Intelligent scraper device for laser selective melting SLM

A technology of laser selective melting and scraper device, applied in the field of additive manufacturing, can solve the problems of prominent melting point, uneven powder, affecting the quality of the formed workpiece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

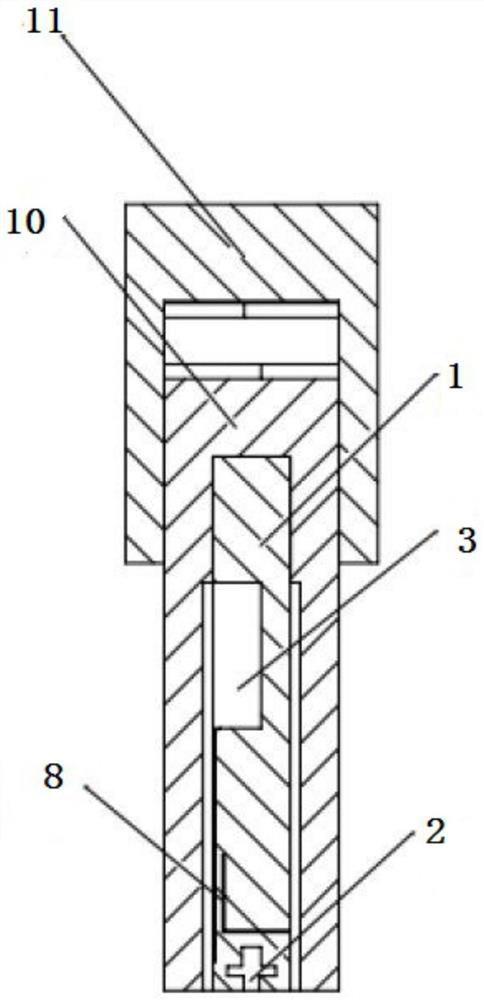

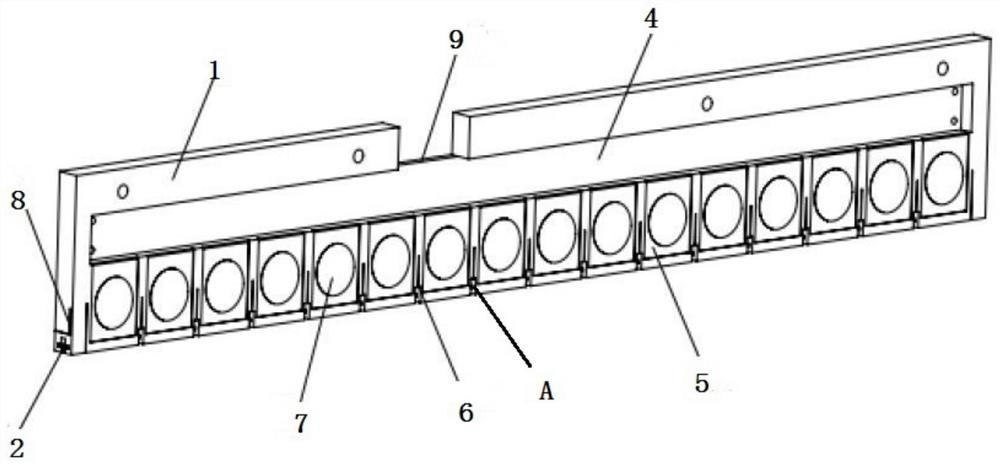

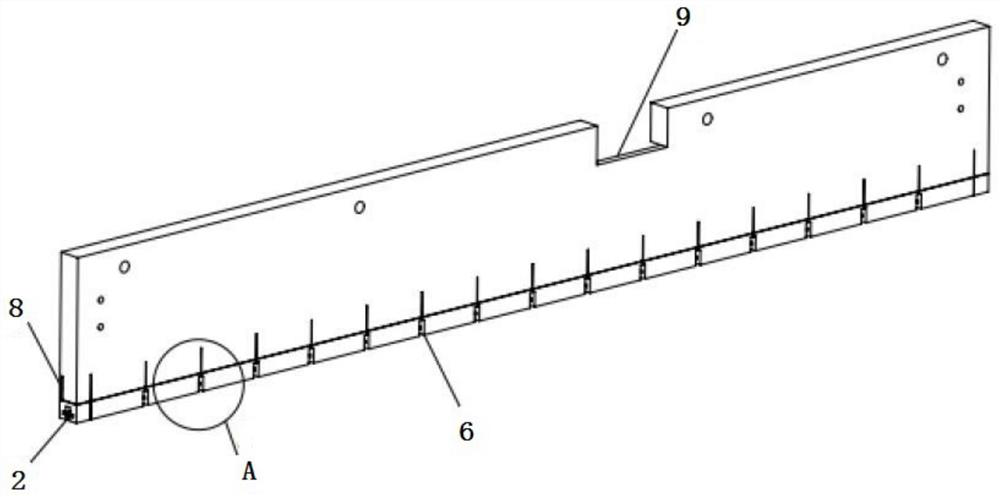

[0033] When the powder-spreading rubber strip encounters workpiece protrusions or uneven powder and deforms during the powder-spreading process, the piezoelectric sheet will generate a piezoelectric signal, and the structure of the inner core of the scraper can better transmit the deformation of the rubber-spreading strip to the The piezoelectric sheet makes the piezoelectric signal more sensitive; moreover, each piezoelectric sheet can output piezoelectric signals at different positions relatively independently. Level, the output piezoelectric signals on both sides of the scraper are inconsistent. The invention can fine-tune the level of the scraper by adjusting the nut, so as to accurately monitor the quality of powder spreading and the surface quality of parts during the molding process, and accurately control the levelness of the powder spreading scraper.

[0034] like Figure 1-Figure 6 As shown, this solution provides an intelligent scraper device for selective laser mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com