Method for iron regulation and passivation of crude oil in som directional oxidation soil and passivation soil

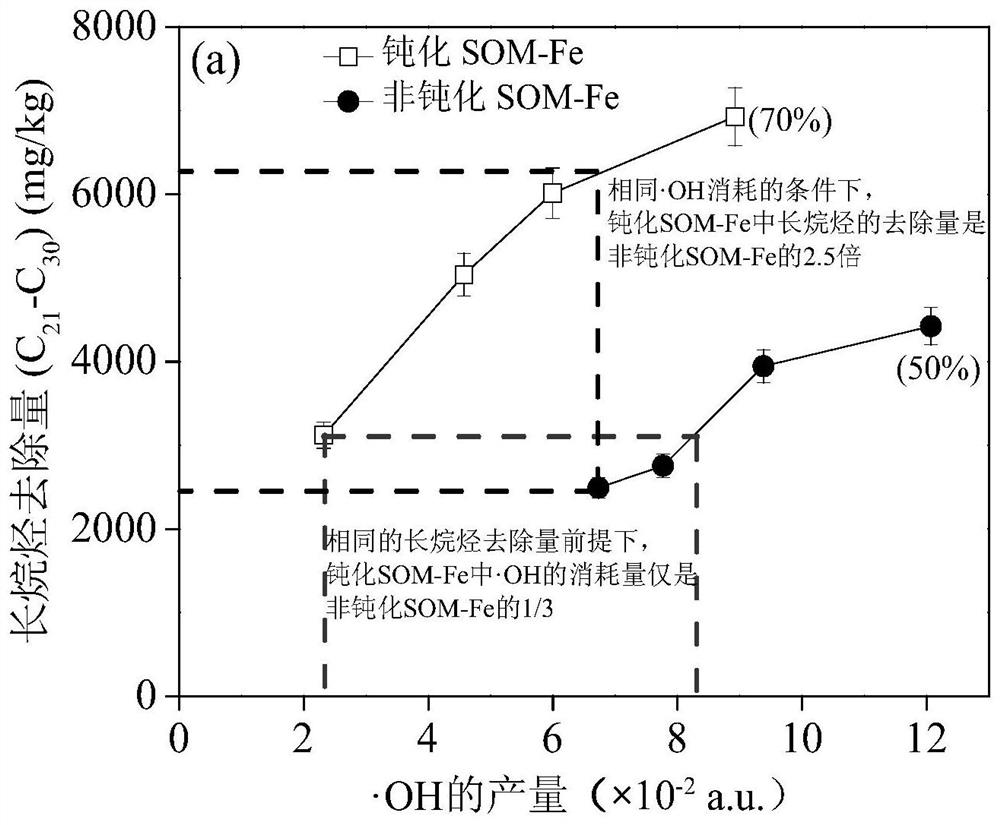

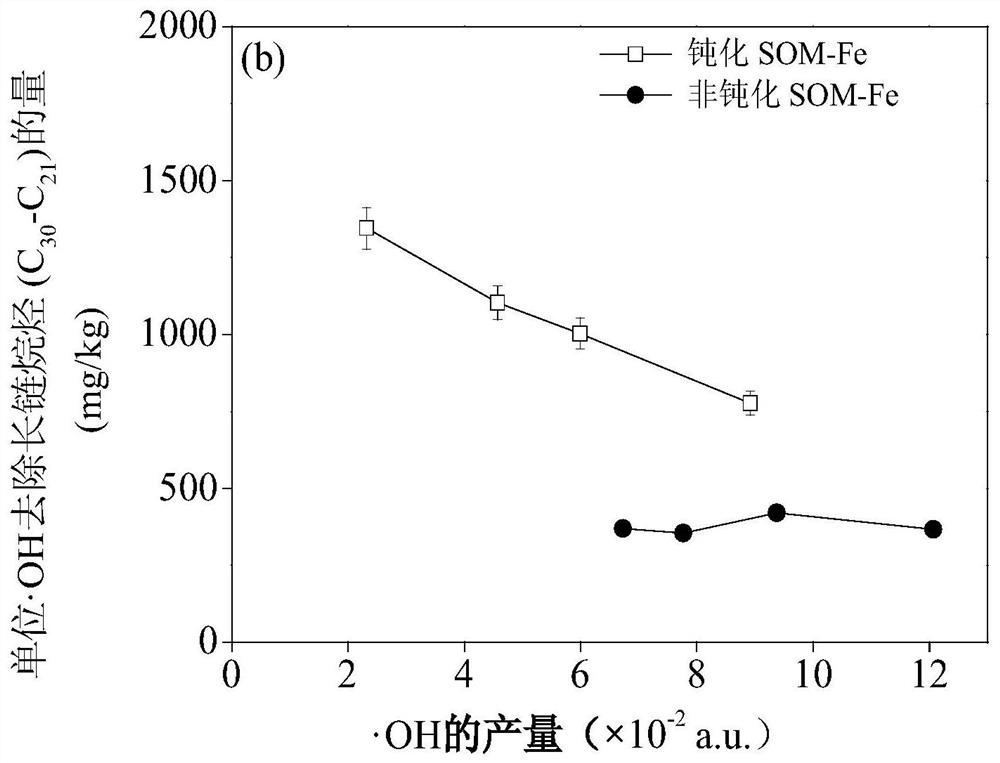

A technology for iron regulation and soil application in the direction of chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve the problems of increased costs, consumption of free radicals, low oxidation of petroleum hydrocarbons, etc., and achieve directional oxidation improvement , the effect of good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Passivation of organic matter in oily soil

[0052] According to the mass ratio, mix the oil-containing soil, the concentration of 2.9mmol / L ferric sulfate, the concentration of 50mmol / L hydrogen peroxide passivator and water 60:0.2:1.0:50, control the pH to 7, and rotate at 130r / min at room temperature Shake and react for 24 hours, filter and centrifuge, and freeze-dry the filtrate at -50°C to obtain passivated oil-bearing soil.

[0053] 2) Mix the passivated oily soil obtained in step 1) with the oxidant and water according to the mass ratio of 50:0.4:60, place it on an oscillator for continuous oscillation to carry out the directional oxidation reaction, and react for 36 hours at room temperature to complete the passivation controlled by iron Process of SOM directed oxidation of crude oil in soil.

[0054] After the reaction, the amount of directional oxidation of petroleum hydrocarbons was as high as 650 mg / kg, the functional group carbonyl in SOM was passivated...

Embodiment 2

[0056] The ferrous salt used is ferrous chloride of 5.8mmol / L, and the passivating agent is sodium hydroxide of 5mmol / L.

[0057] 1) Passivation of organic matter in oily soil

[0058] According to the mass ratio, mix oily soil, ferrous chloride with a concentration of 5.8mmol / L, sodium hydroxide passivator with a concentration of 25mmol / L, and water 70:0.1:0.6:55, and control the pH to 7. Shake and react for 36 hours at a rotational speed of 135r / min, filter and centrifuge, and freeze-dry the filtrate at -50°C to obtain passivated SOM oily soil.

[0059] 2) Mix the passivated SOM oil-containing soil obtained in step 1) with the oxidant and water according to the mass ratio of 60:0.5:80, place it on an oscillator for continuous oscillation oxidation reaction, and react for 24 hours at room temperature to complete the iron-regulated passivation SOM Process of directed oxidation of crude oil in soil.

[0060] After the reaction, the amount of directional oxidation of petroleum...

Embodiment 3

[0062] The ferrous salt used is 8.7mmol / L ferric sulfate, and the passivating agent is 100mmol / L sodium hydroxide.

[0063] 1) Passivation of organic matter in oily soil

[0064] According to the mass ratio, mix the oil-containing soil, the molar concentration of 8.7mmol / L ferric sulfate, the molar concentration of 100mmol / L sodium hydroxide passivator and water 50:0.3:0.5:70, control the pH to 7, and rotate at room temperature Shake and react at 140r / min for 48h, filter and centrifuge, and freeze-dry the filtrate at -50°C to obtain passivated SOM oily soil.

[0065] 2) Mix the passivated SOM oily soil obtained in step 1) with the oxidant and water according to the mass ratio of 40:0.4:100, place it on an oscillator for continuous oscillating directional oxidation reaction, and react for 48 hours at room temperature to complete the iron-regulated passivation Process of SOM directed oxidation of crude oil in soil.

[0066] After the reaction, the amount of directional oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com