A general transposition gear reducer and its reversing method

A technology of gear reducer and gear shaft, which is applied in the direction of gear transmission, belt/chain/gear, application, etc. It can solve the problem that the gear reducer cannot meet the actual needs, the accuracy of machine head type investigation is difficult to guarantee, and the machine head lacks uniformity Standards and other issues, to achieve the effect of simple structure, few types of parts, and common types of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

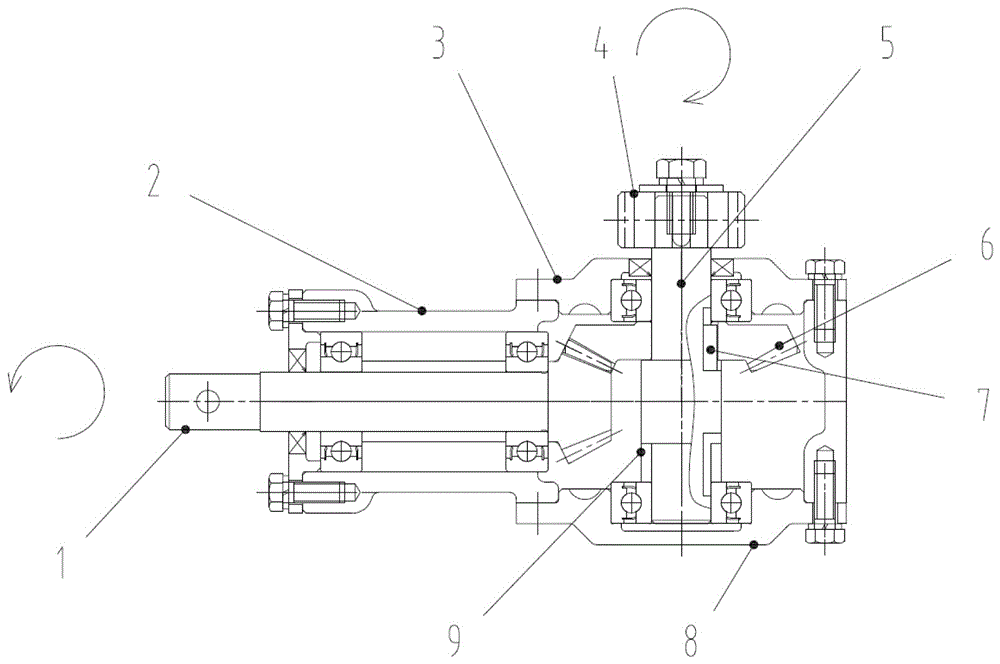

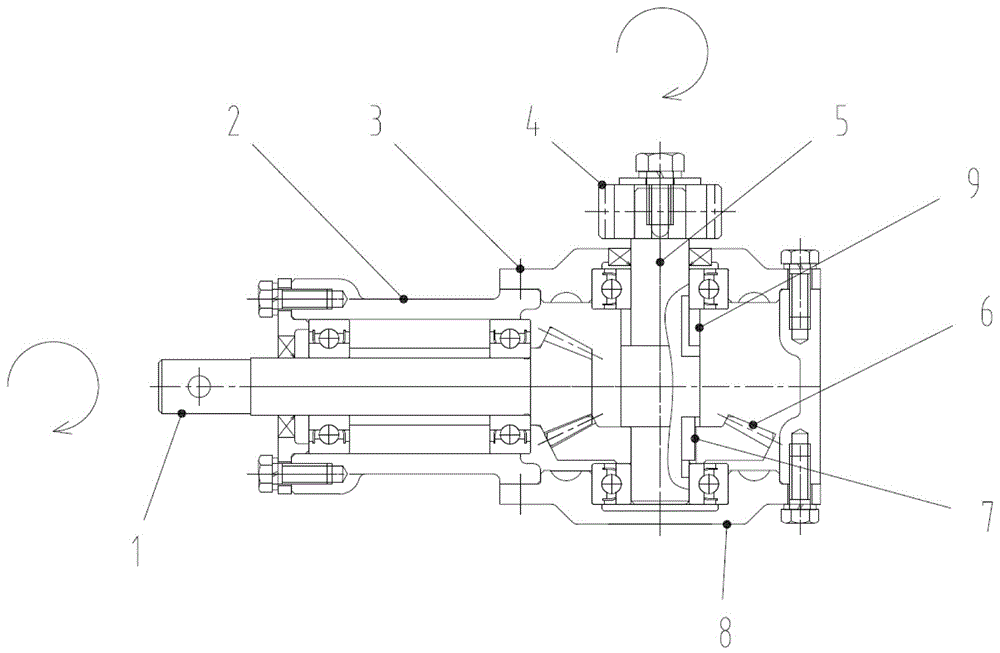

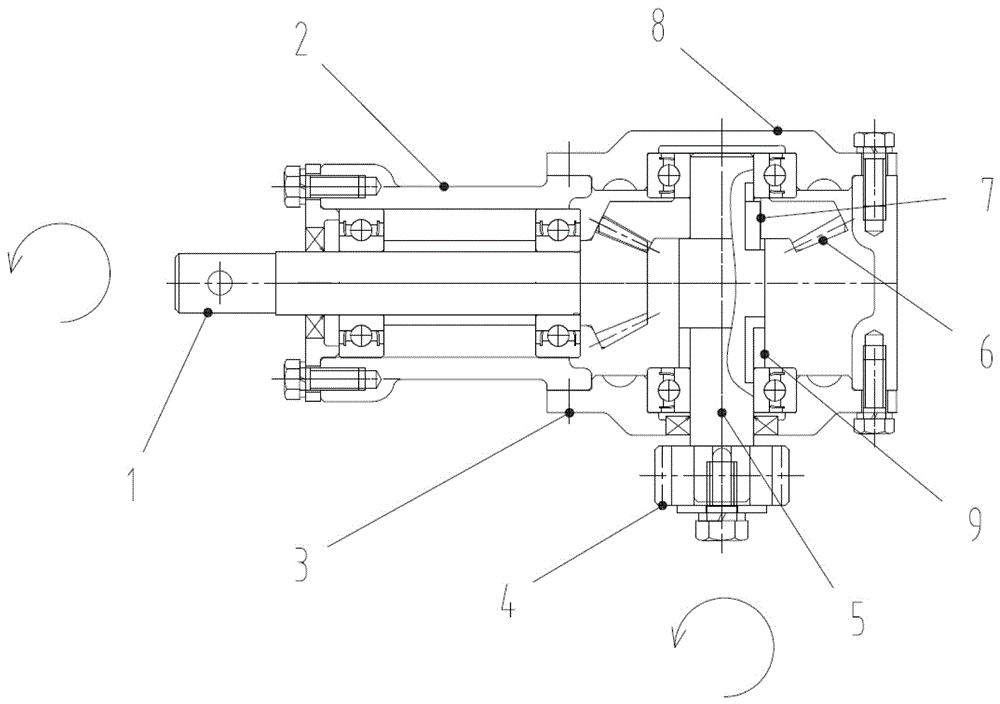

[0018] figure 1 It is a schematic diagram of the overall assembly structure of the gear reducer, Figure 5 for figure 1 Schematic diagram of the connection structure between the main components. Illustration: a universal transposition gear reducer, including input gear shaft 1, gear box body 2, bevel gear 6, output shaft 5 and output gear 4, characterized in that: the input gear shaft 1 is fixed by two bearings In the gear box, one end is connected with the drive shaft of the machine head, and the other end of the bevel gear placed in the gear box 2 is meshed with the bevel gear 6, and the power is transmitted from the drive shaft of the machine head. This is then passed to the bevel gear which meshes with the input gear shaft. In the gear box 2, the two ends of the output shaft 5 are respectively connected to the inside of the first end cover 3 and the second end cover 8 of the gear box 2 through bearings, and between the two bearings, the output shaft 5 One end is connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap