Pipeline cutting machine for water conservancy project

A technology of pipe cutting machine and water conservancy project, which is applied in the field of pipe cutting machine for water conservancy engineering, can solve the problems of easy vibration, uneven cutting, and the effect of circular pipe cutting and smoothing, and achieve the effect of preventing sliding and avoiding unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as Figure 1-Figure 5 Shown:

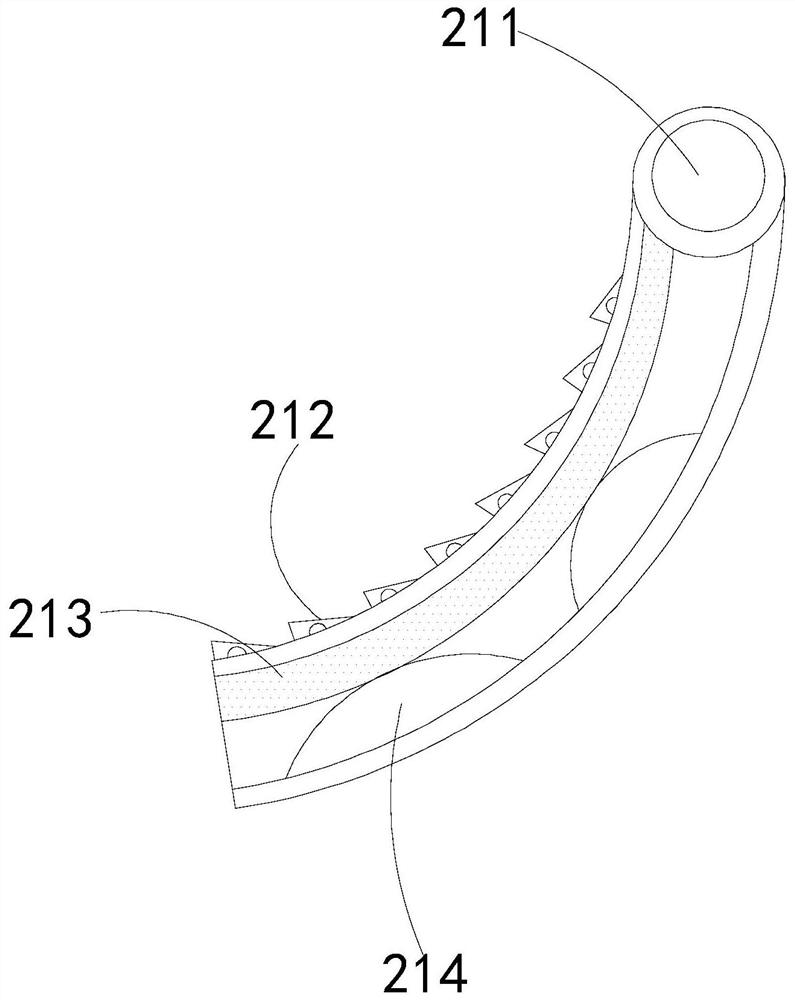

[0024] The invention is a pipe cutting machine for water conservancy engineering, its structure includes a motor 1, a fixing device 2, a holder 3, and a control switch 4, the motor 1 is installed on the left side of the upper end of the holder 3, and the control switch 4 is embedded On the surface of the fixture 3, the fixture 2 is installed on the left side of the lower end of the fixture 3, and the fixture 2 is provided with a supporting mechanism 21, a rotating mechanism 22, a supporting rod 23, and a fixing seat 24, and the supporting mechanism 21 Embedded in the upper end of the support rod 23, the rotating mechanism 22 is installed on the inner side of the fixed seat 24, and the support mechanism 21 is located inside the fixed seat 24. There are two supporting mechanisms 21, which are arc-shaped structures, attached to Closed on the lower surface of the circular pipe to support the circular pipe.

[0025] Wherein, the supporti...

Embodiment 2

[0031] Such as Figure 6-Figure 7 Shown:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com