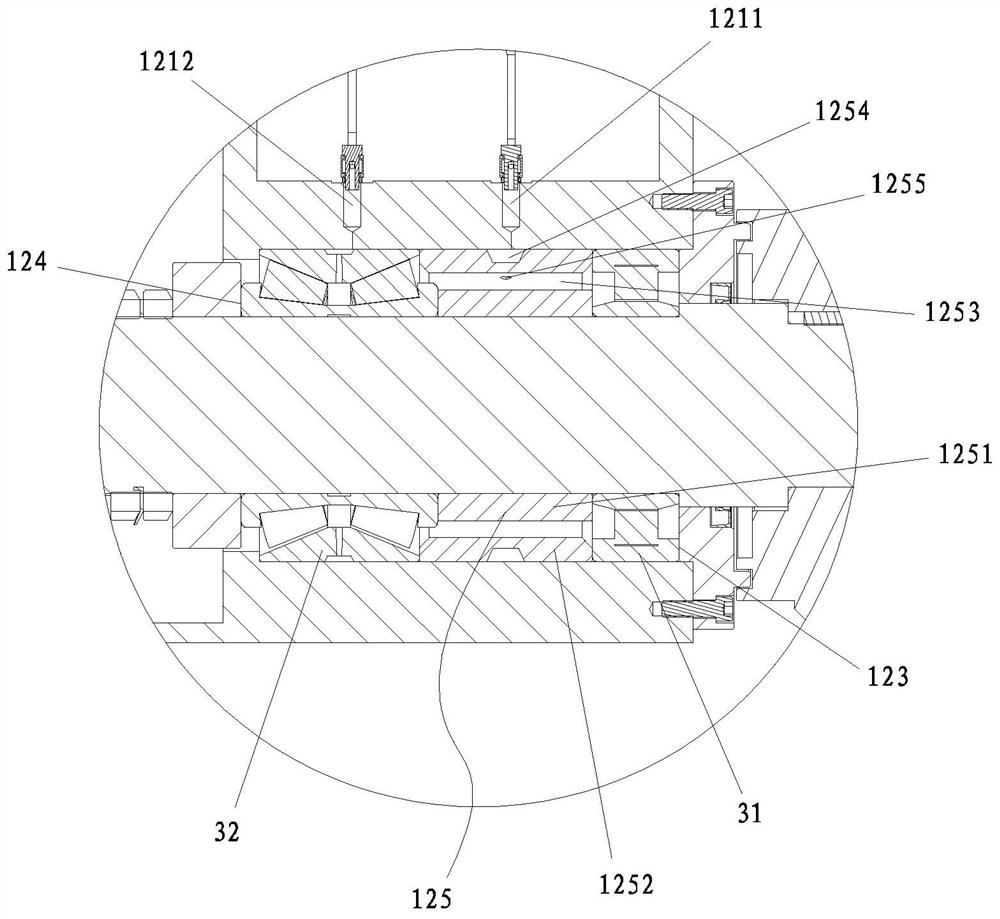

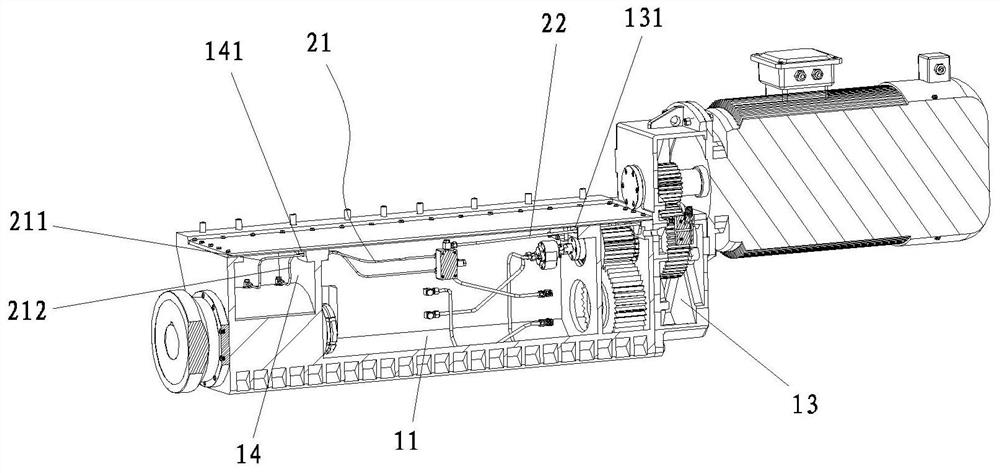

[0046] Such as Figure 1-3 As shown, a cutting machine with rapid heat dissipation includes a main body of the cutting machine, and the main body of the cutting machine includes a headstock 1; wherein, the headstock 1 includes a liquid storage chamber 11 for storing cooling liquid, and a first cooling chamber for cooling the bearing at one end of the main shaft 12, and the second cooling cavity 13 for cooling the bearing at the other end of the main shaft.

[0047] After adopting the above structure, during operation, the liquid storage chamber 11 can be used to store cooling liquid, and the cooling liquid in the liquid storage chamber 11 can contact the main shaft to absorb heat and cool the main shaft. In addition, the spindle box 1 is also provided with a first cooling cavity 12 and a second cooling cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com