Material transferring method for cylinder sleeve machining

A transfer method and cylinder liner technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inability to achieve large-scale, intelligent production, time-consuming and labor-intensive, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

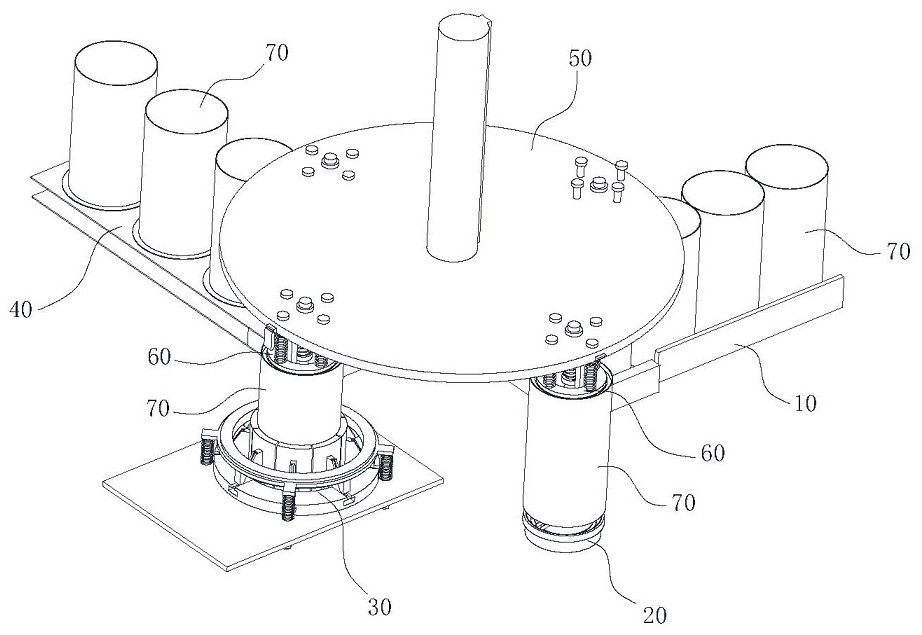

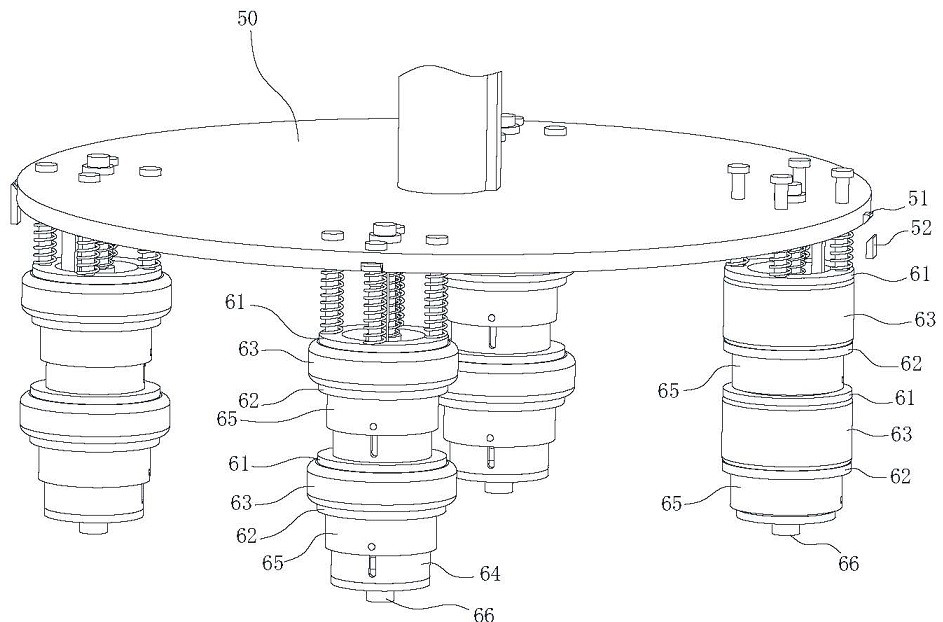

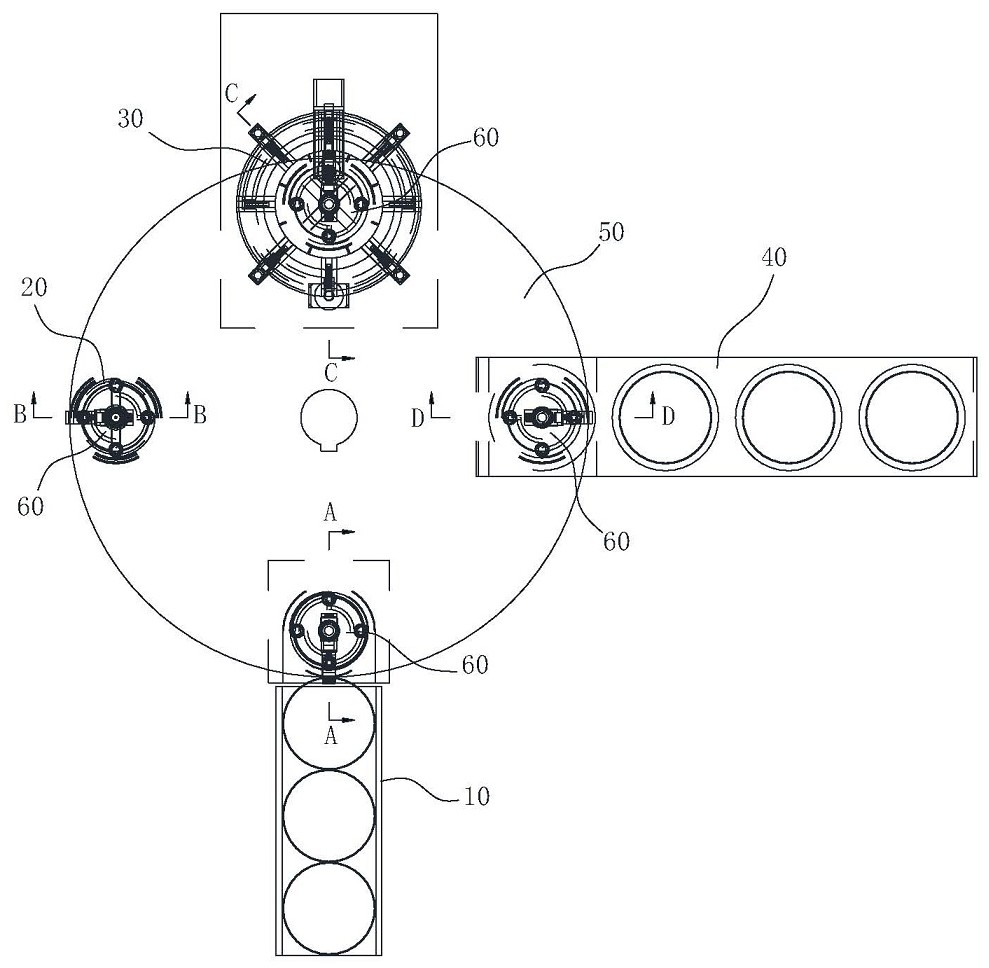

[0030] Such as figure 1 , 3 As shown, a cylinder liner processing system includes a transfer manipulator, and the transfer manipulator includes a circular mounting plate 50. The center of the mounting plate 50 is provided with a rotating shaft. Sliding connection, the frame is provided with a driving element for driving the hand to rotate and slide, the edge of the mounting plate 50 is provided with a clamping unit 60, and the revolving path of the clamping unit 60 is sequentially provided with a reclaiming station and an oiling station , flanging station and unloading station, the reclaiming station is provided with a cylinder sleeve blank conveying trough 10, the oiling station is provided with an oiling device 20, the flanging station is provided with a flanging device 30, and the unloading station The unloading conveyor belt 40 is provided at the station, and the clamping unit 60 clamps the cylinder liner 70 shell blank from the retrieving station, and transfers the cylin...

Embodiment 2

[0039] A method for processing a cylinder liner using the processing system described in Embodiment 1, comprising the steps of:

[0040] Step 1: placing the cylinder liner 70 on the conveying trough 10;

[0041] Step 2: Transfer the barrel blank of the cylinder liner 70 to the oiling station, and oil the inner ring surface of the end of the cylinder liner 70 to be flanged;

[0042] Step 3: transfer the oiled cylinder liner 70 to the flanging station, and perform flanging treatment on the cylinder liner 70;

[0043] Step 4: Transfer the flanged cylinder liner 70 to the unloading station and release the cylinder liner 70 onto the unloading conveyor belt 40 .

Embodiment 3

[0045] A material transfer method for cylinder liner processing, using a manipulator to clamp the cylinder liner 70 from the inside of the cylinder liner 70, and sequentially transfer the cylinder liner 70 through the oiling station, flanging station and unloading station, and The unloading station releases the cylinder liner 70; the manipulator includes a circular mounting plate 50, and the center of the mounting plate 50 is provided with a rotating shaft. There is a drive element for driving the hand to rotate and slide, the edge of the mounting plate 50 is provided with a clamping unit 60, and the revolving path of the clamping unit 60 is sequentially provided with a reclaiming station, an oiling station, and a flanging station and the unloading station, the reclaiming station is provided with a cylinder liner 70 and the barrel conveying trough 10, the oiling station is provided with an oiling device 20, the flanging station is provided with a flanging device 30, and the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com