Electrochemical deburring machine

A deburring machine, electrochemical technology, applied in electrochemical machining equipment, electric machining equipment, accessories and other directions, can solve the problems of high processing cost and small scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

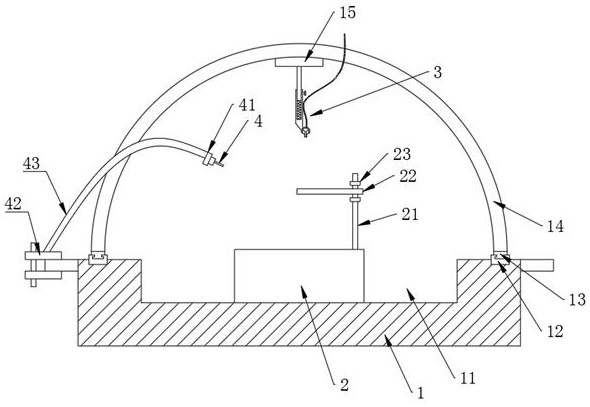

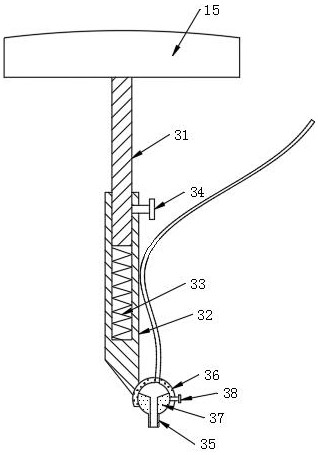

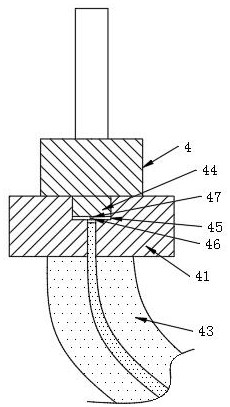

[0031] Embodiment: a kind of electrochemical deburring machine, such as figure 1 As shown, including machine base 1, there is a reflux tank 11 for recovering the electrolyte in the middle of the machine base 1, a workbench 2 for placing workpieces is arranged in the middle of the reflux tank 11, and a clamp for clamping workpieces is arranged on the workbench 2. Fasteners, the return tank 11 is surrounded by a circular turntable 12, two opposite fixed blocks 13 are slidably connected to the turntable 12, and a semicircular rotating frame 14 is erected on the machine base 1, and the two rotating frames 14 The ends are respectively fixed on a fixed block 13, and an arc-shaped moving block 15 is slidably connected to the inner side of the rotating frame 14. The cathode part 4 matched with the workpiece is provided with a fixing mechanism for fixing the cathode part 4 on the base 1 .

[0032] Fix the workpiece on the workbench 2 through the clamping parts, first turn the rotating...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap