Method, control device and drive device for detaching a charge stuck to the inner wall of a grinding pipe

A technology of a driving device and a control device, which is applied to the driving device of the grinding tube and the field of the tube mill, can solve the problem of time-consuming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

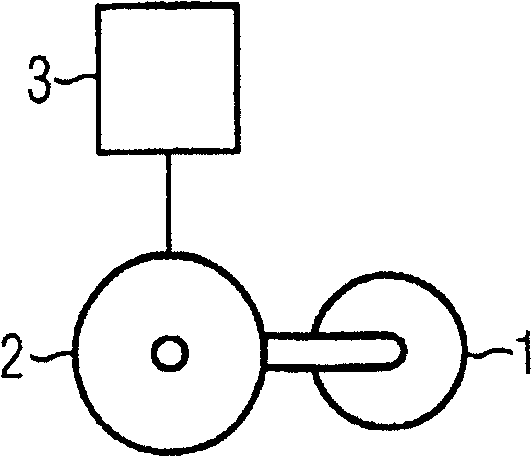

[0027] figure 1 A schematic structure of, for example, a tube mill for grinding ore is shown. The tube mill has a grinding tube 1 connected to a drive 2 . Furthermore, there is a control device 3 which sends control or regulating signals to the drive device 2 . The control device 3 can also receive and process signals, for example measurement signals from the drive device 2 or other components of the tube mill. The grinding tube 1 is preferably formed in the form of a drum. The tube mill has a support device (not shown in detail in the drawing) for grinding the tube 1 .

[0028] The drive 2 of the tube mill has at least one electric motor, for example designed as a ring motor. The electric motor is coupled to a converter, not shown in detail. The characteristic of the electric motor as a ring motor is that it can drive the grinding tube 1 without a gear and thus enables a particularly robust operation of the tube mill.

[0029] The drive 2 is preferably designed as a fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com